| ID |

Date |

Author |

Type |

Category |

Subject |

|

335

|

Thu Feb 22 21:48:16 2024 |

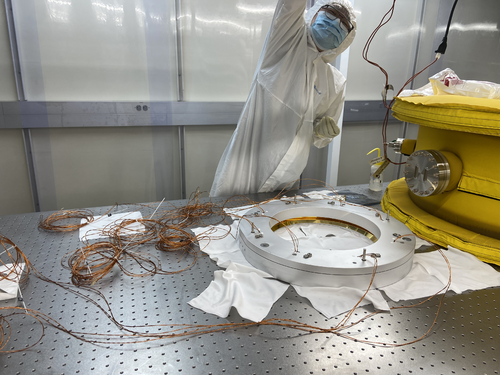

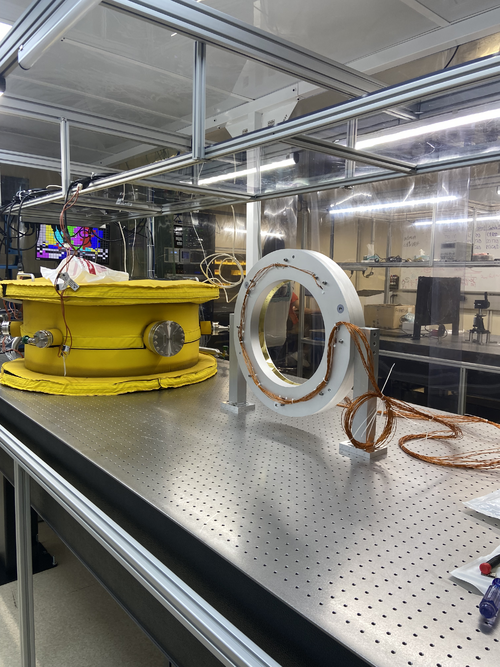

Jon | Update | VAC | Vacuum vent for RGA testing of reflector |

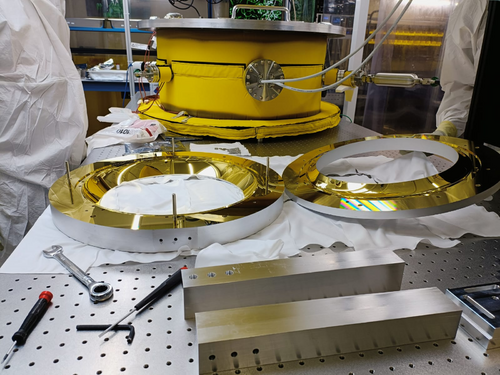

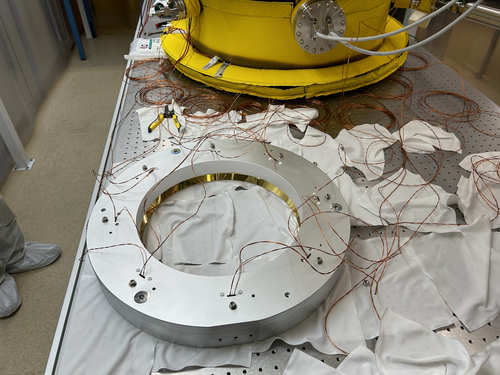

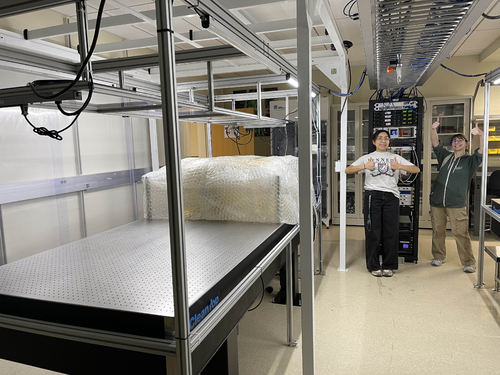

[Jon, Tyler, Luke, Aiden]

Summary

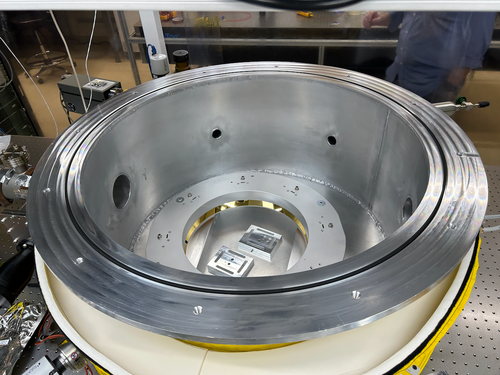

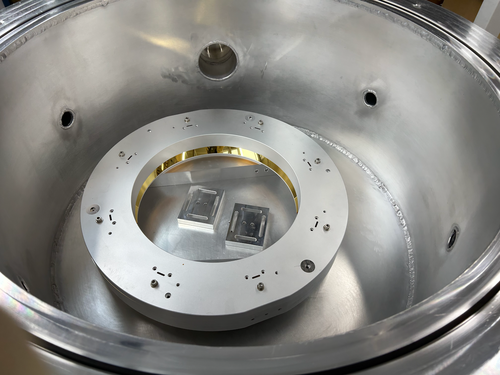

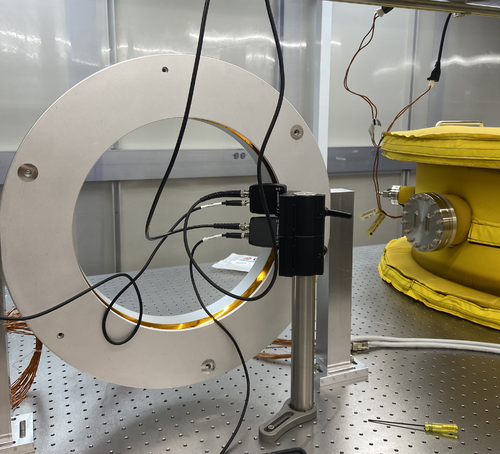

Following Wednesday's cleanroom cleaning [333], we proceeded to vent the vacuum chamber, remove the heater elements and their mount structure, and install the FROSTI reflectors. The reflectors are the final components to undergo RGA testing before the FROSTI prototype can be assembled. After installing the reflectors, we pumped the chamber back down and initiated a 48-hour 125 C bake.

