| ID |

Date |

Author |

Type |

Category |

Subject |

|

373

|

Mon Jun 3 14:14:39 2024 |

Tyler | Update | FLIR | Initial CIT FROSTI Analysis |

| [Tyler]

Attached below are the initial results of the CIT FROSTI testing analysis.

|

| Attachment 1: CIT_FROSTI_Analysis_Group_Meeting-2.pdf

|

|

|

374

|

Mon Jun 3 14:59:44 2024 |

Cynthia | Update | Interferometer Simulations | Created cavity scan with LG modes |

|

| Attachment 1: ligo_update_6_3.pdf

|

|

|

375

|

Mon Jun 10 14:52:38 2024 |

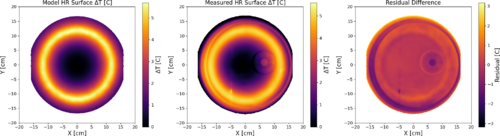

Tyler | Update | FLIR | CIT FROSTI Analysis Update |

| [Tyler]

Upon further inspection, one adjustment was made to the FROSTI profile analysis: changing the transmission value of the ZnSe viewport. It was initially assumed that the viewport possessed an AR coating, which would bring the transmission into the 90% range. Without the coating, it drops to roughly 70%. Assuming no coating, the estimated delivered power was calculated to be 11.7 W. This is consistent with the estimated power given from the Hartmann sensor analysis, thus it is believed that the viewport indeed had no coating.

| Quote: |

| [Tyler]

Attached below are the initial results of the CIT FROSTI testing analysis.

|

|

| Attachment 1: FROSTI_HR_Temperature_Difference-7.png

|

|

|

376

|

Fri Jun 14 13:32:13 2024 |

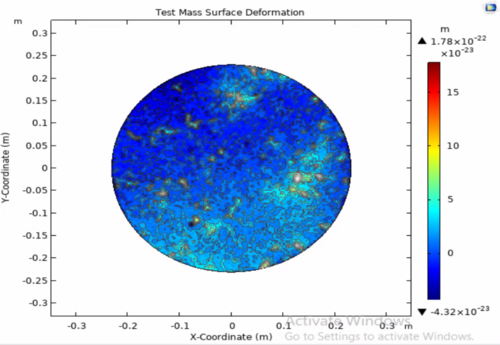

Liu | Update | Scripts/Programs | COMSOL simulation on rectangular heater elements design |

