| ID |

Date |

Author |

Type |

Category |

Subject |

|

399

|

Tue Jul 9 18:19:50 2024 |

Shane | Update | CDS | ADC-DAC loopback testing and IOLAN installation |

| [Shane, Jon]

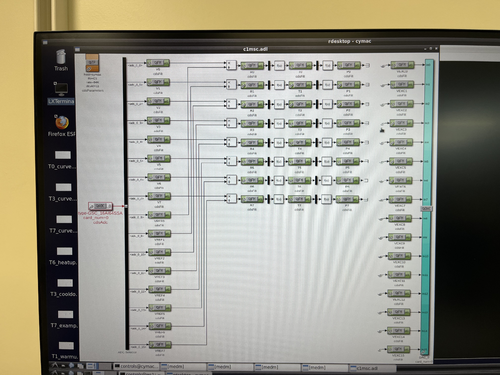

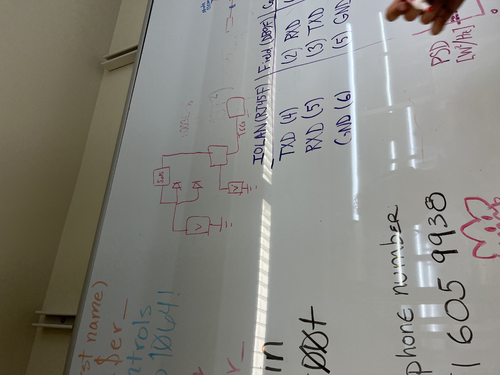

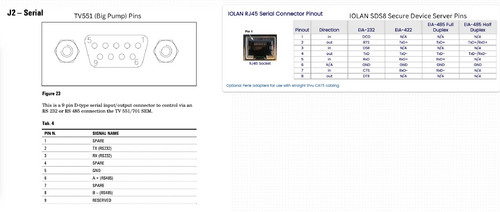

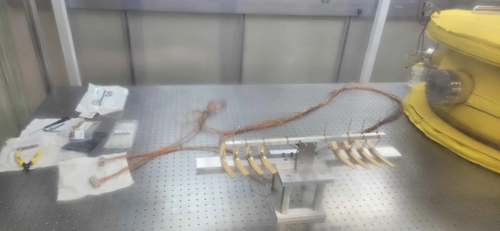

Finished ADC-DAC loopback testing today (see attached xlsx file or access directly here). All looks well with the first 8 channels, with the gain hovering just under 2. Also edited c1msc model in simulink to add channels 7-15 (the last 8 channels), and changed the rate back to 64K. See image 1 for the updated c1msc model. The last 8 channels are also looking good and show no problems, with slightly more scattering for the gain, but all values very close to 2.

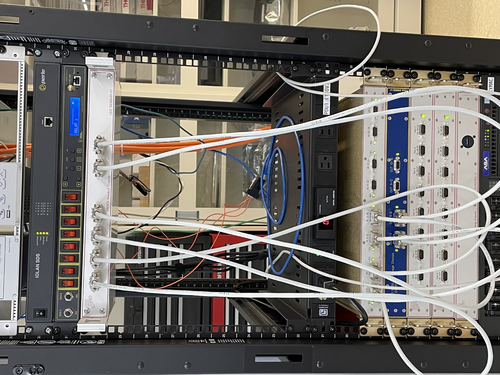

We also installed the new eight-channel Perle IOLAN SDS8 terminal server today. Image attached.

NOTE: When we were installing it, we noticed an energized wire dangling from the 24V power supply. Has since been fixed and put back into place. |

| Attachment 1: iolanServerTerminal.jpeg

|

|

| Attachment 2: ADC-DAC_Loopback_Testing.xlsx

|

| Attachment 3: updatedc1msc.jpeg

|

|

|

410

|

Tue Jul 16 18:43:07 2024 |

Shane | Update | CDS | ADC-DAC loopback testing and IOLAN installation |

|

UPDATE:

Follow up ADC-DAC loopback testing now complete, matching all the ADC channels to a single DAC channel, and then matching all the DAC channels to a single ADC channel (see attached xlsx file or access directly here). Also note c1msc model file has been updated to include the second set of 16 ADC channels. The newly added channels also have their own filter modules, but those are not needed for anything other than the loop-back testing and can now be deleted if we don't want to keep them.

| Quote: |

| [Shane, Jon]

Finished ADC-DAC loopback testing today (see attached xlsx file or access directly here). All looks well with the first 8 channels, with the gain hovering just under 2. Also edited c1msc model in simulink to add channels 7-15 (the last 8 channels), and changed the rate back to 64K. See image 1 for the updated c1msc model. The last 8 channels are also looking good and show no problems, with slightly more scattering for the gain, but all values very close to 2.

We also installed the new eight-channel Perle IOLAN SDS8 terminal server today. Image attached.

NOTE: When we were installing it, we noticed an energized wire dangling from the 24V power supply. Has since been fixed and put back into place. |