Vacuum Vent

At ~1:00 pm, we shut off power to all eight of the FROSTI heater elements. Prior to shutoff, all were operating in vacuum at roughly 300 C. We then waited approximately 30 minutes for the elements' temperatures to fall below 50 C.

At this point, we isolated the RGA volume from the main volume by closing both gate valves, leaving the RGA volume to continue to be pumped through the bypass line. We then backfilled the main volume via the needle valve connected to one of the 2.75" ports. Once the pressures had equalized, we removed the chamber lid via our usual procedure (requiring only a small amount of flathead-screwdriver prying) and extracted the heater element assembly.

Reflector Assembly

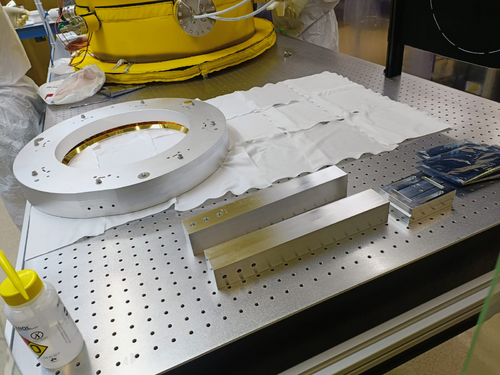

We then removed the FROSTI reflectors from their protective packaging (for the very first time) on the cleanroom tabletop. We tested the fit of the Macor and stainless steel hardware in the reflectors' tapped holes. The Macor standoffs and bolts appear to fit perfectly. However, the 1/4-20 tapped holes for joining the two reflector halves are too shallow by ~1/4". As a temporary fix, we used some on-hand stainless steel washers (which had already been cleaned and baked) to securely fasten the two halves together. In the final assembly we will replace these with slightly shorter 1/4-20 vented bolts.

Pumpdown and Bake

The two fastened reflector halves were placed inside the chamber, sitting on top of the two mounting legs (see attached photos). We then reinstalled the lid. In order to rough the main volume, we isolated the RGA volume from the pumpline (by closing the bypass line valve), shut down the pumps, and then backfilled the pumpline via the manual vent valve on the turbo pump.

Once the pressures had equalized, we opened the 6" gate valve separating the pumpline from the main volume and powered on the roughing pump. Once the main volume pressure fell below 0.5 Torr, we powered on the turbo pump as well. The main volume pressure reached 5e-6 Torr within ~30 minutes, consistent with previous experience, and was continuing to slowly fall.

Lastly, we initiated a 125 C bake-out of the entire system following our usual procedure. We plan to run this bake for 48 hours (i.e., through the end of the day Friday). |

| Attachment 1: IMG_0938.png

|

|

| Attachment 2: IMG_0939.png

|

|

|

339

|

Sat Feb 24 08:53:38 2024 |

Jon | Infrastructure | Computers | Matlab upgraded to 2023b on Chimay |

| I upgraded Matlab on chimay to the latest stable release, 2023b. From some quick tests, it appears to be in working order. Let me know of any issues. |

|

341

|

Mon Feb 26 21:23:27 2024 |

Jon | Update | TCS | FROSTI Assembly - Day 1 |

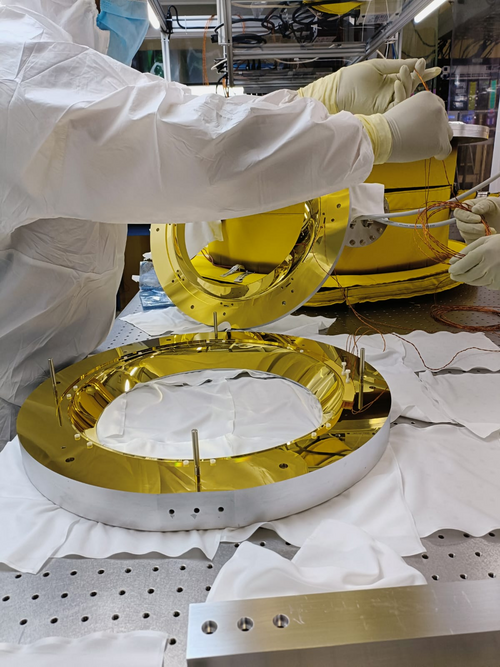

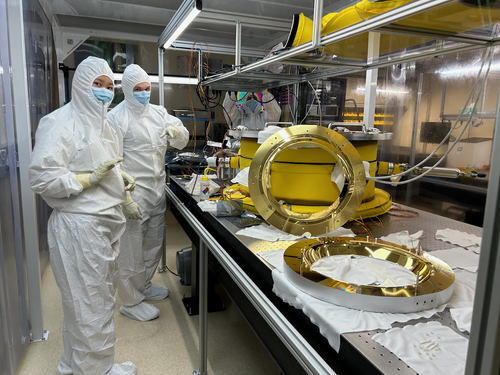

| [Jon, Tyler, Luis, Luke, Mohak, Cynthia, Michael, Aiden]

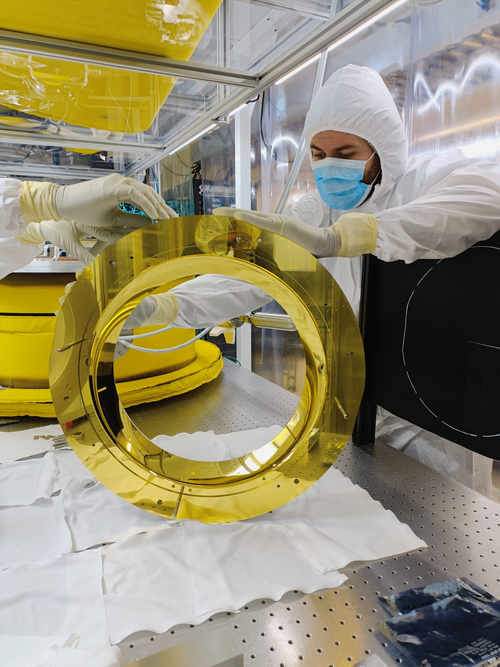

FROSTI assembly began today. After a final set of RGA scans were taken, the vacuum chamber was vented and the reflectors were removed. The chamber was then resealed and pumped down again.