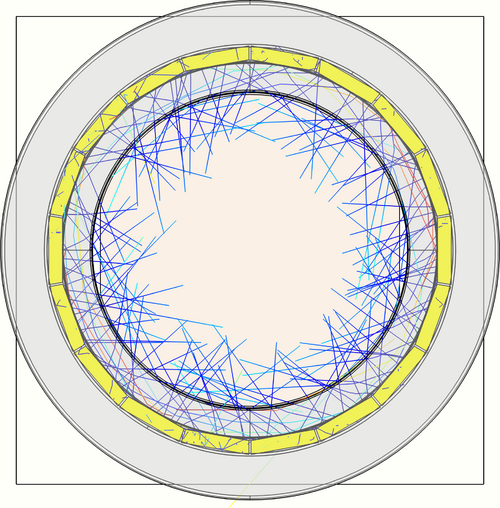

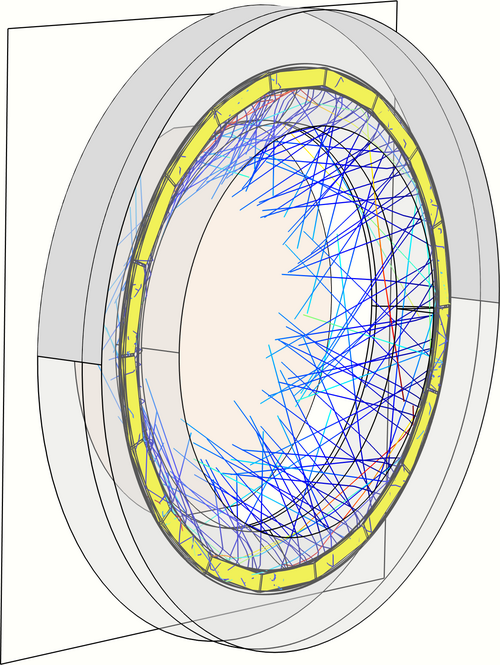

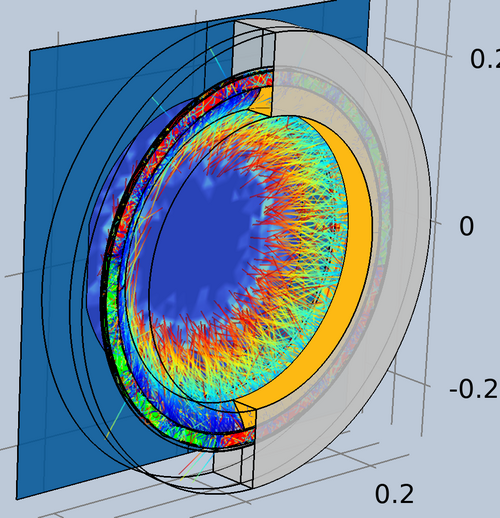

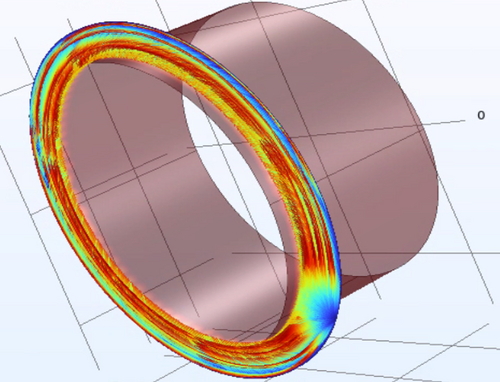

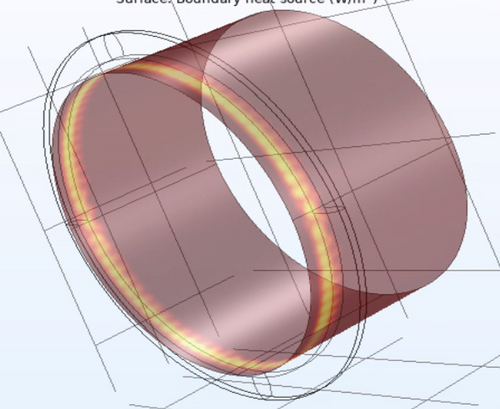

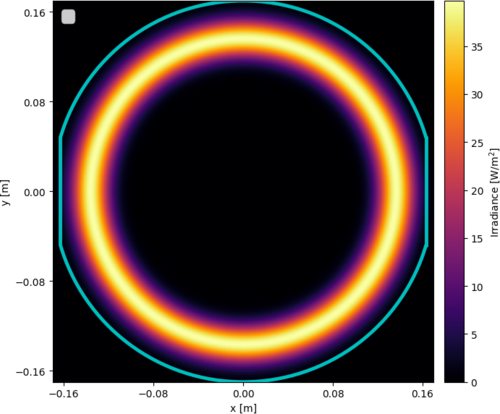

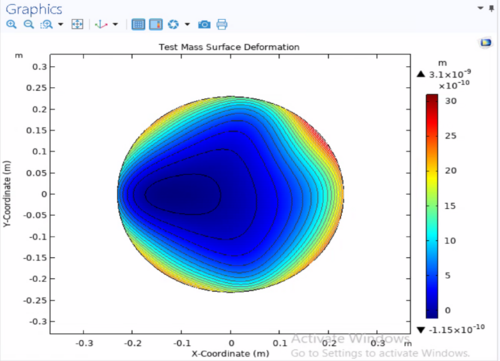

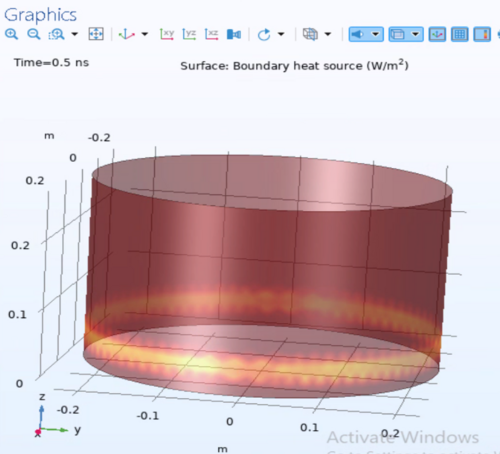

I have been looking at the feasibility of an alternative heater element design for FROSTI that replaces the original ring-like heater elements with n rectangular elements with straight edges. They form an n-sided regular polygon that could well approximate the original annular ring if n is large enough. This eliminates curved surfaces requirement for the heater elements, which was the source of the many month production delay for the prototype parts.

This design was implemented in COMSOL, shown in the attached. From the face on view, each element has a trapezoid shape with straight edges. The edges between neighboring elements are parallel, with a space of 2 mm in between them.

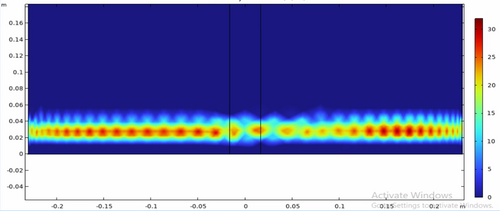

The ray tracing and thermal analysis obtained from COMSOL are shown in the attached pdf.

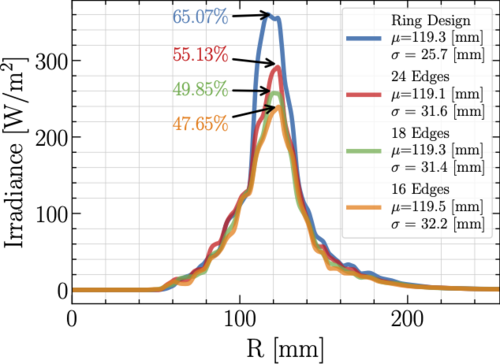

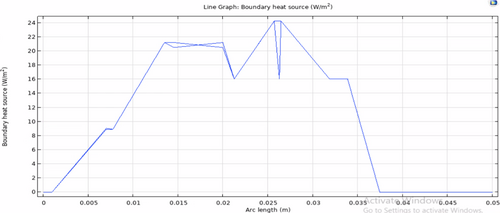

In particular, the 2D irradiance profiles were obtained from the ray tracing (so far from the front heating surfaces only). The 1D radial profiles were integrated and shown in the attached. The power delivery efficiency for the original ring-like heater element design is integrated to be roughly 65%, for comparison. The plot also shows the radial irradiance profiles for three different straight-edge designs, which correspond to 16 edges, 18 edges, and 24 edges. We see that with the straight-edge designs, the irradiance profiles stay in a good Gaussian shape. In addition, with a larger number of edges, the power efficiency increases, but is always less than the case for the optimized ring-like design.

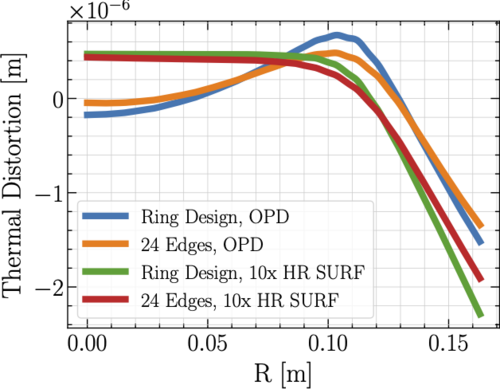

The thermal distortions for the TM were also obtained from COMSOL, using the irradiance profiles at the TM HR. As shown in the attached, with the straight-edge design, the effects on the thermal lens OPD and the HR surface deformation are similar to the ring design, but with less severe edge roll-off for instance. |

| Attachment 1: rayIllu_full.png

|

|

| Attachment 2: rayIllu_side.png

|

|

| Attachment 3: rayIllu_zoom.png

|

|

| Attachment 4: thermal_distortions.png

|

|

| Attachment 5: results.pdf

|

|

| Attachment 6: Irradiance_profile.png

|

|

|

378

|

Wed Jun 19 18:45:14 2024 |

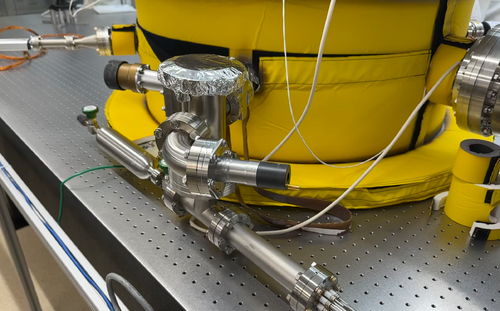

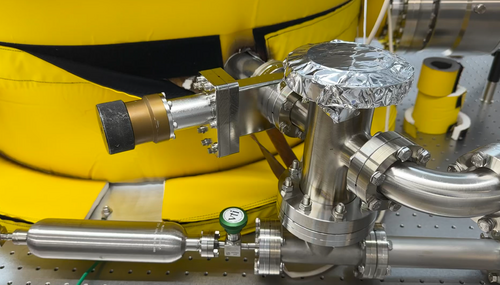

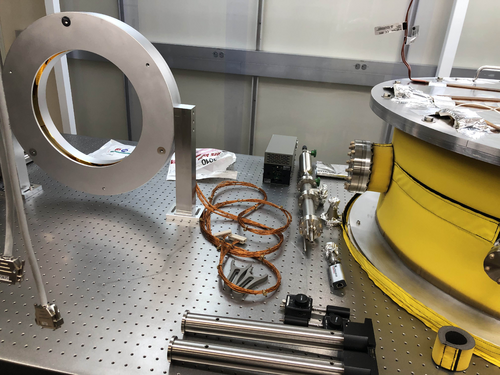

Luke | Update | | Vacuum chamber reassembly |

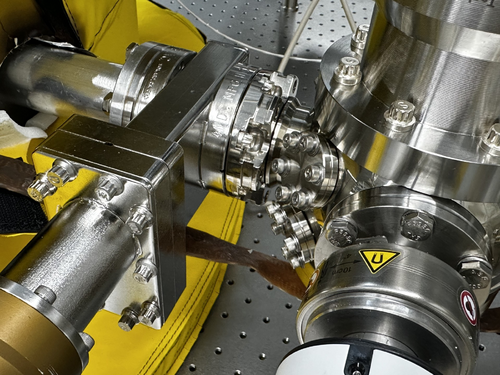

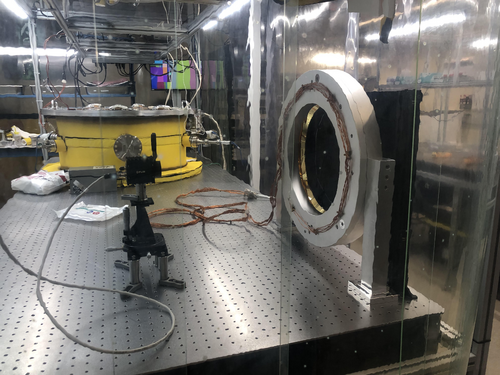

| [Luke, Aiden, Mohak , Tyler]

