| ID |

Date |

Author |

Type |

Category |

Subject |

|

633

|

Tue Aug 26 12:14:24 2025 |

Liu | Update | Interferometer Simulations | Multi-ring FROSTI design for A# with ring heater optimization |

| Multi-ring FROSTI design for A# with ring heater optimization |

| Attachment 1: Update_(1).pdf

|

.png)

|

|

632

|

Tue Aug 19 12:33:59 2025 |

Pooyan | Update | TCS | A# BS Update |

|

| Attachment 1: A#_beamsplitter_thermal_lensing.pdf

|

|

|

631

|

Tue Aug 19 12:08:40 2025 |

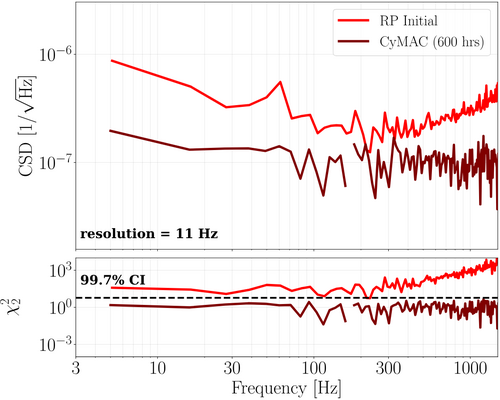

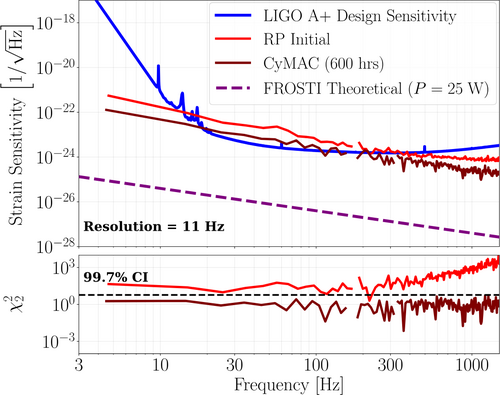

Christina | Update | TCS | RP Initial vs CyMAC Plot Comparisons |

| [Tyler, Ma, Christina]

These are the frequency averaged and veto binned plots for the initial Red Pitaya and CyMAC systems. |