† |

| Attachment 1: Follow-up_ADC-DAC_Loopback_Testing.xlsx

|

|

419

|

Fri Aug 2 13:50:22 2024 |

Shane | Update | CDS | Serial Comm. Test (Agilent Turbo Pump) |

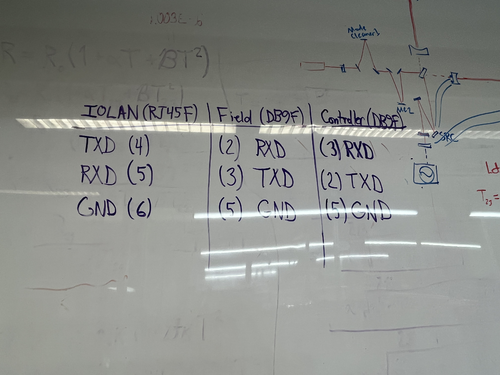

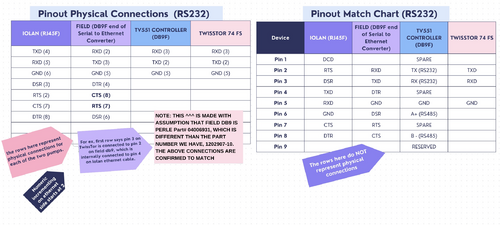

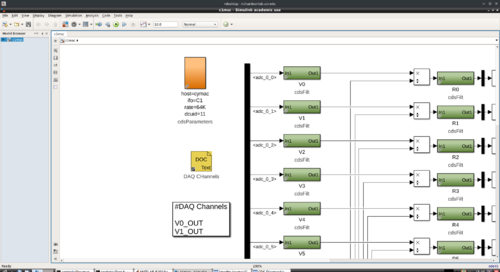

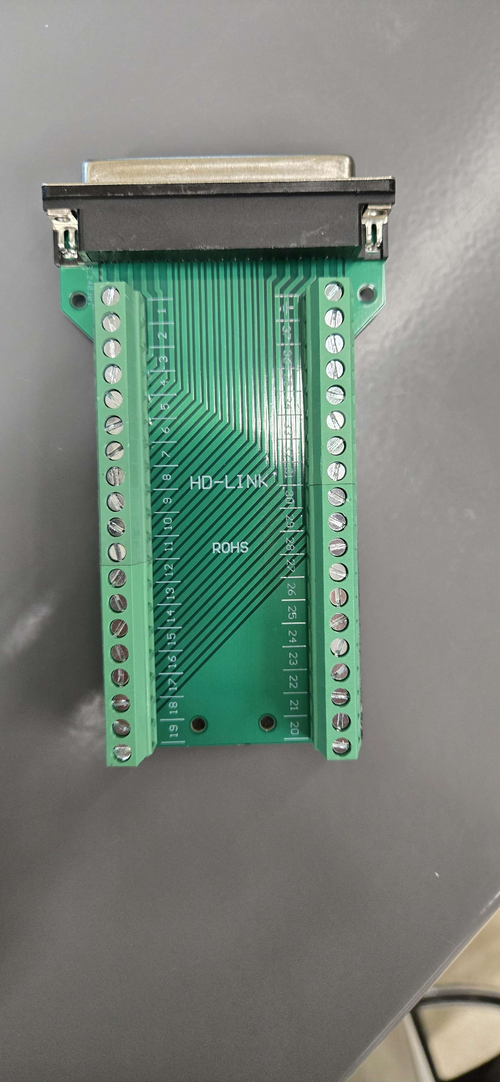

| Did a brief communication test with the agilent turbo pump today, to see if we could get serial communications up and running for it. Used a simplified python script with sockets package to establish a connection and send a simple command to query the pump's operational status. The connection was successful, and had no issues establishing. The command also sent successfully, and received a response. The response didn't make sense, though, as all the possible statuses correspond to integers 0-7, and this test returned the integer 15. Need to troubleshoot some more to figure out why it's returning nonsense values. Possible match-up issue with the way the information is being encoded on each end? At the very least, connection and command sending are both working fine, and this showed that the pin-out connections we were assuming (image attached) are correct for basic connection to work. |

| Attachment 1: pinouts.jpeg

|

|

|

434

|

Tue Sep 3 18:24:17 2024 |

Tyler | Update | CDS | Cymac Timing Chassis Issue |

| [Tyler, Jon]

The timing chassis used for the cymac has been shut off due to an unknown issue causing its supplied current to fluctuate. All real-time models will be suspended until a solution is found.

|

|

Draft

|

Tue Oct 1 19:41:23 2024 |

Shane | Update | CDS | CyMAC Timing Chassis Issue |

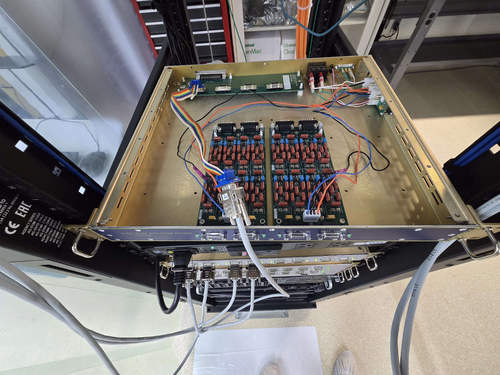

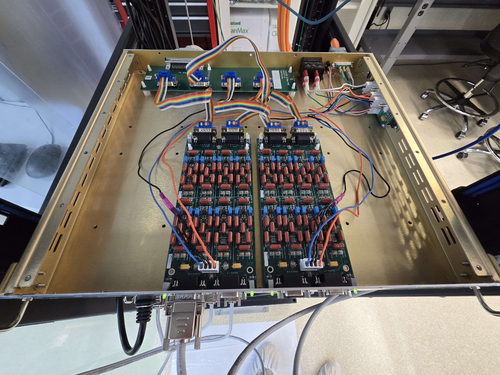

| [Shane, Luis]

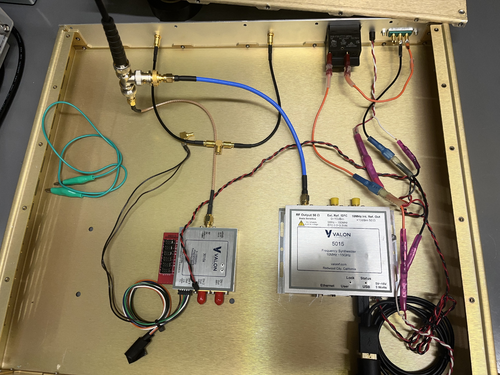

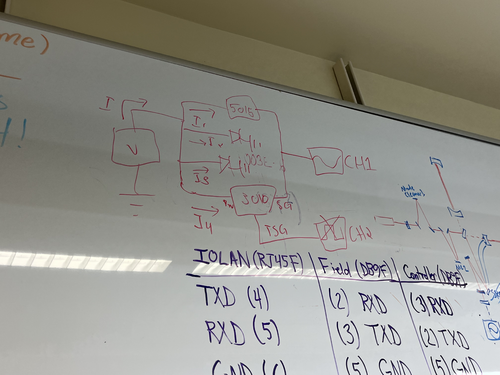

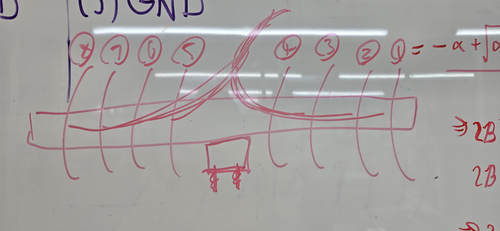

Summary of the issue we've been having with the timing chassis: when we connect only the Valon 5015 to power, the timing signal comes out of it sinusoidal as expected and the status lights are steady and all looks good. As soon as we connect the 3010 to power, the signal (both coming out of the 5015 and coming out of the 3010) go flat and the status lights of the 5015 start to flicker.

We think what may be going on is that the 5015 is drawing just enough power to survive on its own, but when the current gets split to go to the 3010 as well, the 5015 takes more than it needs and becomes overpowered, and thus no longer outputs anything. We want to test further by powering them with two separate power supplies, but we need another one of the power connectors for the 3010 (the only one we have branches out from the connector to the 5015 and we don't want to cut any of the wires).