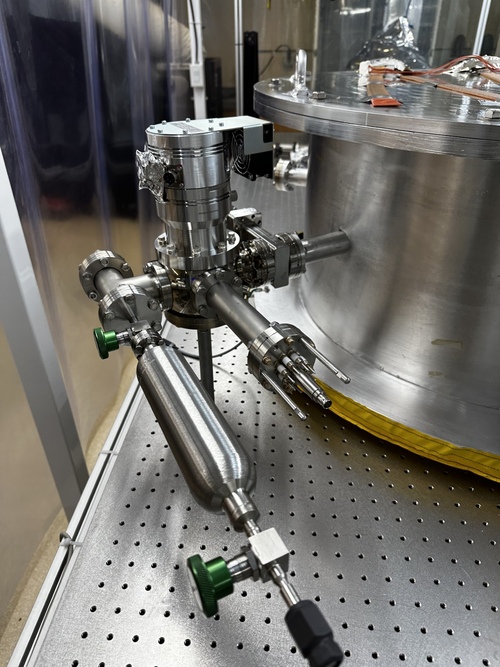

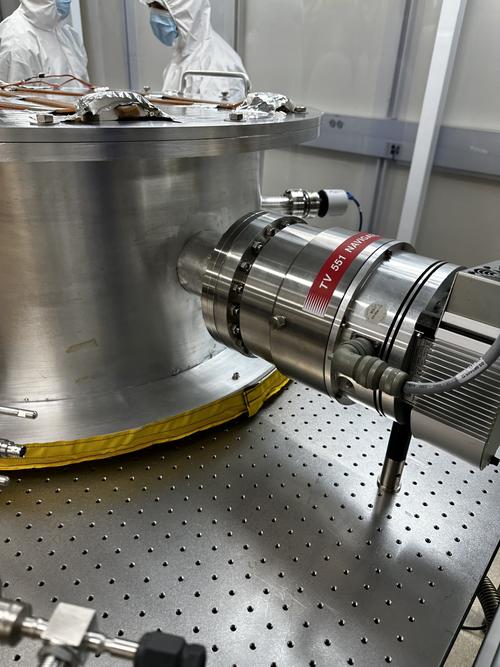

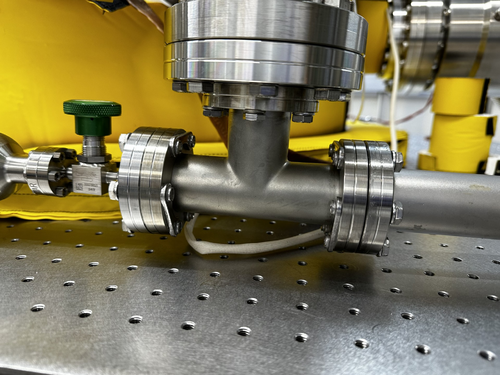

On Tuesday we had the silver screws for the spherical cube shortened by a quarter of an inch so that they would fit into the gate valve. We then attached the spherical cube to the vacuum chamber.

On Wednesday we finished assembling the RGA line and the main turbo pump. |

| Attachment 1: image_2024-06-19_182556383.png

|

|

| Attachment 2: image_2024-06-19_182631737.png

|

|

| Attachment 3: IMG_1710.jpg

|

|

|

380

|

Fri Jun 21 11:47:30 2024 |

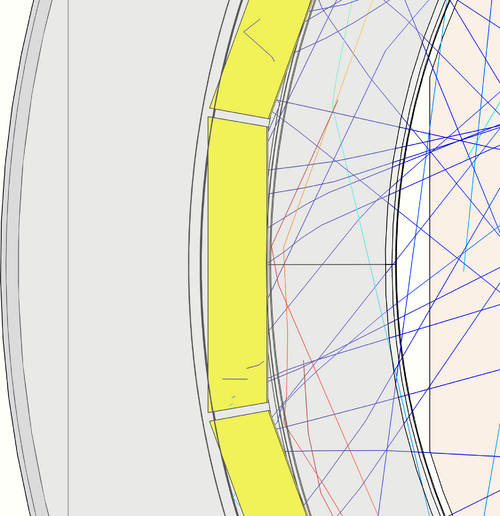

Liu | Update | Scripts/Programs | COMSOL simulation on alternative straightened heater elements design |

In the previous post, we saw that for the heater element design with straight edges in replacement of the current eight-element ring-like design, it provides the similar Gaussian-like irradiance profiles, but with smaller power delivery efficiencies, as shown in the plot. This turned out to result in similar but less prominent thermal effects.

They only differ from the original baseline design by a source power rescaling, however, as shown in the plot, where we see the power-rescaled irradiance profiles for the straight edge designs are close to that for the ring design. The resulting temperature profiles and thermal distortions are shown in plot and plot. The thermal effects for the 16 straight-edge design with renormalized source power for instance are strikingly similar to that for the original ring design.

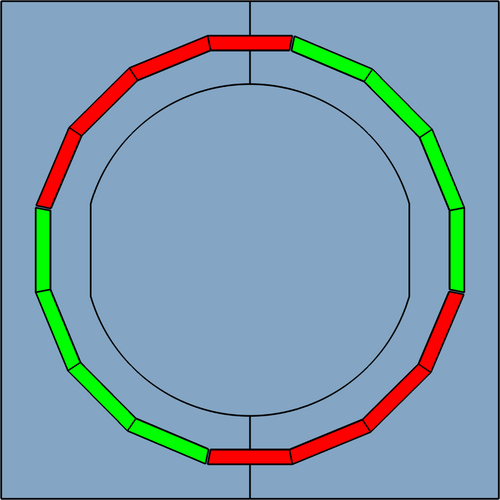

An alternative straightened heater element design has also been investigated with COMSOL FEA simulation. As shown in the attached, in this new design each heater element component is cut with multiple straight edges but remains connected, shown in the same colors (green and red). In the example, four straight edges are cut from each of the four heater components (4x4=16 edges in total). There is no spacing between the neighboring edges from the same element component, but the edges from different components are separated by 2mm, as can be seen in the attached. This new N-in-one straight edge design offers similar irradiance compared to that for the evenly-spaced N-sided regular polygon straight edge design with the same number of edges, as shown in the plot. It however has fewer heater components, four in this case, which makes it easier to implement in assembly and wiring, and less vulnerable to electrical and thermal shorts with their fewer heater element pins. |