| Attachment 1: 11hzCSD.png

|

|

| Attachment 2: 11hzstrain.png

|

|

|

630

|

Tue Aug 12 13:49:24 2025 |

Mary | Update | | point absorber and coated aperture in A# |

|

| Attachment 1: Aug12.pdf

|

|

|

629

|

Tue Aug 12 13:46:56 2025 |

Christina | Update | | |

|

| Attachment 1: 3.png

|

|

| Attachment 2: 3-1.png

|

|

|

628

|

Tue Aug 12 13:32:43 2025 |

Liu | Update | Interferometer Simulations | |

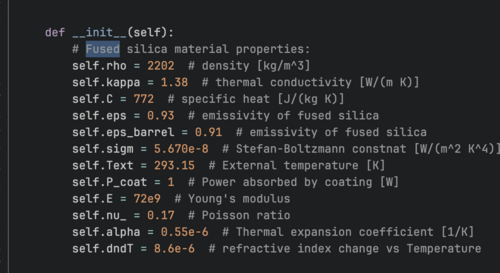

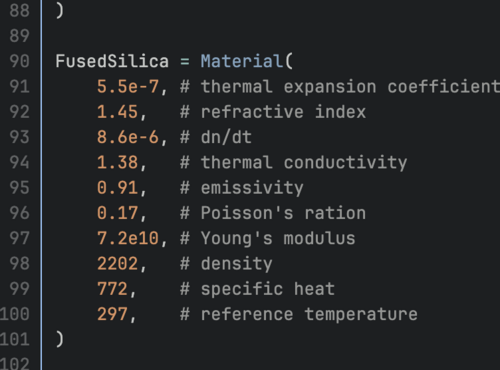

| Differences in Fused Silica parameters. |

| Attachment 1: Screenshot_2025-08-12_at_1.31.11_PM.png

|

|

| Attachment 2: Screenshot_2025-08-12_at_1.31.17_PM.png

|

|

|

627

|

Tue Aug 12 13:28:00 2025 |

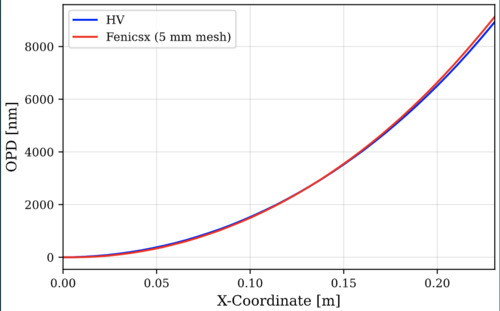

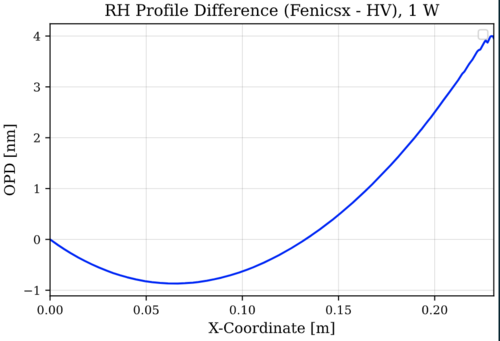

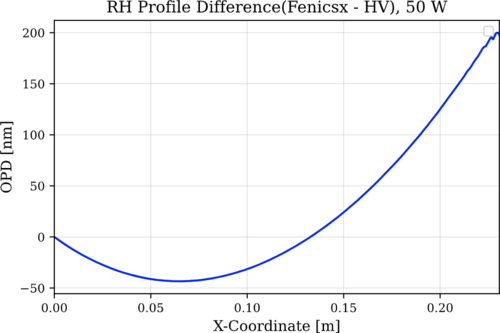

Tyler | Update | TCS | RH Fenicsx v. HV |

|

| Attachment 1: Profile_comparison.png

|

|

| Attachment 2: 1W_diff.png

|

|

| Attachment 3: 50W_diff.png

|

|

|

626

|

Tue Aug 12 12:35:19 2025 |

Tyler | Update | | CyMAC ADC Update |

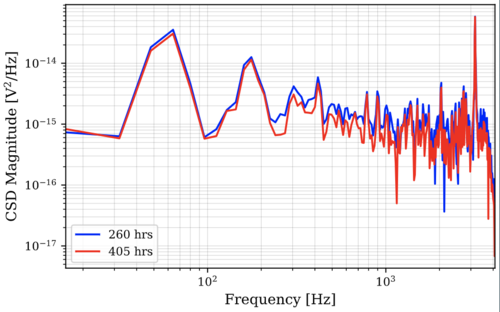

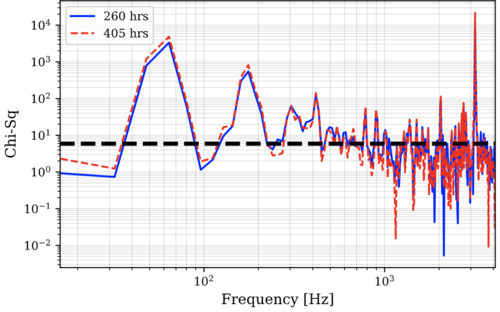

| [Christina, Ma, Tyler]

Updated CyMAC measurement, comparing 260 hrs of measurement time vs. 405 hrs. |

| Attachment 1: CSD_magnitude.png

|

|

| Attachment 2: chi_sq.png

|

|

|

625

|

Tue Aug 12 12:16:21 2025 |

Liu | Update | Interferometer Simulations | Multi-ring FROSTI optimization for A# |

| Multi-ring FROSTI optimization for A# with static polishing |

| Attachment 1: Update.pdf

|

|

|

624

|

Mon Aug 11 22:19:50 2025 |

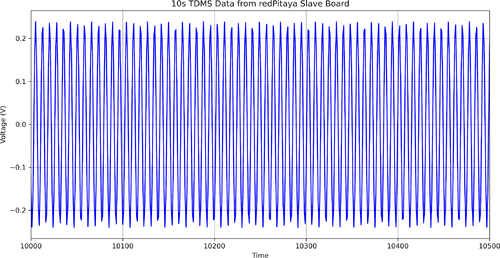

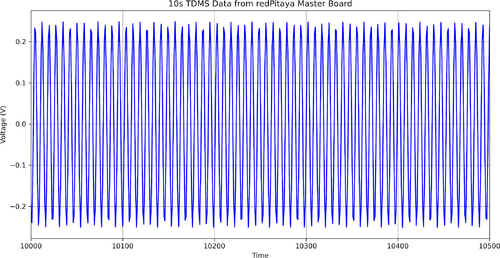

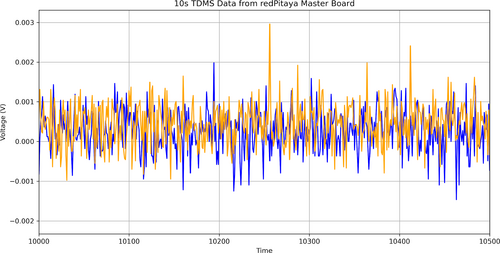

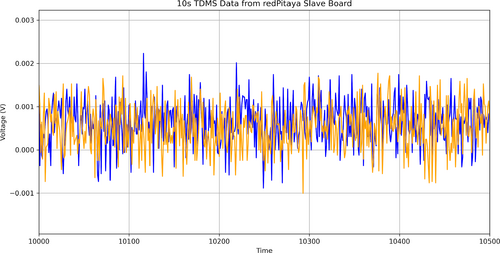

Christina | Update | TCS | Red Pitaya Data Streaming |

[Ma, Tyler, Christina]

This past week, we were able to set up the data streaming for continuous acquisition to the PCs, and can conduct the initial tests now. We were able to do this by:

- Installing the correct OS ecosystems to each Red Pitaya

- Installing the terminal streaming client

- Debugging formatting and file saving issues by saving the data in a TDMS file on the host PC.

We have started streaming the ADC data on Monday from both boards for 2 days, which are currently in the clean room. Below are the ADC tests we performed before starting the 2-day run. (Time in ms) |

| Attachment 1: 3.png

|

|

| Attachment 2: 3-1.png

|

|

|

623

|

Wed Aug 6 16:31:37 2025 |

Xuesi Ma | Update | | |

|

Date and Time: Around 4:20 PM on Auguest 6, 2025

Location and Temperature:

- Back of the room 1119, around the working station: 90.2 °F

- Front of the room 1119, around the doorway: 85.8 °F

- Back of the room 1129, around the working station: 93.4 °F

- Front of the room 1119, around the doorway: 82.3 °F

- In the hallway in front of room 1119: 77.2 °F

|