Images of the inside of the chassis, along with two roughly sketched circuit diagrams (one showing the current setup, in which they're powered by the same source, and one showing a possible test set up, in which they're powered separately. |

| Attachment 1: IMG_5917.jpeg

|

|

| Attachment 2: IMG_5803.jpeg

|

|

| Attachment 3: IMG_5804.jpeg

|

|

|

461

|

Thu Oct 17 13:24:23 2024 |

Shane | Update | CDS | Timing Chassis issue identified |

|

[Ma, Luis, Shane]

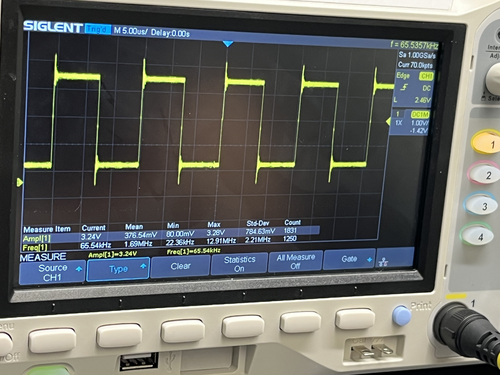

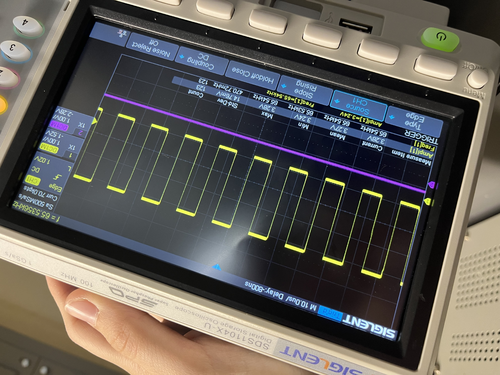

Working theory for the timing chassis issues had been that the 1A breaker was tripping and causing the failure of the Valon 5015 and 3010 to output the timing signal correctly. We just tried bypassing the breaker, running 6 V on the benchtop power supply (set the current limit to 1.5A), with the 5010 generating the sine wave to pass to the 3010. All worked correctly, and there were no issues. Square wave outputted by the 3010 was exactly as desired (image attached) at the correct frequency, and this confirms the issue was the breaker, not the valon 5015. Ready to go ahead with ordering a new replacement breaker.

|

| Attachment 1: IMG_6462.jpeg

|

|

| Attachment 2: IMG_6464.jpeg

|

|

|

465

|

Fri Oct 25 10:56:30 2024 |

Shane | Update | CDS | Timing Chassis fixed and reinstalled |

|

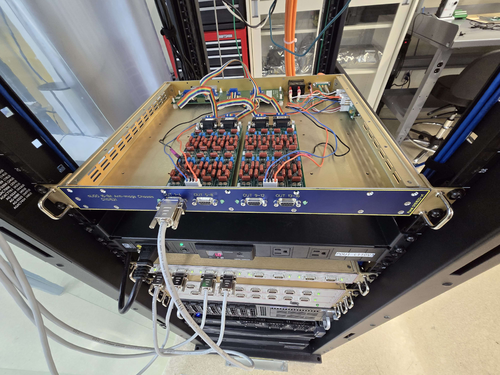

[Ma, Shane]

We replaced the 1A breaker in the timing chassis today with a 4A one, and tested that all is working well. The chassis successfully outputted the correct signal (image attached). The real time models have also been restarted and the CyMAC diagnostics screen is showing all green flags. Timing chassis has been closed up and reinstalled in the server rack.

|

| Attachment 1: successful_timing.jpeg

|

|

|

473

|

Thu Nov 14 11:58:05 2024 |

Shane | Update | CDS | Turbo pump connection troubleshooting |

| Attempted connection to the TV551 turbo pump through Varian/Agilent's software on spica. Successful connection established, and we are able to read out al the readings associated with the pump (status, temperature, etc) through the software, which is actually pretty extensive and well organized. Was able to stop and restart the pump with no issues. Serial communications seem to be working fine, and the current serial settings (baud rate 9600, serial type RS232) all match what the Iolan was expecting with the previous connection test. Also notable: the code used for the previous (failed) connection test is written using 'Letter protocol', which is the older of the two communications protocols supported by these kinds of pumps. This rules out the pump being too old to accept the newer communication format as the issue, since it's the older format being used anyway. Will continue trouble shooting to determine why previous connection test failed. |

|

484

|

Wed Dec 4 16:01:23 2024 |

Shane | Update | CDS | Vac serial interfacing troubleshooting update |

| Update on the issue with serial interfacing for the TV 551 turbo pump: Tried a new test today, to see if the commands being sent to the controller were actually getting through at all, since we know that no response is getting back to us. To test this, I sent the start/stop command for the pump, disconnected the serial connection and instead connected the controller to spica so I could run the manufacturer's software, and used the manufacturer's sotware to check the pump status manually. After trying a few variations of this test, during which the pump status did not change at all from 'normal' (meaning the stop command being sent was not actually received), we've concluded that the commands being sent to the pump with the serial comms code are not being received. Further troubleshooting needed. |

|

505

|

Tue Jan 28 13:30:46 2025 |

shane | Update | CDS | Serial comms testing update |

| Attempted to communicate with the smaller vac pump (TwissTor 74) via Agilent software today. Was able to communicate with the pump via python serial connection code as usual, with no issues. When using the manufacturer software though, it was unable to 'locate' the pump and failed to connect to it. So manufacturer software works for the big (older) pump, but not the smaller, newer one. Unclear if this is somehow related to the fact that using the manufacturer software for the bigger pump involved manually connecting its controller to spica with a db9, and there was no obvious way to do that for the smaller pump's controller. |

|

518

|

Wed Feb 19 13:44:48 2025 |

Shane | Update | CDS | Vac serial interfacing update |

|

[Jon, Shane]

Debugging update for vac system serial communications: we were able to successfully connect the smaller turbo pump to the Varian (manufacturer) software today by plugging the controller db9 directly into spica, and verified that the pump was able to send and receive information. Still no success on communication with the larger pump via python serial code, though. Issue potentially lies in the pinout mapping of the connectors, as the pinouts we'd been using work successfully for the small pump which only requires 3 connections (RXD, TXD, GND), but the large pump may require more. Tried to test this on the big pump by keeping the pinout setup for the small pump, and incrementally adding the remaining 6 connections on a one to one scale (Pin 1 matched to Pin 1, etc) between the controller DB9 and the field DB9 connected to the IOLAN ethernet cable. After each new connection was added, I retried running the serial connection code. None of the additional connections yielded any results, and the large pump remained unable to connect through the code. Next step is further looking into documentation on the pinouts to see if the large pump requires a different connection setup than the small pump.

|

|

527

|

Thu Feb 27 18:22:21 2025 |

Shane | Update | CDS | Ongoing work in server rack and desk area (1119) |

| As part of the vacuum communications debugging process, there is ongoing work in the server rack and desk area in 1119. Please be careful not to move any of the materials left out in the server rack or on the work bench. |

|

532

|

Tue Mar 4 10:47:03 2025 |

Shane | Update | CDS | Vac system pinouts |

| Attached here are the pinouts, as we currently know them, for the vacuum system. The three items focused on here are the Agilent TwissTorr 74 FS turbo pump (the smaller/newer pump) and controller, the Agilent TV 551 Navigator turbo pump (the larger/older pump) and controller, and the Eight-channel Perle IOLAN SDS8 terminal server. The 'field' pinouts in the attached tables refer to the DB9 end of the RJ45F to DB9F converter. |

| Attachment 1: vac_pinouts_1.jpeg

|

|

| Attachment 2: vac_pinouts_2.jpeg

|

|

|

533

|

Wed Mar 5 12:16:28 2025 |

Shane | Update | CDS | Vac system communications update |

|

[Shane, Jon]