| Attachment 1: rayIllu_side_new.png

|

|

| Attachment 2: rayIllu_full_new.png

|

|

| Attachment 3: Irradiance_profile.pdf

|

|

| Attachment 4: Irradiance_profile_norm.pdf

|

|

| Attachment 5: temp_profile.pdf

|

|

| Attachment 6: thermal_distortions.pdf

|

|

|

381

|

Mon Jun 24 14:28:51 2024 |

Cynthia | Update | Interferometer Simulations | SIS cavity with thermal effect |

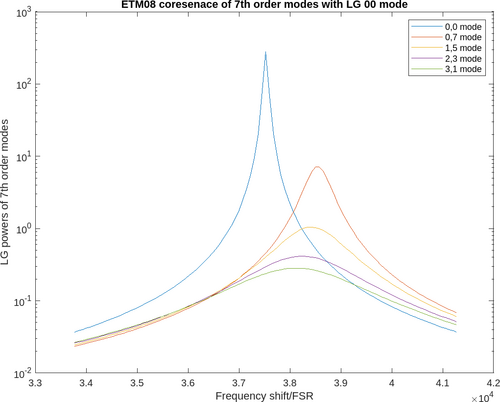

| tried to run a cavity scan with thermal deformation and ring heater for ITM04 ETM08 (aLIGO mirrors). Not sure about the accuracy of the graph as there is some commands that still need to verified. |

| Attachment 1: ETM08thermal.png

|

|

|

383

|

Tue Jun 25 12:34:18 2024 |

Shane | Update | Cleanroom | cleanroom cleaning and particle count |

|

[Luke, Shane, Xuejun, Mohak, Michael, Tyler, Cynthia]

cleaning cleanroom and particle count

- 10:45 am: ran zero count test on particle counter

- 11:02 am: started particle count

- zone 3:

- 0.3 u: 3284

- 0.5 u: 1247

- 1.0 u:332

- zone 4:

- 0.3 u: 1829

- 0.5 u: 581

- 1.0 u: 207

- 11:15 am: began hepavac of rest of lab

- 11:19 am: began surface check and wipedown, including softwalls

- 11:32 am: finished hepavac of rest of lab

- 11:35 am: started vacuuming the cleanroom floor

- 11:45 am: finished vacuuming the floor

- 11:47 am: started mopping the floor

- 11:55 am: finished mopping the floor

- 11:56 am: started cleaning the buckets

- 11:57 am: started mopping with IPA wipes

- 12:02 pm: finished mopping with IPA wipes

- 12:03 pm: changed sticky floor mats

- 12:04 pm: started particle count

- zone 3:

- 0.3 u: 3117

- 0.5 u: 374

- 1.0 u: 124

- zone 4:

- 0.3 u: 4531

- 0.5 u: 540

- 1.0 u: 0

|

|

384

|

Tue Jun 25 17:19:42 2024 |

Luke | Update | VAC | Vacuum chamber leak checking |

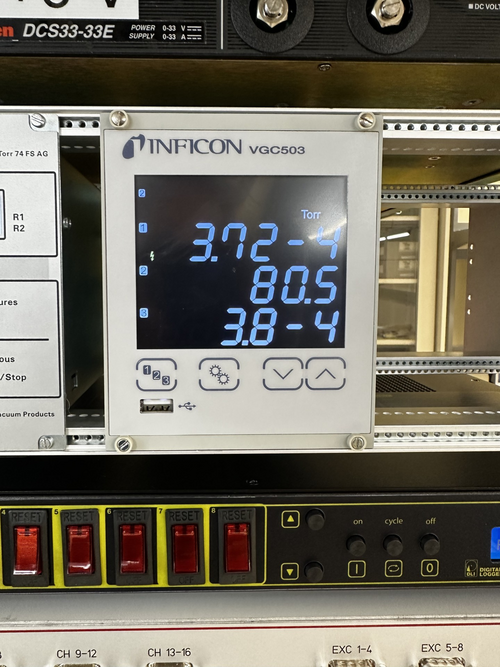

| Currently our main leak is in the RGA line. We found this by closing the gate valve from the main volume to see if which side was leaking more.

After identifying this we are pumping down the main volume to see how low it can go the third attachment was taken at 4:16 6/25/24. Pumping started around 3:15.

We have not been able to find exactly which flange is leaking, but our guess is on the small blanks and where the cube attaches to the gate valve as seen in the second attachment.

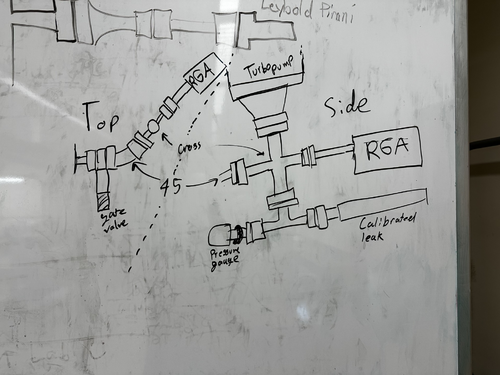

We will try a few more things and if the leak is not found/fixed we are planning on changing the configuration of the RGA line to remove the spherical cube, which we believe to be the problem. See fourth attachment for rough sketch of initial idea.

We have all of the parts required and they are clean and double bagged in 1129. I have not yet made all the measurements to confirm that this design is feasible. |

| Attachment 1: image_2024-06-25_170036021.png

|

|

| Attachment 2: image_2024-06-25_170057738.png

|

|

| Attachment 3: image_2024-06-25_170120030.png

|

|

| Attachment 4: image_2024-06-25_171238788.png

|

|

|

386

|

Wed Jun 26 16:39:34 2024 |

Luke | Update | VAC | Vacuum chamber leak checking |

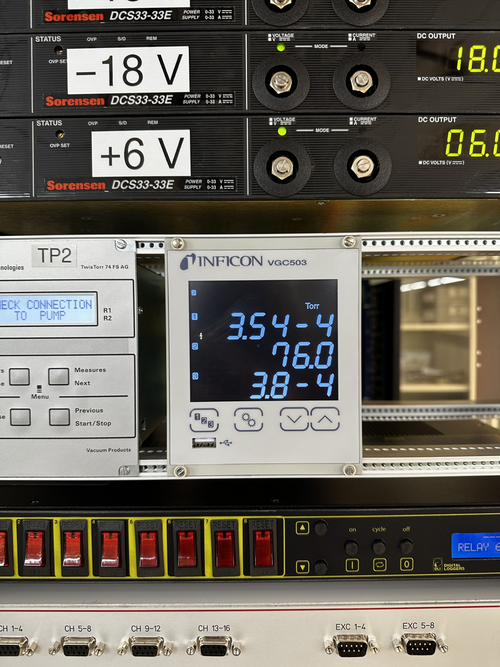

| On Tuesday I had isolated the main volume and let it pump down over-night. Today, Wednesday, I checked it and it had only gone down by a small amount compared to when I left it on Tuesday.