Today we completed the installation of the Macor hardware and heater elements between the two reflector halves. Tomorrow we will route, bundle, and terminate the power and sensor cables. |

| Attachment 1: IMG-20240226-WA0008.jpg

|

|

| Attachment 2: IMG-20240226-WA0006.jpg

|

|

| Attachment 3: IMG-20240226-WA0011.jpg

|

|

| Attachment 4: IMG-20240226-WA0010.jpg

|

|

| Attachment 5: IMG-20240226-WA0012.jpg

|

|

| Attachment 6: IMG_0944.png

|

|

| Attachment 7: IMG_0946.png

|

|

|

379

|

Thu Jun 20 18:01:11 2024 |

Jon | Infrastructure | Computers | New workstation ws3 in 1129 |

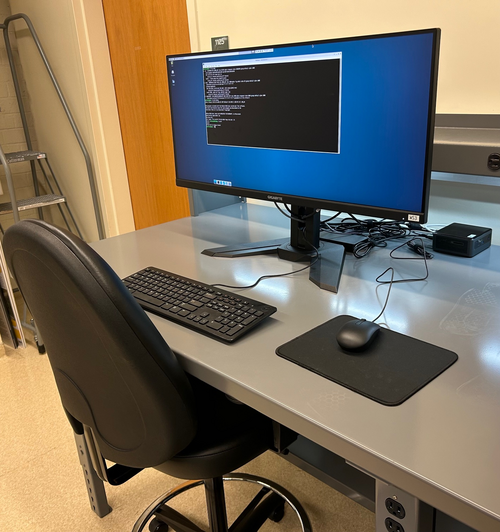

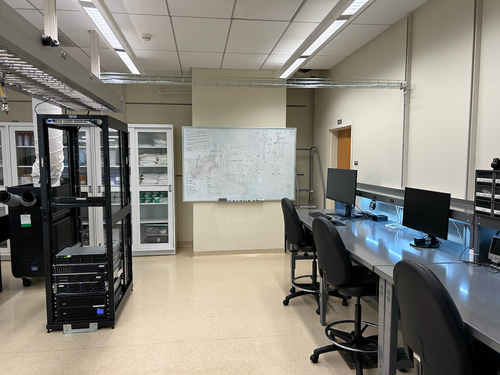

| I have repurposed a spare Intel NUC to serve as the first of two planned workstations in 1129. Today I set it up with a fresh installation of Debian 12.5, assigned it the static IP address 192.168.1.15, and installed the LIGO CDS workstation packages. It is assigned the host name ws3.

Temporarily, the mouse is borrowed from ws1 in 1119. We need to order another mouse as well as a 25-ft Ethernet cable for connecting the workstation to the 1129 switch, via the ceiling. |

|

385

|

Wed Jun 26 15:33:41 2024 |

Jon | Infrastructure | Computers | New workstation ws3 in 1129 |

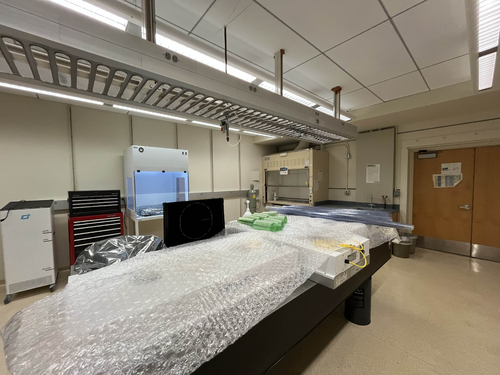

Set-up of the first CDS workstation for 1129, ws3, is complete and the machine is ready for use. The login credentials are the same as the other lab machines.

All that now remains is to install a permanent cable tray for running the new Ethernet cables between the electronics rack and bench (they are currently dangling from the suspended lights).

| Quote: |

| I have repurposed a spare Intel NUC to serve as the first of two planned workstations in 1129. Today I set it up with a fresh installation of Debian 12.5, assigned it the static IP address 192.168.1.15, and installed the LIGO CDS workstation packages. It is assigned the host name ws3.

Temporarily, the mouse is borrowed from ws1 in 1119. We need to order another mouse as well as a 25-ft Ethernet cable for connecting the workstation to the 1129 switch, via the ceiling. |

|

| Attachment 1: IMG_1368.jpg

|

|

|

402

|

Thu Jul 11 21:01:37 2024 |

Jon | Infrastructure | General | Cable tray installed in 1129 |

| Today I installed a 10' cable tray in 1129, for permanently routing Ethernet lines to the workstations. It is securely bolted to C-channels in the side wall and in the center cable tray. |

| Attachment 1: IMG_1395.png

|

|

| Attachment 2: IMG_1396.png

|

|

|

412

|

Fri Jul 26 17:25:42 2024 |

Jon | Infrastructure | Computers | New workstation ws4 installed in 1129 |

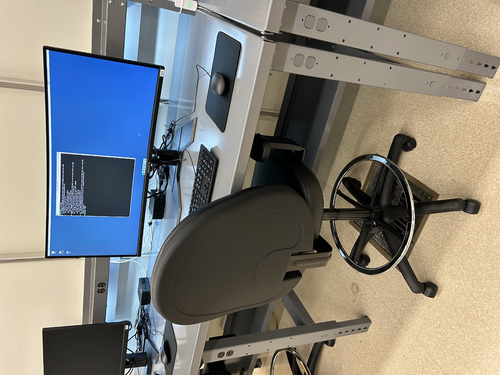

Today I installed the second desktop workstation in 1129. The new machine is an Intel NUC13ANHi5, with a 12-Core Intel i5-1340P CPU, 32GB DDR4 RAM, and a 1TB SSD.