Update on the serial interfacing with the vacuum system: both turbo pumps are now able to successfully communicate through the code. The older pump, for unknown reasons, required a newer version of the communication syntax (despite the newer, small pump being able to communicate fine with the old communication format). We have also confirmed that the newer pump works with this new format as well. Next step is interfacing the pressure gauge.

|

|

534

|

Wed Mar 5 18:13:20 2025 |

Shane | Update | CDS | vac system comms |

|

[Shane, Jon]

Update on the serial interfacing with the Inficon VGC503 pressure gauge: We began setup of the Inficon pressure gauge today. We configured the ethernet setting via USB and assigned it a static IP address of 192.168.1.30, which is listed in the network table on the lab wiki. It is showing up on the network successfully, and is responding to pings. Will attempt communication via code next.

|

|

535

|

Mon Mar 10 17:03:52 2025 |

Shane | Update | CDS | Pressure Gauge successful connect |

| Vac system serial interfacing update: the pressure gauge is now able to communicate successfully through the code. It's been set to a static ip of 192.168.1.30, on port 8000. |

|

546

|

Thu Apr 3 13:23:37 2025 |

shane | Update | CDS | UPS interfacing |

| Update on UPS serial interfacing: the driver for the UPS webcard has been installed on spica (for UPS1 in room 1119) and logrus (for UPS2 in room 1129). Static IP addresses have been assigned for both and noted on the lab wiki. Neither is yet able to connect, as the initial ip address webpage connection test failed for both. In the process of troubleshooting now. |

|

565

|

Wed Apr 30 13:42:45 2025 |

Shane | Update | CDS | UPS comms successful |

| Update on UPS1 serial interfacing: communication is now successful. On 4/15/25 we connected to UPS1 via ethernet rather than USB, and manually added its static ip address (noted in lab network wiki) to the router. Able to connect and unpack all desired data nicely using telnet server connection via telnetlib. In process of finalizing code and will work next on interfacing UPS2. |

|

570

|

Tue May 6 12:25:03 2025 |

Tyler | Configuration | CDS | Cymac ADC CSD measurement |

| An initial measurement of the cymbal ADC CSD is attached below. As of now, it seems that the sensitivity limit is roughly the same as that of the Red Pitaya. |

| Attachment 1: cymac_adc_rin_v1.pdf

|

|

|

585

|

Tue Jun 3 11:50:08 2025 |

Pooyan | Update | CDS | CDS update |

There are three major issues with the lab's CDS system that should be addressed. They are ordered from the highest priority to the lowest.

- CyMAC has stopped serving the fast channels (65k Hz)

The channels are still there, and the data from the slow (16 Hz) channels is served correctly, but the fast data is not served. As a result, diagggui can not retrieve any information at the moment.

Probably the issue is the same as the version conflict between daqd and nds2-server. After installing nds2-server on CyMAC and realizing that the conflict can not be resolved, I reverted the changes so that the CyMAC could be compatible with daqd, but there is a chance that there are still version conflicts that block the fast channels.

I suspect that we have broken the MSC model when adding the new button. This could explain both the fasr-channels fault and the unexpected crashes.

UPDATE 6/5

Fixes this by rebuilding the models.

Note for the future: The c1iop and c1msc models should be rebuilt together, even if no change has been made to c1iop.

- The fast channels were not saved to the frames

Reviewing the frame files showed that the daqd was only saving the 16 Hz data in the .gwf frame files. I had missed this because I only checked the existence and the integrity of the raw frame files, but never retrieved the high-frequency data itself to check it.

- NDS2-server is installed, but does not distribute the data

I managed to install the nds2-server and its satellite programs on the Chimay, and NFS mount the frame files on it. The server successfully chaches the channel names, frame files, and the data, but fails to list the channels for distribution.

Note: CyMAC machine was strangely disconnected from the network, and required manual reboot. I couldn't find any abnormal logs that could explain what happened. |

|

590

|

Tue Jun 10 12:11:14 2025 |

Pooyan | Update | CDS | CDS update |

- The MEDM models issue was fixed. The issue was that building the c1msc model alone was not enough and we had to re-build the c1iop as well, although no changes has been made to the c1iop. Added a note in the wiki on this for future reference.

- For writing the fast channels to the frame files, our CDS system should have a GDS broadcaster. I followed this wiki page to set one, but it breaks the current daqd system. Asked about it earlier today on the CDS Mattermost channel and waiting for a response.

- Maybe I should continue the distributed scheme we have been trying for the nds2-server and let another machine on the network do this.

- Question: daqd has a feature to zero-out the bad data (NaNs), and it is currently on for our system. I don't think that it's a good idea to have this. Should I turn it off?

|

|

592

|

Wed Jun 11 16:19:37 2025 |

Pooyan | Update | CDS | CDS update |

- Fast channels recorded to .gwf frame files

- The fast channels are recorded with an extra _DQ in their names. So, in ndscope and diaggui these two channels should be addressed as

- C1:MSC-V0_OUT_DQ

- C1:MSC-V1_OUT_DQ

-

Update 6/13: enabled recording of all the ADC voltage channels so that Tyler can use all the data for the noise floor calculation. attached is an example of diagggui with almost 30 hrs of data.

|

| Attachment 1: Screenshot_20250611_154834.png

|

|

| Attachment 2: f3k.pdf

|

|

|

635

|

Tue Aug 26 12:45:41 2025 |

Christina, Ma, Tyler | Update | CDS | RIN Update |

| Slides |

|

8

|

Fri Jul 22 13:20:28 2022 |

Phoebe | Update | | Comsol |

| I will be using comsol until 1:30 pm today. I will be updating the model for the heater mount to be thicker in certain areas, so that it can feasibly be 3D printed. Specifically, the radius of the center cartridge mount has been increased to add thickness to the pipe and the arms of the bridge. This will allow us to print with a much smaller chance for error, as the printer can print objects with a minimum length of 1 mm. |

|

37

|

Tue Feb 28 19:33:51 2023 |

Peter | Update | | 532 M2 Measurements |

| Y axis of plot in units of micrometers. X axis in units of millimeters. |

|

46

|

Wed Mar 8 18:35:52 2023 |

Pamella | Update | | Lab cleaning |

| Today Pamella finished cleaning of the cleanroom, starting with the HEPA vacuuming, mopping and clearing all floor with IPA wipes.

Also Pamella and Julian finished cleaning of lab floor, starting with the HEPA vacuuming and mopping.

Shane and Pamella wiped down every surfaces of the laser table, computer table and the table with the vacuum pieces inside the cleanroom.