I then proceeded to tighten down the bolts attaching the tubo-pump to the zero-length reducer while it was under vacuum. This caused the pressure to drop down a few orders of magnitude. |

| Attachment 1: image_2024-06-26_162539705.png

|

|

| Attachment 2: image_2024-06-26_162601616.png

|

|

|

387

|

Thu Jun 27 11:09:14 2024 |

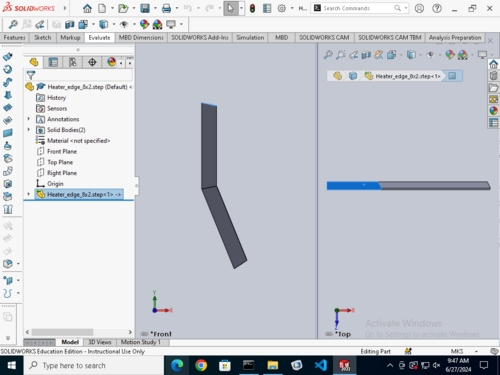

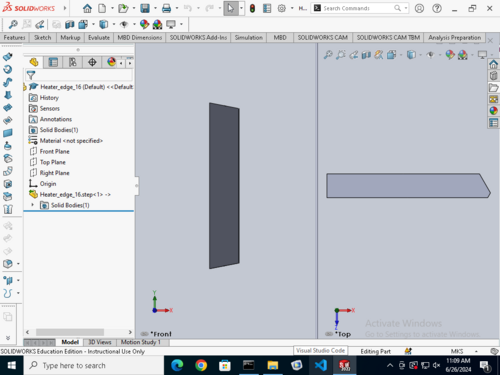

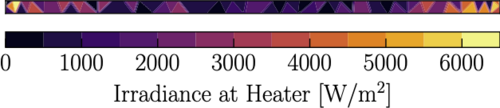

Liu | Update | Scripts/Programs | Straight edge STEP files and ray loss analysis |

Drawings and CAD models of the straight-edge designs are exported, and are visualized in SOLIDWORKS. Two are attached. One is a single edge of the evenly spaced polygon design with 16 edges, and the other is the 8x2 design, with two neighboring edges grouped together to replace the original single curved heater.

For the straight edge design in COMSOL, ray power detectors were placed at the heater's front surface. The irradiance is shown in figure. The amount of light rays deposited back to the heater is small when close to the center, where it is closer to the original ring. The ray power increases as we move further away from the center toward the edges. In addition, the total power integrated at the heater's front surfaces is about 21% of the original heater's emitted power. This could account for the power efficiency difference between the straight edge design and the ring design, as shown in plot for instance. |

| Attachment 1: edge_CAD_8x2_step.PNG

|

|

| Attachment 2: edge_CAD_step.PNG

|

|

| Attachment 3: Irradiance_frontheater.png

|

|

| Attachment 4: Irradiance_profile.pdf

|

|

|

388

|

Thu Jun 27 13:42:02 2024 |

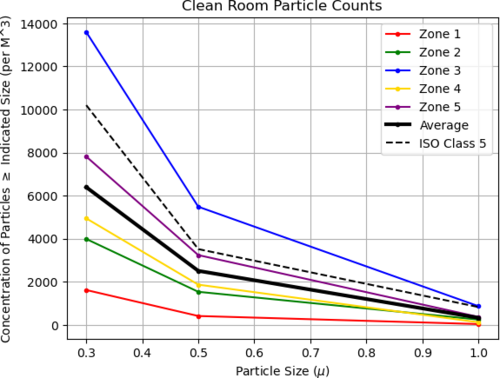

Shane | Update | Cleanroom | cleanroom 5 zone particle count measurement |

| Here's today's 5 zone measurement of the cleanroom. We're above the limit by a bit in zone three (all three size ranges), likely as a result of the recent work installing FROSTI, so it could probably use another focused cleaning. Everything else is below the limit. |

| Attachment 1: 24.png

|

|

|

389

|

Fri Jun 28 10:43:13 2024 |

Xuejun | Update | Cleanroom | Frosti |

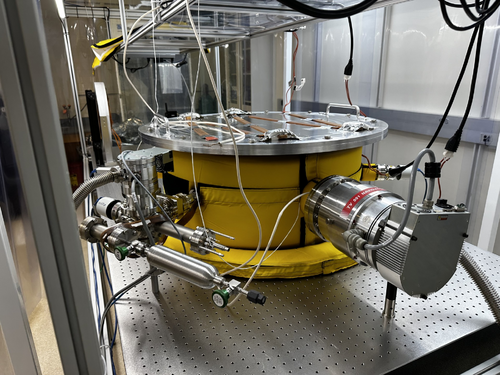

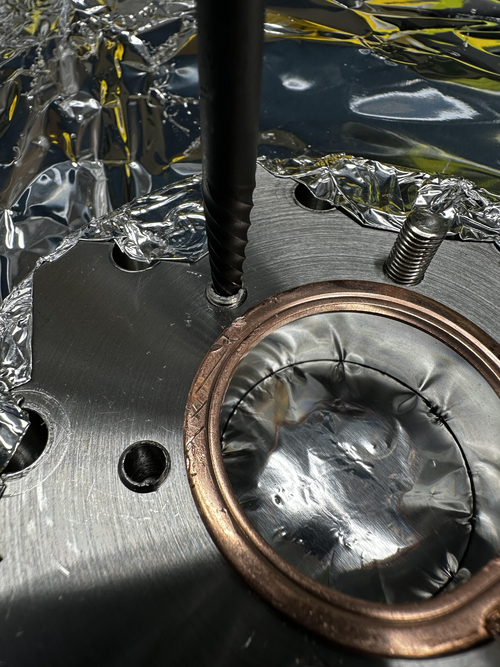

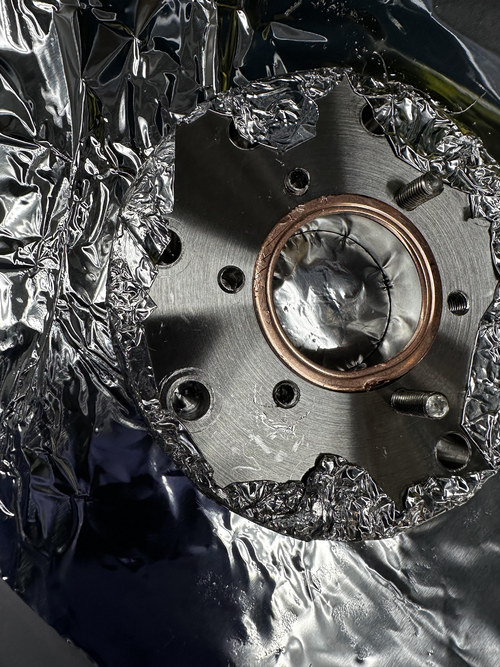

| [Xuejun, Tyler]

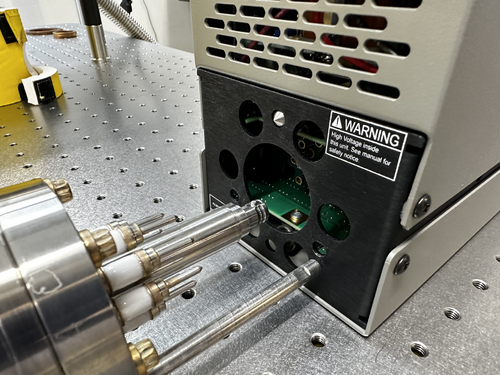

We moved Frosti into the cleanroom and debugged it to make sure everything was working. One of the DB25 pins broke off at the connector for element 1 so it needed to be recrimped. Element 6 short circuited but fixed with adjustment to the heater power pin position. We connected the power and sensor connectors to the power box and recalibrated the RTD sensors.

|

| Attachment 1: frosti.jpg

|

|

| Attachment 2: chassis.jpg

|

|

|

390

|

Fri Jun 28 18:15:16 2024 |

Luke | Update | VAC | Vacuum chamber |

We will be configuring the RGA line to remove the spherical cube from the system. Currently our plan for the new design is to connect a 4.5" to 2.75" Reducing Cross to the gate valve on the vacuum system. It will be orientated vertically with the turbo pump on top coming off the end will be a 90 deg elbow. On the bottom there will be a 4.5" to 2.75" Zero length reducer attached to that will be a Tee on one side the pressure sensor and the other the RGA. Connected to the elbow will be the calibrated leak.