I loaded it with a fresh installation of Debian 12 and installed the LIGO CDS workstation (control room) tools. It is assigned the hostname ws4 and and the static IP address 192.168.1.19 on the local lab network. Like the other CDS workstations, there is just one user account accessible with the usual credentials.

The machine is fully set up and ready for use. |

| Attachment 1: ws4.jpg

|

|

|

418

|

Tue Jul 30 07:42:47 2024 |

Jon | Infrastructure | General | Cable tray installed in 1119 |

| Yesterday I installed another 5' cable tray in 1119, for permanently routing Ethernet lines to the L-bench. It is securely bolted to the top of the electronics rack, on one end, and to the top of the glass-door storage cabinet, on the other. This eliminates the need for the cable ramp which previously sat behind the rack. |

| Attachment 1: cable_tray_1119.jpg

|

|

|

670

|

Thu Jan 22 10:10:31 2026 |

Jon | Infrastructure | General | Lab floor plans |

| Attached are the starting and final floor plans for the February 2026 expansion into the Physics 1125 lab. |

| Attachment 1: Pre-Feb-2026.png

|

|

| Attachment 2: Post-Feb-2026.png

|

|

|

676

|

Thu Feb 5 11:42:47 2026 |

Jon | Infrastructure | General | Lab floor plans |

[Audrey, Cece, Jon, Ma, Mary, Michael, Pooyan, Tyler, Shane]

We have completed the preliminary reorganization of our Physics 1119 lab space. This includes:

- Moving all cabinets to their final positions

- Clearing out all equipment from the cleanroom in prep for HVAC work, and storing them in either the HEPA cabinet or double-bagging in regular storage.

- Moving all non-essential equipment into other lab spaces.

- Wrapping vacuum system and VLC for protection

- Removing all ceiling tiles and fans from the ceiling of the cleanroom

- Moving the cleanroom frame towards the front of the room.

Prepping the new clean-and-bake station in 1125 will begin within the next week, along with the construction of the stainless steel table planned to be put into the cleanroom.

| Quote: |

| Attached are the starting and final floor plans for the February 2026 expansion into the Physics 1125 lab. |

|

| Attachment 1: image.jpg

|

|

| Attachment 2: image_1.jpg

|

|

| Attachment 3: image_3.jpg

|

|

|

26

|

Fri Feb 10 16:34:45 2023 |

Huy Tuong Cao | Infrastructure | Clean & Bake | Nitrogen gas tank ready to use |

| Cao,

Today I fixed the final bit related to the nitrogen gas tank, which is to apply sealing tape to M-NPT connector of the hose to prevent

leakage (file: AirGunSealed.jpg)

After application of the tape, no audible leak can be heard from connection between the hose and the air gun.

The general operating procedure for the gas tank is as following:

- Turn the regulator (blue handle) anti-clockwise still it's loose

- Turn the valve on nitrogen as tank anti-clockwise, immediately the RHS meter of the regulator would jump to approx 2000 psi. This is the standard pressure for high pressure gas tank

- Turn the regulator clock-wise slowly until the pressure one the LHS meter face reads approx 60 psi. This is sufficient for drying parts with. At this point, the flow pressure still should register zero

- Press the trigger on the air gun, a high pressure air flow should come out and the flow meter should increase

- When finished, close the gas tank valve, turn the regulator anti-clockwise, then press the air gun trigger to release gas left in the hose/gun

|

| Attachment 1: AirGunSealed.jpg

|

|

|

359

|

Mon Apr 8 14:57:41 2024 |

Cynthia, Pooyan | Update | Interferometer Simulations | performed cavity scans for O4 O5, and coupled cavity |

|

| Attachment 1: LIGO_update_week1.pdf

|

|

|

343

|

Tue Feb 27 09:06:29 2024 |

Cynthia | Update | Interferometer Simulations | cavity scan with higher order input laser |

| I performed a few cavity scan with the inputing laser with a different mode (not pure 00). For each laser I included a graph for just plotting the order with highest power (for example 1st order laser input the first plot only scanned for 1st order in that cavity), and I have also included a graph scanning for order 1-10. |

| Attachment 1: ligoPre_2_27.pdf

|

|

|

363

|

Mon Apr 22 15:06:33 2024 |

Cynthia | Update | Interferometer Simulations | cavity scan update |

| [Cynthia,Pooyan]

Completed some simulations injecting 0-10th order modes. Some graphs will be used for the poster after some further titles, axis, and range adjustments. |

| Attachment 1: LIGO_4_22.pdf

|

|

|

381

|

Mon Jun 24 14:28:51 2024 |

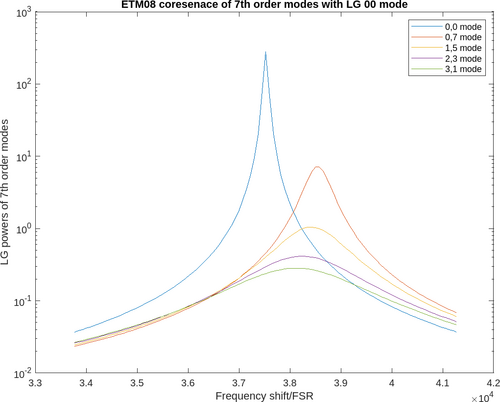

Cynthia | Update | Interferometer Simulations | SIS cavity with thermal effect |

| tried to run a cavity scan with thermal deformation and ring heater for ITM04 ETM08 (aLIGO mirrors). Not sure about the accuracy of the graph as there is some commands that still need to verified. |