Shane, Peter, Tayler, Pamella and Julian then wiped down every surface of the laser table outside the cleanroom. We wiped the main tabletop as well as the legs and all parts for the table. We wiped the computer desk, the boxes, the cabinets and every part outside the cleanroom. For now we finished the lab cleaning. |

|

371

|

Fri May 31 19:37:47 2024 |

Luke | Update | | Vacuum chamber Disassembly |

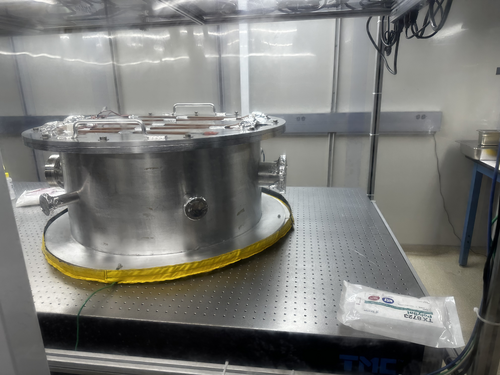

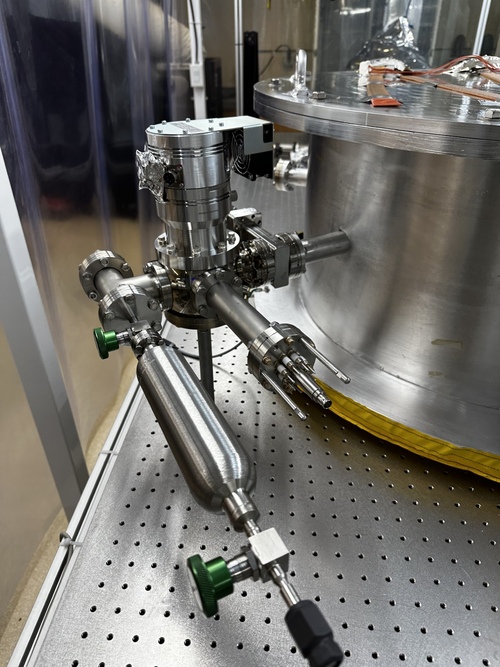

| [Luke, Aiden, Jon, Michel, Tyler]

Work done:

On Tuesday (5/28) we removed the RGA line with minimal difficulty. On Wednesday (5/29) we removed the turbo pump, which had a few bolts that we needed to cut. We borrowed a dremel with ceramic blades from the machine shop to help remove some of the bolts. On Thursday we moved the vacuum chamber onto the floor to check and resecure the heating band on the bottom of the vacuum chamber. We then relocated the posts the vacuum chamber rests on closer to the end of the table and reinstalled the chamber. The postís height was also reduced from 2in to 1in.

Current state of vacuum chamber:

The vacuum chamber is currently reinstalled in its new position. Some of the parts on the table will be used in the assembly of the turbo pump and RGA lines with the others being able to be moved to storage. |

| Attachment 1: IMG_1681.jpg

|

|

| Attachment 2: IMG_1680.jpg

|

|

| Attachment 3: IMG_1680.jpg

|

|

| Attachment 4: IMG_1681.jpg

|

|

|

378

|

Wed Jun 19 18:45:14 2024 |

Luke | Update | | Vacuum chamber reassembly |

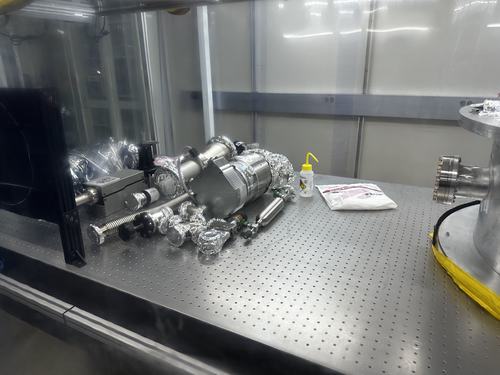

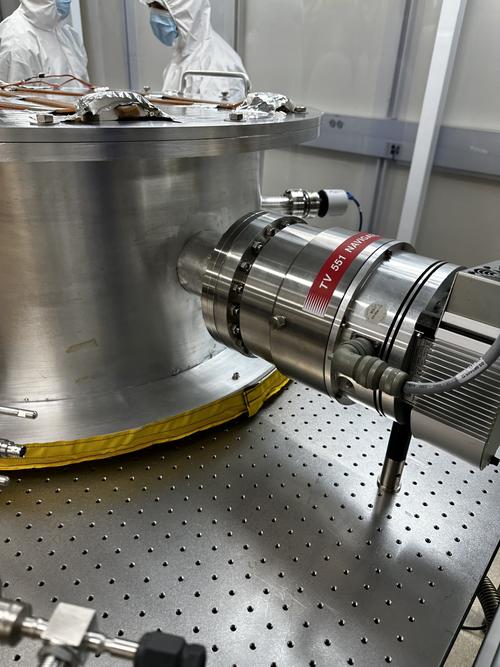

| [Luke, Aiden, Mohak , Tyler]

On Tuesday we had the silver screws for the spherical cube shortened by a quarter of an inch so that they would fit into the gate valve. We then attached the spherical cube to the vacuum chamber.

On Wednesday we finished assembling the RGA line and the main turbo pump. |

| Attachment 1: image_2024-06-19_182556383.png

|

|

| Attachment 2: image_2024-06-19_182631737.png

|

|

| Attachment 3: IMG_1710.jpg

|

|

|

423

|

Mon Aug 12 16:35:30 2024 |

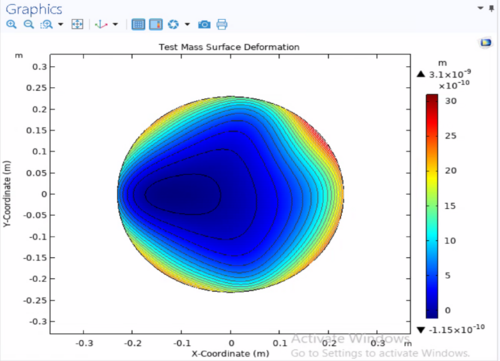

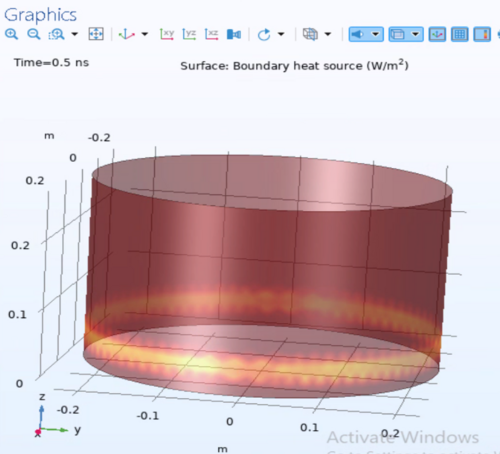

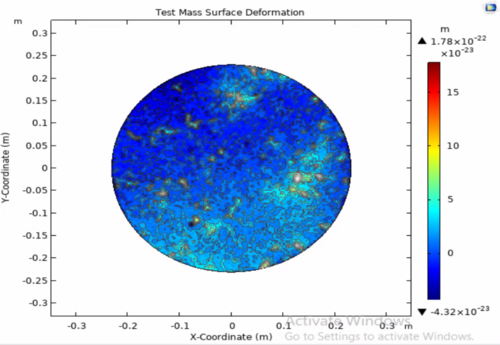

Luke | Update | | Ringheater modeling Update |

|

| Attachment 1: HR_surface_deformation.png

|

|

| Attachment 2: Irradiation_pattern_input.png

|

|

| Attachment 3: HR_surface_deformation_other.png

|

|

|

451

|

Wed Oct 2 10:31:46 2024 |

Xuesi Ma | Configuration | | Group Meeting Slides 10/2/2024 |

Group Meeting slides for Non-deterministic Heater Response.