The only parts not readily available are the ZLR and the 2.75" gaskets

| Part name |

Count needed |

Status/comment |

| 2.75" Tee |

1 |

In use in current RGA line |

| 4.5" to 2.75" Reducing Cross |

1 |

Needs to be clean and baked |

| 4.5" to 2.75" Zero length reducer |

1 |

To be purchased |

| 2.75" 90 deg elbow |

1 |

Clean needs to be removed from another part |

| 5/16 - 24 X 2.00" Bolts and nuts |

16 |

8 in clean room and plenty in storage they will need to be clean and baked. Plenty of nuts in clean room.

|

| 1/4 - 28 X 1.25" Bolts and nutplates |

24 |

12 in use in RGA line and 12 in storage that will need to be clean and baked. Sufficient nutplates in clean room |

| 1/4 - 28 X 7/8" Bolts |

12 |

Plenty of bolts in clean room |

| 2.75" Copper Gasket |

6 |

5 gaskets in clean room and none in storage. So some will need to be purchased |

| 4.5" Copper Gasket |

2 |

About 10 in clean room |

|

|

391

|

Mon Jul 1 11:45:45 2024 |

Sid | Update | Interferometer Simulations | |

| Progress update: Most of last week was spent getting set up with SIS, and learning how to do basic simulations. The goal for this week is to begin reproducing the methodology from T2000338. I have begun with studying perturbations to mirror curvature and position in a simple FP cavity, but thus far have been unable to get the same results. |

|

392

|

Mon Jul 1 15:19:42 2024 |

Cynthia | Update | Interferometer Simulations | O4 and O5 mirror cavity scans with thermal effect |

|

| Attachment 1: cavityScan_07_01.pdf

|

|

|

393

|

Fri Jul 5 13:17:44 2024 |

Liu | Update | Interferometer Simulations | Four-quadrant FROSTI-like RH for astigmatic thermal actuation for CE optics |

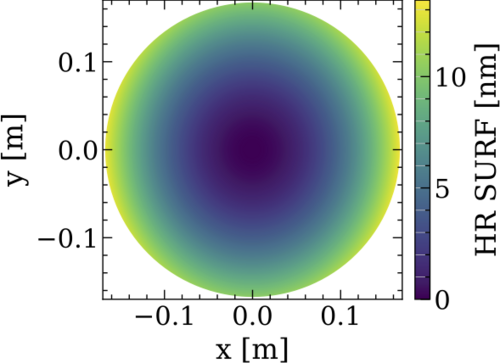

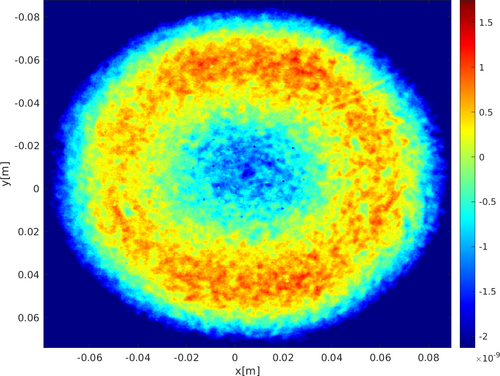

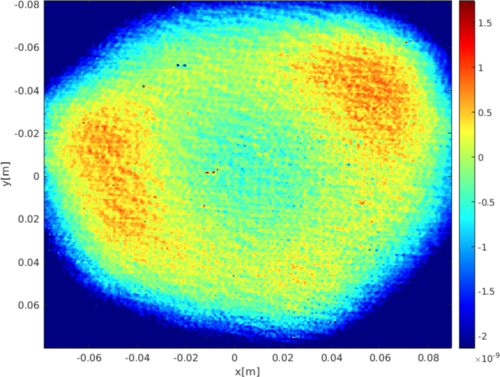

| In the CE corner layout design and down selection study, interferometer layouts with large incidence angles on some of the curved optics are being considered, such as the folding mirrors in the "long crab". This however generates astigmatic beams upon reflection and results in mode mismatches in coupled cavities that need to be mitigated. Astigmatic thermal actuation for the optics involved is thus essential. One way we are considering is to implement a FROSTI-like barrel RH that delivers different irradiance for the four quadrants. This post summarizes primitive results on the astigmatic thermal actuation for the HR surface by powering the heater elements from one diagonal differently compared to the other.

For this study, we looked at a simple case with an aLIGO-like test mass geometry (R=0.17m, H=0.2m) plus a barrel RH with 0.02m width at 0.03m from the AR surface with FEniCSx. The irradiance profiles are constant inside the width along the longitudinal direction, and zero outside the width. For the baseline non-astigmatic actuation with constant irradiance azimuthally. We have obtained roughly equal quadratic actuations along the x and y directions, as shown in figure. The total delivered power on the entire barrel is normalized to 1 W. The actuation on the curvature per power Delta S/Delta P in this non-astigmatic case thus is 0.835 uD/W.

For the astigmatic case however, the irradiance for the regions from one diagonal is increased by a given amount, compared to the non-astigmatic case, whereas for the other diagonal regions is decreased by the same amount (thus the total power is unchanged at 1 W). The HR deformation when the power is changed by 50%, for instance, is shown in picture, where the deformation along the x direction is larger than the y direction. The deformation in each direction however remains quadratic, with different curvature per powers for the x and y components, as shown in plot. The actuation on the curvature per power for an increasing amount of astigmatism is shown in plot. In terms of Zernike polynomials, the maximum amount of Z22 (astigmatism) for 1 W of total power is 2um while the remaining curvature content (Z20) is 6nm. This is shown in plot. |