| Attachment 1: ETM08thermal.png

|

|

|

392

|

Mon Jul 1 15:19:42 2024 |

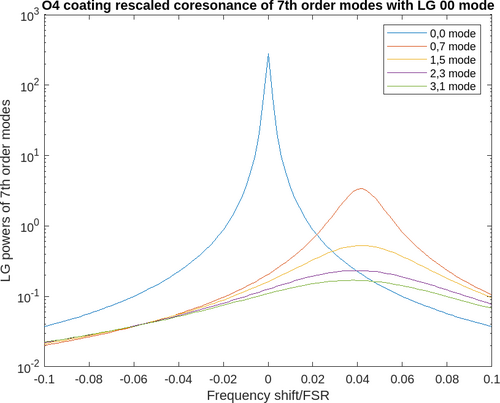

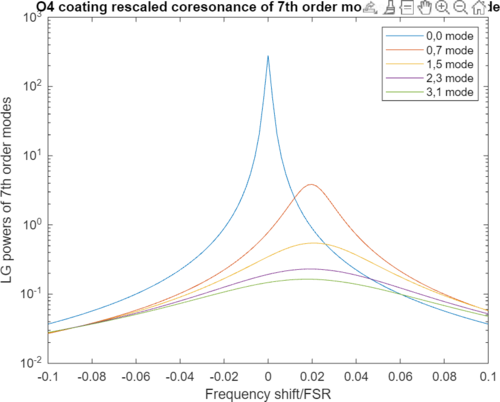

Cynthia | Update | Interferometer Simulations | O4 and O5 mirror cavity scans with thermal effect |

|

| Attachment 1: cavityScan_07_01.pdf

|

|

|

408

|

Mon Jul 15 15:44:52 2024 |

Cynthia | Update | Interferometer Simulations | performed cavity scans with thermal effects and ring heater |

|

| Attachment 1: cavity_scan_07_15.pdf

|

|

|

424

|

Mon Aug 12 17:09:04 2024 |

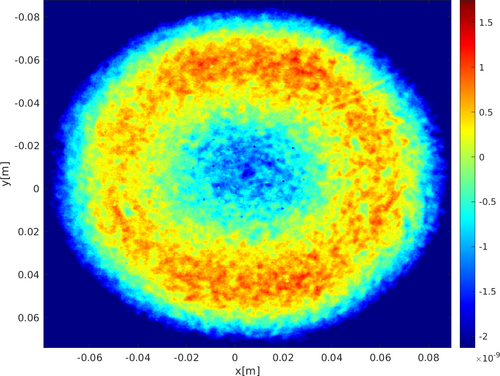

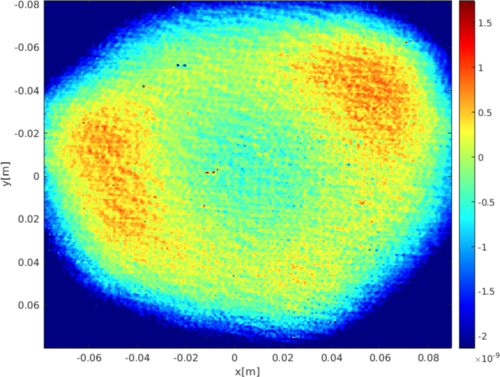

Cynthia | Update | Interferometer Simulations | O4 vs O5 cavity scans with ITM plume guess or ETM |

| So far the proposed solution for what to use for O5 ITM mirror for SIS simulations is either the plume guess file or using the O5 ETM mirror for ITM. I had ran a cavity scan for both of these possibilities and it seems like the results produced are fairly different. The next step is most likely moving on to adding the Frosti effects including both of the proposed possibilities, and before this, a few confirmations and verifications are needed using similar previous studies to make sure my code produce the right result. |

| Attachment 1: O5_plots_and_tables.pdf

|

|

| Attachment 2: O4_plots_and_tables.pdf

|

|

| Attachment 3: ETM12mapO5.png

|

|

| Attachment 4: Screenshot_2024-08-12_at_5.05.31_PM.png

|

|

|

428

|

Mon Aug 26 14:42:04 2024 |

Cynthia | Update | Interferometer Simulations | current status on cavity scan with effects of FROSTI |

| I used the code and arm cavity model used for previous O5 study on mirrors and HOM (the pdf of the study and the result can be found at https://dcc.ligo.org/LIGO-G2100878), but it seems like the result I obtained is different from the study result. Since my cavity scans codes have a large portion of it relying on this code, I will have to go over the study result and the code to make sure there is no issue with that code itself first. There are also some other updates or issued encountered when I tried to plot the mirror maps with effects of FROSTI. |

| Attachment 1: LIGO_updates_8_26.pdf

|

|

|

443

|

Mon Sep 16 15:18:59 2024 |

Cynthia | Update | Interferometer Simulations | a breakdown of FROSTI and thermal effects and the resulting cavity scan |

|

| Attachment 1: ligo_update_9_16_(1).pdf

|

.png)

|

|

446

|

Mon Sep 23 15:00:41 2024 |

Cynthia | Update | Interferometer Simulations | corrections on assumption for O5 coating |

| The document recording ETM07 and ETM08 coating (T2300093) was discussed:

the current plume files are not necessarily correct in a way that LIGO lab have tried to add it on uncoated ETM such as ETM07 and it does not match what the coated ETM07 would look like.

the plume should be added on top of the uncoated ETM instead of assuming an ideal ETM. According to Garilynn, the imperfection on uncoated ETM matters.