|

| Attachment 1: Group_Meeting_10_2.pdf

|

|

|

452

|

Wed Oct 2 12:05:42 2024 |

Luke | Update | | Ringheater modeling Update |

Power point slides |

|

455

|

Wed Oct 2 14:49:59 2024 |

Liu | Update | | FROSTI ETM actuation |

| Proposed FROSTI ETM actuation on the HOM7 resonance.

Animation |

|

460

|

Wed Oct 16 14:13:31 2024 |

Liu | Update | | FROSTI with non uniform absorption scattering sources |

| Slides |

|

Draft

|

Wed Oct 23 12:33:54 2024 |

Luke | Update | | Zernike calculation update |

PowerPoint slides new

PowerPoint slides older |

|

503

|

Mon Jan 27 11:29:38 2025 |

Xuesi Ma | Update | | Heater Element Test |

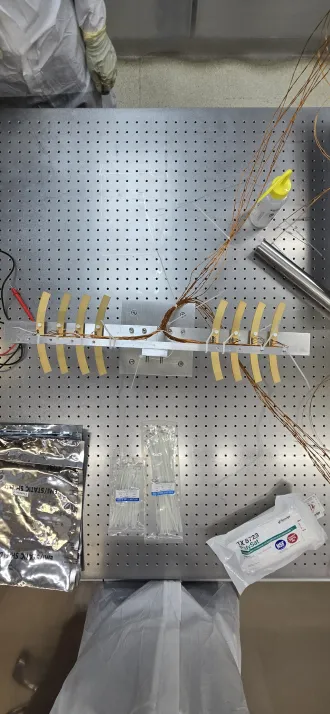

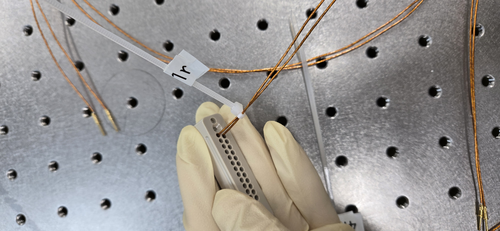

[Ma, Cece, Luke, Mary, Shane]

On Friday (Jan 24), we installed the heater elements on the stand. The heater elements are arranged from 1 to 8, oriented from right to left as shown in Attachment 1. Each wire has been labeled according to its corresponding element number and type (e.g., RTD connections, heater connections).

Note: We currently do not have enough PEEK zip ties, so standard zip ties have been used temporarily. These must be replaced with PEEK zip ties before the setup is placed in the vacuum chamber. |

| Attachment 1: 20250124_165434.png

|

|

| Attachment 2: 20250124_165342.png

|

|

| Attachment 3: 20250214_132811.jpg

|

|

|

504

|

Mon Jan 27 23:35:28 2025 |

Xuesi Ma | Update | | |

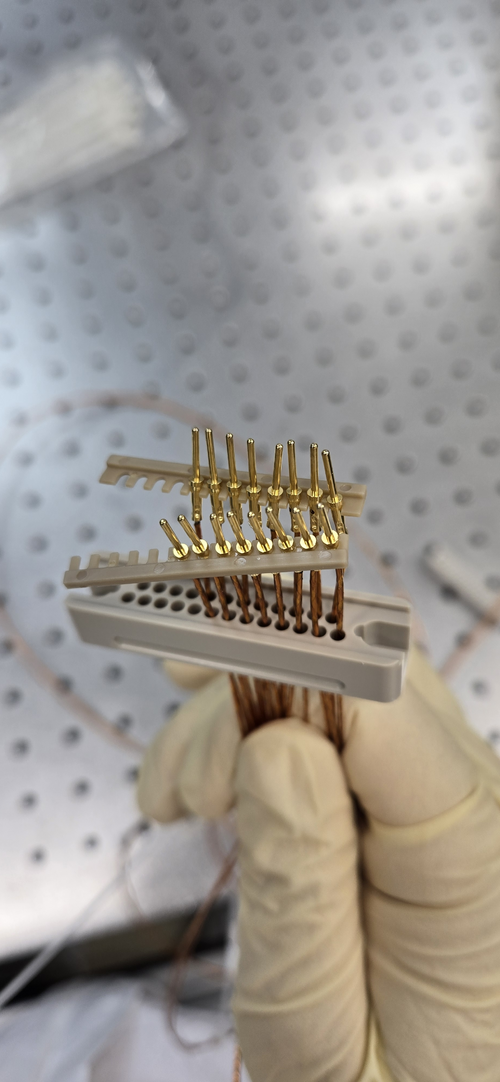

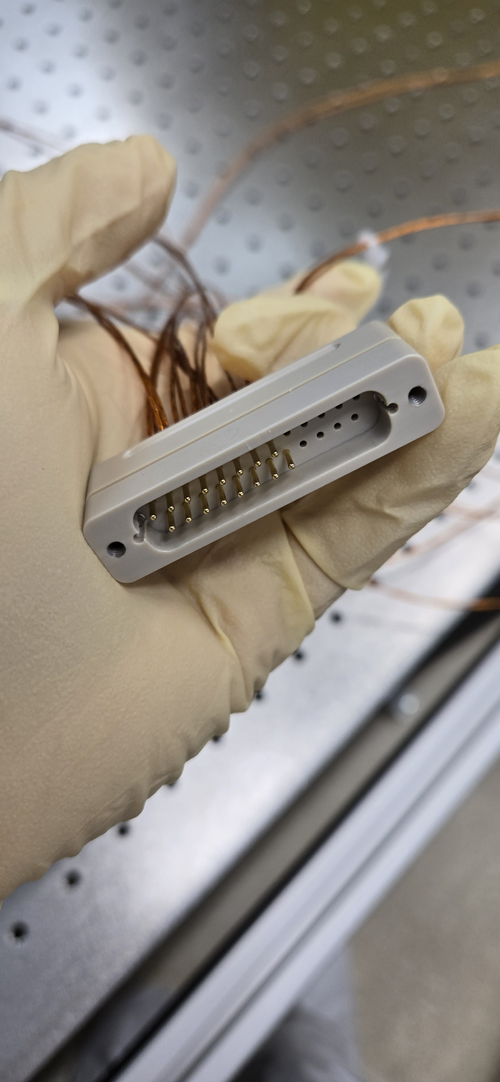

[Ma]