| Attachment 1: SURF_05.png

|

|

| Attachment 2: SURF_xy.pdf

|

|

| Attachment 3: SURF_dsdp_converge.pdf

|

|

| Attachment 4: SURF_dsdp_astigs.pdf

|

|

| Attachment 5: overlaps_zers.pdf

|

|

| Attachment 6: SURF_xy_nonastig.pdf

|

|

| Attachment 7: SURF_xy_nonastig.pdf

|

|

|

394

|

Fri Jul 5 14:12:32 2024 |

Liu | Update | Interferometer Simulations | CE BS Mechanical Resonances |

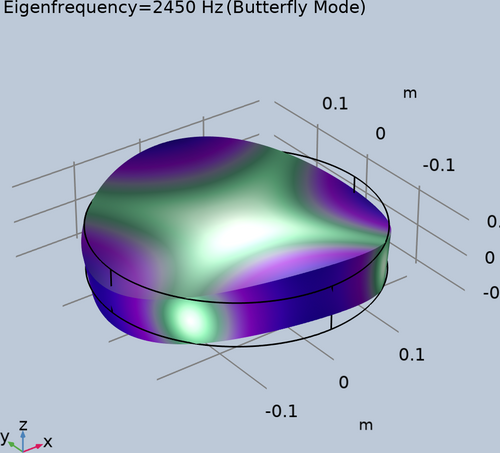

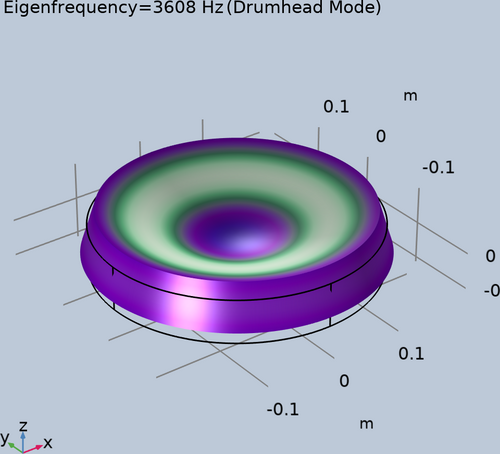

| The butterfly and drumhead mechanical modes for the aLIGO BS were calculated in COMSOL. The resonant frequencies for the two acoustic modes are 2.45 kHz and 3.61 kHz, matching the results in reference for instance.

For a quick projection for the resonant frequencies going from aLIGO to CE, the height and width of the BS are increased assuming the mass is increased from 14 kg to 70 kg, while keeping the aspect ratio fixed. The resonant frequencies for the two mechanical modes as a result becomes smaller, to 1.43 kHz and 2.11 kHz respectively, risking getting in the detection band.

Next step is to implement a mechanical ring with high stiffness outside the BS barrel to combat the decrement of the resonant frequencies of the relevant mechanical modes. |

| Attachment 1: butterfly.png

|

|

| Attachment 2: drumhead.png

|

|

|

395

|

Fri Jul 5 14:23:13 2024 |

Liu | Update | Interferometer Simulations | Engineering drawings for straight edge heater element designs for FROSTI |

| Step files and engineering drawings for the straight edge heater element designs have been created in COMSOL and SolidWorks. They are available in the group Git Repo. With those, we will initiate a discussion with the ceramics supplier for an estimate of the feasibility and benefits of the straight edge element over the curved element in terms of manufacturing cost and time. |

|

396

|

Mon Jul 8 10:39:14 2024 |

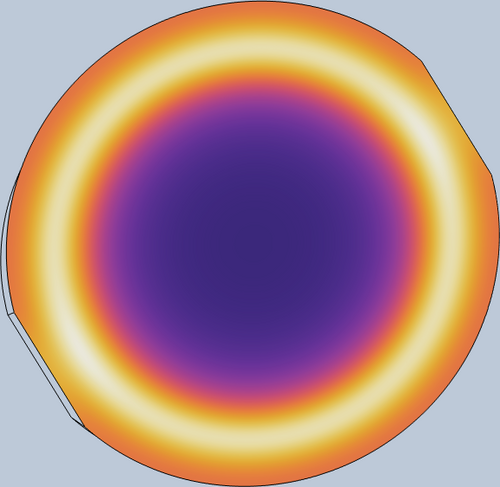

Xuejun | Update | FLIR | Average Temperature Profile |

After taking data for each of the individual heater elements, I imported them into python and overlayed them to produce an average temperature profile. I rotated the 7 of the elements to align with element 1's profile and averaged them out. By setting the range to 28C - 33C (this gave the best visibility of the heating pattern) it gave the profile attached. |

| Attachment 1: Average-Temperature-Profile.pdf

|

|

|

397

|

Mon Jul 8 12:26:10 2024 |

Michael | Update | Interferometer Simulations | Minimizing Astigmatic Effects in the SRC of LIGO |

| This is the first look and analysis of the effects of astigmatism in the aLIGO optical layout which can lead to mode mismatch and therefore increased losses into higher order modes. Specifically I am currently looking at measuring the effect of changing the radii of curvature of the SRC mirrors https://docs.google.com/presentation/d/1qhIehqyNukg4g8S2fqfQZz83yr9aB76tEa6fn2J-TrM/edit?usp=sharing |

|

398

|

Mon Jul 8 17:01:45 2024 |

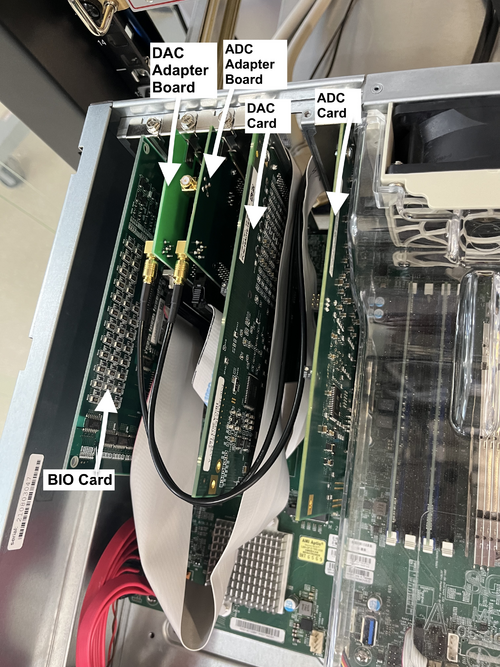

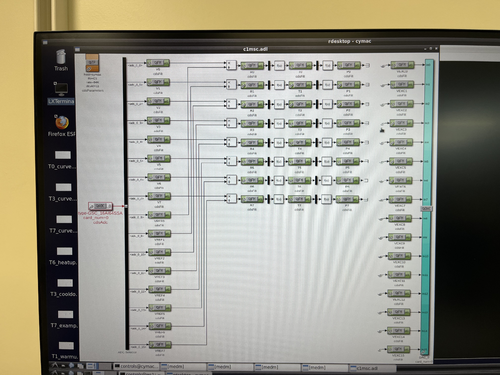

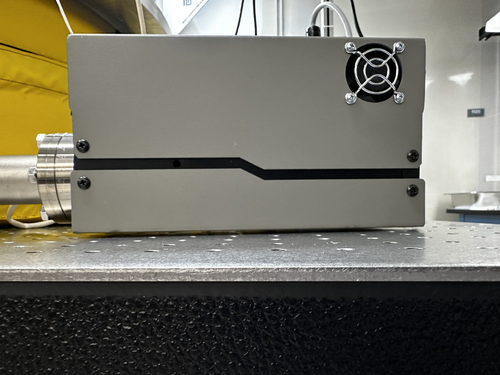

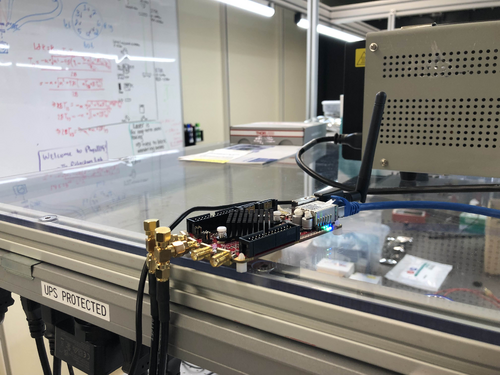

Shane | Update | CDS | New CyMAC internal layout |

| [Jon, Shane]