So far the possible ETM data used for O5, ETM 11,14,19, and 20 are all uncoated, and different ways could be used to predict the plume, including the plume data on LIGO dcc or subtract the uncoated data from the coated for O4 ETM and use that as another guessed plume. |

| Attachment 1: Uncoated_S1_ETM07-v2.pdf

|

|

|

587

|

Tue Jun 3 12:16:13 2025 |

Cynthia | Update | Interferometer Simulations | Point absorber simulation on radially averaged profile |

|

| Attachment 1: update_6_3.pdf

|

|

|

679

|

Thu Feb 5 13:34:13 2026 |

Cynthia | Update | Interferometer Simulations | Point absorber + miscentering simulation |

|

| Attachment 1: update2_5_(3).pdf

|

.png)

|

|

361

|

Mon Apr 15 15:25:10 2024 |

Cynthia | Update | Interferometer Simulations | progress on simulation so far |

|

| Attachment 1: LIGO_update_week3_(2).pdf

|

.png)

|

|

374

|

Mon Jun 3 14:59:44 2024 |

Cynthia | Update | Interferometer Simulations | Created cavity scan with LG modes |

|

| Attachment 1: ligo_update_6_3.pdf

|

|

|

426

|

Mon Aug 19 07:11:55 2024 |

Cynthia | Update | Interferometer Simulations | cavity scans with FROSTI effects |

|

| Attachment 1: LIGO_update_8_19.pdf

|

|

|

454

|

Wed Oct 2 13:38:00 2024 |

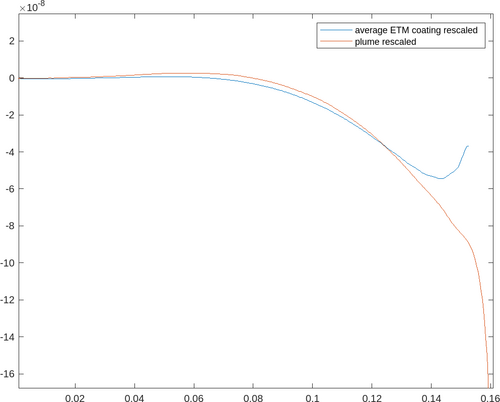

Cynthia | Update | Interferometer Simulations | cavity scan with averaged O4 ETM coating as plume |

|

| Attachment 1: O5plumevsCoating.png

|

|

| Attachment 2: O5CoatAvgpt5.png

|

|

| Attachment 3: O5AVgcoatingFROSTIpt5.PNG

|

|

|

526

|

Tue Feb 25 10:56:25 2025 |

Cynthia | Update | Interferometer Simulations | mirror coating added for simulation rerun |

| I have tried to rerun the simulation on finesse after adding the mirror coating. The result has a large fluctuation in required input power vs arm power that is concerning. I am currently working on potentially resolve this issue and get a reasonable graph before I proceed to optimizing the thermal maps. |

| Attachment 1: updats_(3).pdf

|

.png)

|

|

530

|

Tue Mar 4 10:18:43 2025 |

Cynthia | Update | Interferometer Simulations | attempted to remove curvature and tilt for the coating |

|

| Attachment 1: 3_4_updates.pdf

|

|

|

540

|

Tue Mar 11 11:28:52 2025 |

Cynthia | Update | Interferometer Simulations | flattening mirror to study power discrepency |

|

| Attachment 1: updates_3_11_(1).pdf

|

.png)

|

|

554

|

Tue Apr 15 11:37:17 2025 |

Cynthia | Update | Interferometer Simulations | Finishing up mirror coating map step |

|

| Attachment 1: updates_4_15_2025.pdf

|

|

|

635

|

Tue Aug 26 12:45:41 2025 |

Christina, Ma, Tyler | Update | CDS | RIN Update |

| Slides |

|

600

|

Fri Jun 27 15:38:22 2025 |

Christina | Update | TCS | FROSTI Reconstruction |

[Tyler, Ma, Christina, Luke]

We threaded the wiring of the heater elements through the reflective surfaces and were able to attach each piece with the Macor spacers and connect both sides. We used the guide rails and screws to ensure proper alignment. The only necessary step left is to add the additional external screws for the reconstruction. |

| Attachment 1: IMG_4009.png

|

|

|

601

|

Tue Jul 1 11:04:00 2025 |

Christina | Update | TCS | FROSTI Reconstruction II |

[Ma, Tyler, Christina]

Finished external reconstruction of the FROSTI by installing all the pins to the 2 DB 25 connectors. To ensure everything was operating correctly, we did electrical testing by testing continuity and by checking each of the heater elements' RTD and power resistance values and comparing them to what was tabulated in January. Additionally, we organized the wires and added the stands. |