Installed all the pins to the peek DB 25 connectors |

| Attachment 1: 20250127_142647.jpg

|

|

| Attachment 2: 20250127_153454.jpg

|

|

| Attachment 3: 20250127_154516.jpg

|

|

|

506

|

Fri Jan 31 15:03:09 2025 |

Xuesi Ma | Update | | Heater Element Circuit Check |

|

[Ma] Wed 1/29/2025

No short circuit between heater element ✓

No short circuit to ground on any pin ✓

No short circuit between connectors ✓

| Heater Number |

Power Resistor before (Ohm) |

Power Resistor now (Ohm) |

RTD Resistor before (Ohm) |

RTD Resistor now (Ohm) |

| 1 |

73.6 |

73.1 |

81.8 |

81.3 |

| 2 |

70.4 |

69.6 |

82.1 |

81.6 |

| 3 |

71 |

70.5 |

84.5 |

84 |

| 4 |

71.5 |

71 |

80 |

79.4 |

| 5 |

70.5 |

70.2 |

81.7 |

81.2 |

| 6 |

72 |

71.6 |

79.4 |

78.7 |

| 7 |

69.2 |

69 |

78.2 |

77.5 |

| 8 |

71.1 |

70.6 |

84.2 |

83.6 |

|

|

508

|

Mon Feb 3 13:17:21 2025 |

Xuesi Ma | Update | | |

[Ma]

changed all zip ties to peek zip ties, and grouped wires together. The setup is ready to go into the chamber. |

| Attachment 1: 20250203_123153.jpg

|

|

| Attachment 2: 20250203_123213.jpg

|

|

|

514

|

Tue Feb 18 10:01:07 2025 |

Xuesi Ma | Update | | |

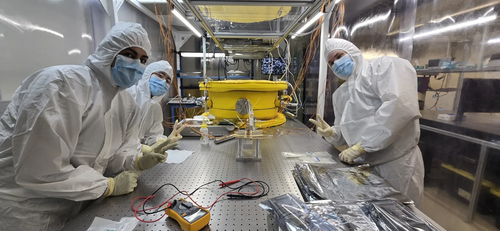

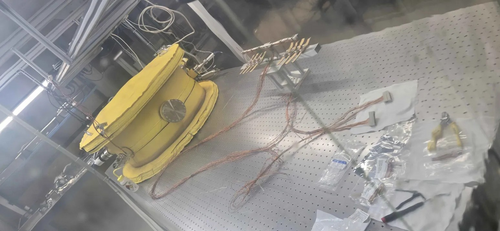

[Ma, Pooyan, Tyler]

On Friday, we connected the vacuum chamber with the Cymac. |

| Attachment 1: IMG_7916.jpeg

|

|

| Attachment 2: IMG_7915.jpeg

|

|

| Attachment 3: IMG_7917.jpeg

|

|

|

515

|

Tue Feb 18 10:02:16 2025 |

Xuesi Ma | Update | | Group Meeting Slides 2/18/2025 |

https://docs.google.com/presentation/d/1WiV2VqS0BzXNCK6VYYQ-Ty8xlHnzXatQaFbMf1-0rsY/edit?usp=sharing |

|

525

|

Tue Feb 25 10:02:32 2025 |

Xuesi Ma | Update | | |

1424039912.625576 2025/02/19 22:38:14 UTC Time start

24V 2.8A right after start all 8 elements

1424044804.902443 2025/02/19 23:59:46 UTC Time stop

24V 1.8A right before stop all 8 elements

0.1A right before start and right after stop

note: turned on briefly to check current right before stop

2/20 RGA Scan

spikes??

1424129207.857777 2025/02/20 23:26:29 UTC Time start

24V 2.9A right after start all 8 elements

1424140789.856096 2025/02/21 02:39:31 UTC Time stop

24V 1.7A right before stop all 8 elements

0.1A right before start and right after stop

2025/02/21 02:43:19 UTC

Main chamber pressure: 1.54e-8

RGA chamber pressure:5.06e-9

spikes are due to loose connection between connectors.

1424210410.173863 2025/02/21 21:59:52 UTC Time start

24V 2.9A right after start all 8 elements

1424218357.96404 2025/02/22 00:12:19 UTC Time stop

24V 1.7A right before stop all 8 elements

each elements: 0.3A (0.2A increment)(all)

0.1A right before start and right before stop

2/24 RGA Scan

1424467918.129082 2025/02/24 21:31:40 UTC Time start

12V 2A right after start all 8 elements

1424478936.635821 2025/02/25 00:35:18 UTC Time stop

12V 1.6A right before stop all 8 elements

each elements: 0.4A (0.2A increment)(all)

0.2A right before start

rise time: A(1-exp(-t/tau))+B

fall time: Aexp(-t/tau) +B |

| Attachment 1: resistance_vs_time_all_channels_all_time.pdf

|

|

| Attachment 2: temperature_vs_time_all_channels_all_time.pdf

|

|

| Attachment 3: resistance_vs_time_rise_time.pdf

|

|

| Attachment 4: resistance_vs_time_fall_time.pdf

|

|

|

529

|

Tue Mar 4 03:33:18 2025 |

Xuesi Ma | Update | | Update |

Spikes Appear Again, need to address it systematically.

Power on and off before reaching steady state ✔

At 12V, the rise and fall time of heater elements are different from 24V.

Initial guess is due to temperature in the chamber. However, it does not seem to be the case, 24V with 30c have the same hall time as 24V at lower temperature.

Attached are some graphs for rise and fall time

After a weekend of powering on, the main chamber pressure stabilized in the UHV region.

Temperature in the chamber seems also not to change. |

| Attachment 1: resistance_vs_time_all_channels_all_time.pdf

|

|

| Attachment 2: resistance_vs_time_rise_time.pdf

|

|

| Attachment 3: resistance_vs_time_fall_time.pdf

|

|

| Attachment 4: resistance_vs_time_rise_time_12V.pdf

|

|

| Attachment 5: resistance_vs_time_fall_time_12V.pdf

|

|

| Attachment 6: resistance_vs_time_fall_time_24V_30c.pdf

|

|

|

539

|

Tue Mar 11 10:43:57 2025 |

Xuesi Ma | Update | | |

Continue investigation in the spikes

Pulsed ADC with a function generator and find no spikes. Rules out ADC for causing the spikes

Loopback test that bypasses the FROSTI Chassis shows spikes (spikes happened on all channels at the same time)