| Attachment 1: IMG_4042.png

|

|

|

604

|

Mon Jul 7 16:39:18 2025 |

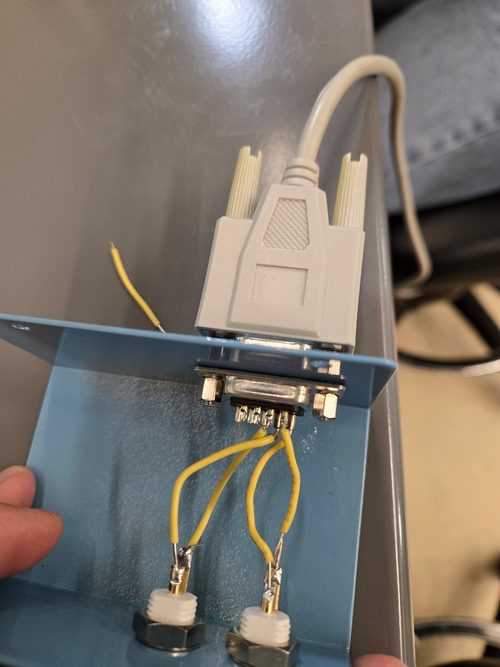

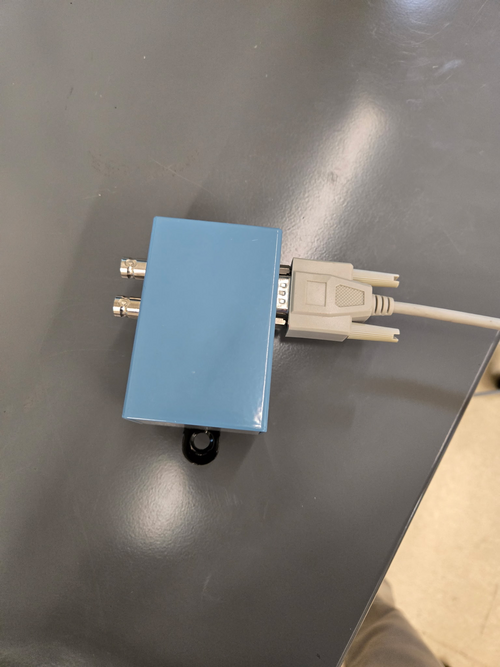

Christina | Update | TCS | Pomona Box Drawings |

Below are the drawings for the pomona box modifications |

| Attachment 1: pbdwg1.PDF

|

|

| Attachment 2: pbdwg2.pdf

|

|

|

608

|

Thu Jul 10 16:41:18 2025 |

Christina | Update | TCS | |

[Christina, Ma, Tyler]

Pomona Box completed and is now on the server rack in 1119. Additionally, the photodetectors were connected to the box and set up in front of the heater elements. |

| Attachment 1: 2994921113032912040.JPG

|

|

| Attachment 2: 4717009101108174053.JPG

|

|

| Attachment 3: 5782646701589802125.JPG

|

|

|

611

|

Tue Jul 15 10:40:23 2025 |

Christina | Update | TCS | |

[Christina, Ma, Tyler]

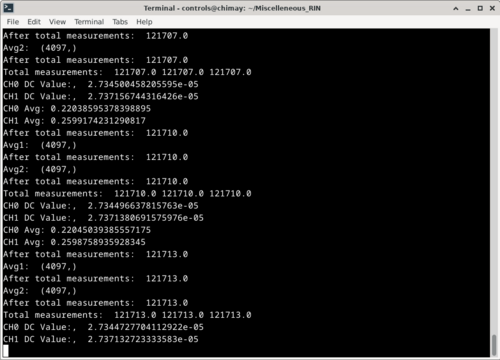

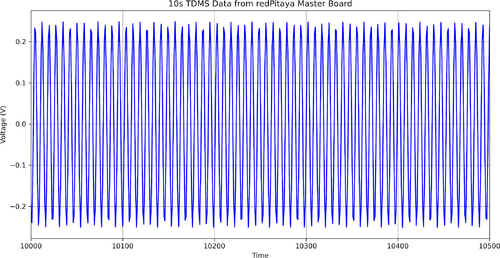

Yesterday, Ma and I started taking data for the PSD/CSD measurements while the photodetectors and one of the heater elements are on (8) and are using the Red Pitaya to compare it to the data we took for the same measurements on the CyMAC. It will be finished Wednesday morning, and then we plan on starting to take additional recordings in order to conduct the same type of comparison for the dark noise measurements. |

| Attachment 1: rpon.png

|

|

|

614

|

Tue Jul 15 13:13:48 2025 |

Christina | Update | TCS | Photodetector optical post assembly |

|

| Attachment 1: pdreassembly.png

|

|

|

615

|

Tue Jul 22 12:20:29 2025 |

Christina | Update | TCS | |

[Ma, Christina, Tyler]

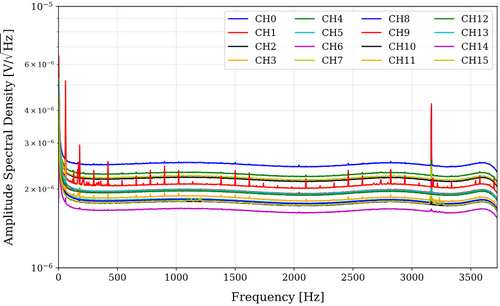

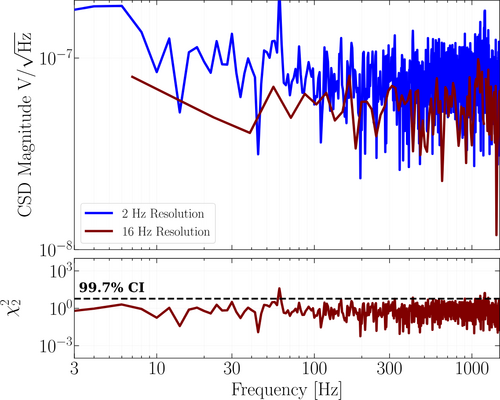

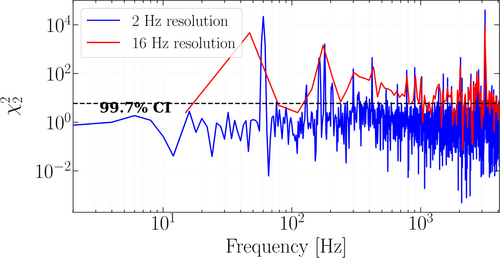

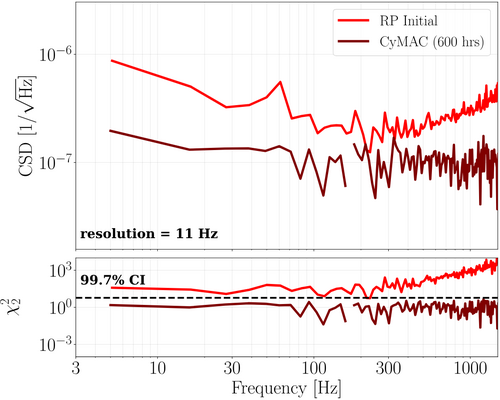

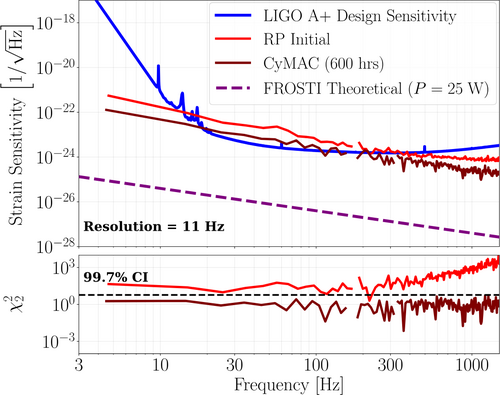

Figure 1 shows the following PSDs for channels 0-15 from the 14 hour test. Figure 2 shows the reduced chi squared and CSD plots for both the 2 Hz and 16 Hz resolutions.