Next step is to bypass the AI Chassis to find the source of the spikes |

| Attachment 1: 20250310_171936.jpg

|

|

|

544

|

Mon Mar 31 15:41:56 2025 |

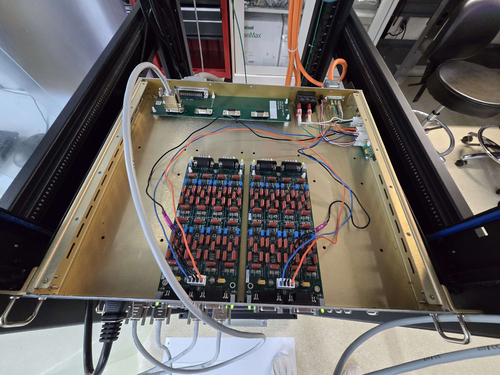

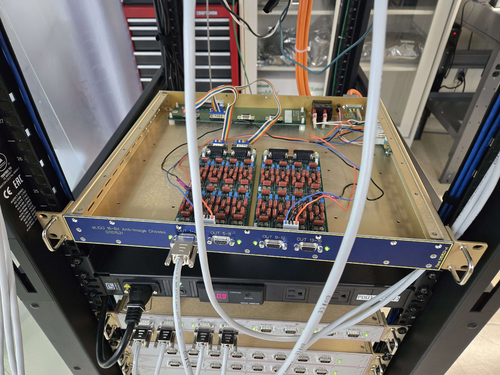

Xuesi Ma | Update | | |

The result from AI Chassis bypass test showed that the AI Chassis may be the problem. There are no spikes from DAC's direct output.

All chassis except timing chassis are turned off. Power supplies for 24V, 18V, and -18V are turned off

The AI chassis has been taken out of the rack for further inspection

Refer to:

https://dcc.ligo.org/LIGO-E2300117

https://dcc.ligo.org/cgi-bin/private/DocDB/ShowDocument?.submit=Identifier&docid=D2300124&version= |

|

545

|

Tue Apr 1 11:47:08 2025 |

Liu | Update | | |

|

| Attachment 1: Thermal_state_decoder_update.pdf

|

|

|

547

|

Mon Apr 7 13:28:49 2025 |

Xuesi Ma | Update | | |

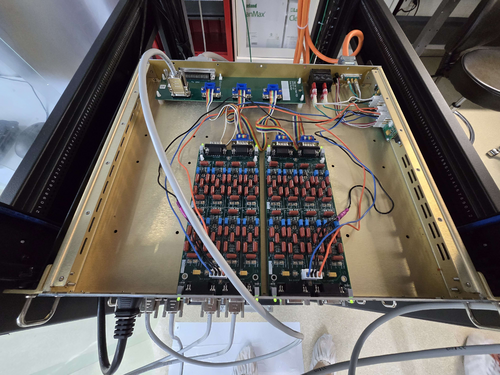

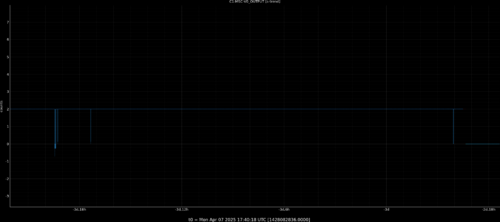

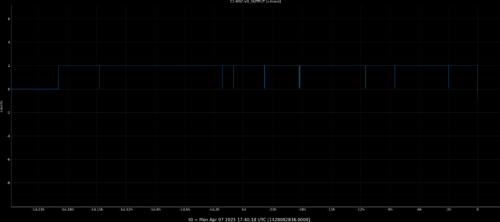

Test 1: Adapter Board Connected to Filter Board

- Setup: AI Chassis is powered on. Signal is measured directly from the adapter board. All other ports on the adapter board are connected to the filter board.

- Observation: Two distinct spikes observed at the beginning of the measurement.

Test 2: Adapter Board Disconnected from Filter Board

- Setup: AI Chassis remains powered on. Signal is again measured directly from the adapter board. This time, the remaining ports on the adapter board are not connected to the filter board.

- Observation: Multiple spikes observed, distributed evenly across the entire measurement.

Test 3: Isolation Test with Spare Adapter Board (ongoing)

- Setup: Suspecting the original adapter board may be faulty, a spare adapter board is used for comparison. Signal is measured directly from this spare board.

-

Update, 04/08/25, Tue 17:30

Took the old adapter board out of the AI chassis and and used it to connect DAC to AA chassis. If no spikes are seen, it means that the glitches are not originating from this board.

Also checked al the previous spikes using the raw data (65536 Hz sample rate). The duration of the glitches are ~1 second, despite the previous guess that they are happening in the Milli-second scale.

|

| Attachment 1: 20250403_151946.jpg

|

|

| Attachment 2: ELOG_Spike_adapter_filter_on.png

|

|

| Attachment 3: 20250404_143624.jpg

|

|

| Attachment 4: ELOG_Spike_adapter_isolate.png

|

|

| Attachment 5: 20250407_105846.jpg

|

|

|

553

|

Tue Apr 15 11:13:43 2025 |

Xuesi Ma | Update | | |

Test 4: AI Chassis ground isolation

- Setup: AI Chassis isolated from the ground with readout directly connected to adapter board

- Observation: No spike observed.

Test 5: Ribbon cable check

- Setup: AI Chassis remains isolated from the ground. The signal is measured after the ribbon cable. (Attachment 3)

- Observation: No spike observed.

Test 6: Single ground connection check

- Setup: AI chassis powered on but remains isolated from the frame. The signal is measured from the output of the AI Chassis. (Attachment 1 ,2)

-

- Observation: No spike observed.

|

| Attachment 1: 20250414_120428.jpg

|

|

| Attachment 2: 20250414_120423.jpg

|

|

| Attachment 3: 20250411_163105.jpg

|

|

|

559

|

Tue Apr 22 12:08:46 2025 |

Xuesi Ma | Update | | |

Test 7: Reconnect ribbon cables

- Setup: Reconnect all the ribbon cables, and turned on the AI Chassis while isolated rack

- Observation: No spike observed.

Test 8: Reconnect to rack

- Setup: Reconnect the AI Chassis to the rack.

- Observation: No spike observed.

Test 9: Restore to original position.

- Setup: CLose up the AI Chassis, and put it back to its original location.

-

- Observation: No spike observed.

|

| Attachment 1: 20250415_161755.jpg

|

|

| Attachment 2: 20250416_174640.jpg

|

|

| Attachment 3: 20250422_105614.jpg

|

|

|

572

|

Tue May 6 13:19:31 2025 |

Xuesi Ma | Update | | |

|

| Attachment 1: resistance_vs_time_RV_rise_time_24.pdf

|

|

| Attachment 2: resistance_vs_time_all_channels_all_time_RV.pdf

|

|

|

576

|

Tue May 13 12:35:01 2025 |

Xuesi Ma | Update | | |

|

| Attachment 1: resistance_vs_voltage_all.pdf

|

|

| Attachment 2: resistance_vs_voltage_overlay.pdf

|

|

| Attachment 3: resistance_vs_time_all_channels_all_time_RV.pdf

|

|