|

| Attachment 1: PSDch0-15.png

|

|

| Attachment 2: CSD2hz_16hz.png

|

|

|

619

|

Tue Jul 29 12:30:00 2025 |

Christina | Update | TCS | 260 hour ADC update |

[Ma, Christina, Tyler]

ADC CyMAC 260 hr, 8192Hz sampling rate channels V3 and Vref6 |

| Attachment 1: CSD_06_28_25_270hr.png

|

|

|

624

|

Mon Aug 11 22:19:50 2025 |

Christina | Update | TCS | Red Pitaya Data Streaming |

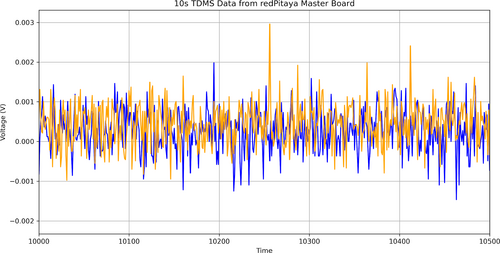

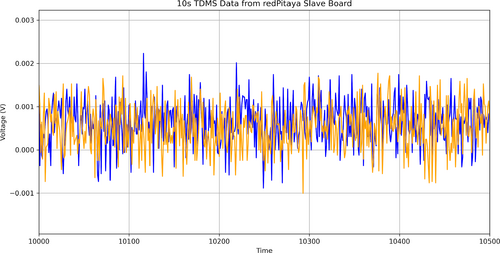

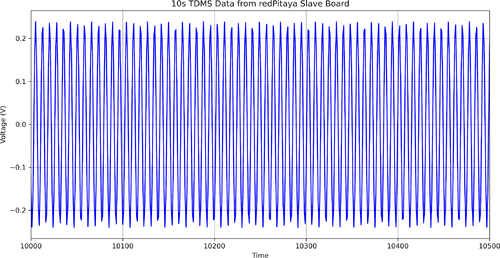

[Ma, Tyler, Christina]

This past week, we were able to set up the data streaming for continuous acquisition to the PCs, and can conduct the initial tests now. We were able to do this by:

- Installing the correct OS ecosystems to each Red Pitaya

- Installing the terminal streaming client

- Debugging formatting and file saving issues by saving the data in a TDMS file on the host PC.

We have started streaming the ADC data on Monday from both boards for 2 days, which are currently in the clean room. Below are the ADC tests we performed before starting the 2-day run. (Time in ms) |

| Attachment 1: 3.png

|

|

| Attachment 2: 3-1.png

|

|

|

629

|

Tue Aug 12 13:46:56 2025 |

Christina | Update | | |

|

| Attachment 1: 3.png

|

|

| Attachment 2: 3-1.png

|

|

|

631

|

Tue Aug 19 12:08:40 2025 |

Christina | Update | TCS | RP Initial vs CyMAC Plot Comparisons |

| [Tyler, Ma, Christina]

These are the frequency averaged and veto binned plots for the initial Red Pitaya and CyMAC systems. |

| Attachment 1: 11hzCSD.png

|

|

| Attachment 2: 11hzstrain.png

|

|

|

173

|

Thu Jul 27 10:18:43 2023 |

Celeste | Update | TCS | Graphical Updates to HOM RH Modification |

| Attached are updated graphs of the irradiance distribution from the 1/8th ring heater units (extruded and reduced in length). |

| Attachment 1: HOM_RH_1_8_Unit_Modification_Graphs.pdf

|

|

|

180

|

Fri Jul 28 17:45:45 2023 |

Celeste | Update | TCS | Graphical Updates to HOM RH Modification, Friday 7/28 |

| Updated 1/8th Heater simulation modification graphs. Slides 7, 10, 16-19 are new additions. |

| Attachment 1: HOM_RH_Simulation_Progress.pdf

|

|

|

187

|

Tue Aug 1 16:22:35 2023 |

Celeste | Update | TCS | Graphical Updates to HOM RH Modification, Tuesday 8/1 |

| Slides 20-33 are newly added (data/graphs from parameter sweep feature-1/8th heater unit length varied from 10% of original to 100% of original). |

| Attachment 1: HOM_RH_Simulation_Progress_80123.pdf

|

|

|

200

|

Thu Aug 10 14:13:38 2023 |

Celeste | Update | TCS | 8/10/23, Simulation Graphical Progress |

|

| Attachment 1: Simulation_Progress__8_10_23.pdf

|

|

|

204

|

Fri Aug 11 10:57:20 2023 |

Celeste | Update | TCS | 8/11/23 Simulation Progress |

|

| Attachment 1: Simulation_Progress__1_32nd_Model_(1).pdf

|

.png)

|

|

209

|

Tue Aug 15 16:10:06 2023 |

Celeste | Update | TCS | 8/15/2023 Simulation Progress |

|

| Attachment 1: Simulation_Progress__1_32nd_Model_(2).pdf

|

.png)

|

|

586

|

Tue Jun 3 11:54:06 2025 |

Cece Ochoa | Update | | CE Cavity Design Update |

| Update on the design for the CE Cavity Mirrors |

| Attachment 1: CE_Arm_Cavity_.pdf

|

|