Internal layout of CyMAC has been updated (labeled image attached) to accommodate the replacement of the two ribbon cables. Looking down on the chassis from the front, and going from left to right, the new placement is as follows: BIO card, DAC adapter board, ADC adapter board, DAC card, ADC card. NOTE: As part of ADC-DAC loopback testing, we're disconnecting from the FROSTI readout chassis and using the cables to connect directly from ADC input channels to DAC output channels . Initial testing confirmed functionalility of all 32 ADC input channels and the first 8 DAC output channels. |

| Attachment 1: updated_cymac.jpeg

|

|

|

399

|

Tue Jul 9 18:19:50 2024 |

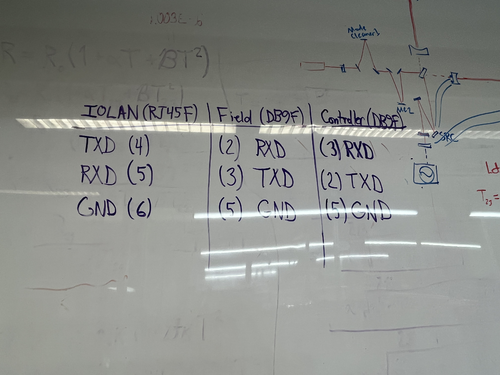

Shane | Update | CDS | ADC-DAC loopback testing and IOLAN installation |

| [Shane, Jon]

Finished ADC-DAC loopback testing today (see attached xlsx file or access directly here). All looks well with the first 8 channels, with the gain hovering just under 2. Also edited c1msc model in simulink to add channels 7-15 (the last 8 channels), and changed the rate back to 64K. See image 1 for the updated c1msc model. The last 8 channels are also looking good and show no problems, with slightly more scattering for the gain, but all values very close to 2.

We also installed the new eight-channel Perle IOLAN SDS8 terminal server today. Image attached.

NOTE: When we were installing it, we noticed an energized wire dangling from the 24V power supply. Has since been fixed and put back into place. |

| Attachment 1: iolanServerTerminal.jpeg

|

|

| Attachment 2: ADC-DAC_Loopback_Testing.xlsx

|

| Attachment 3: updatedc1msc.jpeg

|

|

|

400

|

Wed Jul 10 17:31:07 2024 |

Luke | Update | VAC | RGA line disassembly and upgrade |

[ Luke, Cynthia, Michael, Xuesi, Anthony ]

Started work around 12:45

We vented the chamber first and once it reached atmospheric pressure we started taking apart the RGA line.

We removed the parts in this order: Calibrated leak, RGA, Pressure gauge, 2.75" Blank on Tee, 2.75" Tee, all 1.33" Blanks on the cube, 4.5" feed through port, and finally the cube. Everything went smoothly after every part was taken off we covered the ends in Aluminum foil to maintain cleanliness.

We then started the assembly of the new line. The parts were added in this order: Reducing cross, ZLR, Tee, Cal leak, RGA, 90 deg Elbow, and Pressure sensor.

We left off the Turbo pump as of now because we weren't able to find a 1" post not in use and we didn't want to put too much weight on the cross. We also noticed that the RGA might not fit on its probes because of a slight tilt to the cross and by extension the Tee. If this ends up being a problem we might need to remove all the parts connected to the cross so that we can reposition it so that the 2.75" rotating flange is connected to the gate valve.

Ended work around 4:00 |

| Attachment 1: image_2024-07-10_172112210.png

|

|

| Attachment 2: image_2024-07-10_172431863.png

|

|

| Attachment 3: image_2024-07-10_172603090.png

|

|

| Attachment 4: image_2024-07-10_172823966.png

|

|

|

401

|

Thu Jul 11 15:53:39 2024 |

Luke | Update | VAC | RGA line upgrade |

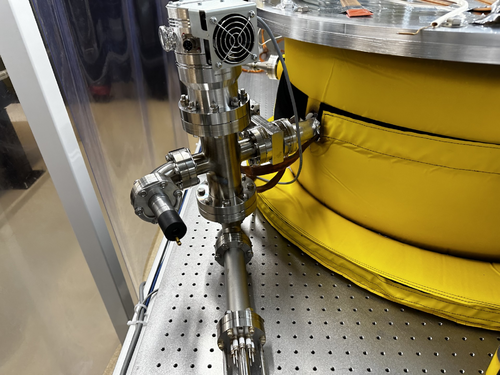

[ Luke, Jon ]

Started work at 11:00

As mentioned in my previous post the RGA was not clearing the table because of a tilt in the cross. So I removed the 90 deg elbow, loosened the bolt securing the Tee to the ZLR, and removed the cross from the gate valve. I then spun around the Tee on the bottom so that the cal leak would be pointing in the right direction and connected the rotating 2.75" flange of the cross to the gate valve. I then added the small turbo pump to the top of the cross.

Then with the help of Dr. Richardson, we made some adjustments to how the Tee was oriented with respect to the cross and how the cross was with respect to the table. So that the cal leak and RGA would fit on the table. After that we made some changes to the bolting of the ZLR to reducing cross replacing the 2.00" bolts and nuts with 1.75" bolts and nut plates. We did face some difficulty with half of the 2.00" bolts which required a bit of torque to get them out.

Finished work at 2:20

Things to do:

Before we start pumping down the system again Dr. Richardson wanted two other changes to be made. To replace the 2.75" to 1.33" conical reducer with a zero length reducer. He also wants the bolts that hold the main turbo pump to be replaced with nut plates.

I plan on starting this work on Friday (7/12) before pumping down over the weekend |

| Attachment 1: image_2024-07-11_154630323.png

|

|

| Attachment 2: image_2024-07-11_154818191.png

|

|

| Attachment 3: image_2024-07-11_154902840.png

|

|

|

403

|

Sat Jul 13 15:09:04 2024 |

Luke | Update | General | Ring heater COMSL model update |

After the feedback from last meeting and Liu's help narrowing down what I should do to improve the model. I made some changes: First with Liu's help I made the proportions of the test mass and ring heater much more reasonable and parametrized by constants. Second from Cao's paper "FROSTI Nonimaging Reflector Design" Liu showed me what I should do to define the elliptical mirrors. Third during Friday's modeling/programming meeting walked me through getting the different irradiance plots to work. |

| Attachment 1: image_2024-07-13_150654436.png

|

|

| Attachment 2: image_2024-07-13_150704735.png

|

|

| Attachment 3: image_2024-07-13_150716079.png

|

|

| Attachment 4: image_2024-07-13_150726593.png

|

|

|

404

|

Mon Jul 15 09:36:44 2024 |

Liu | Update | Interferometer Simulations | ETM Profile Optimization for FROSTI |

This is to optimize the FROSTI heating profile for ETM, by minimizing the residual RMSE of the HR surface deformation after the beam size weighted curvature is removed by the current RH. The parameters of the profile being explored are the location, width, and total power for the Gaussian Annulus. As shown in the attached series of plots, the optimal location is 9.9 cm, with a width of 7.7 cm, and a total FROSTI power of 12.7 W (for 1 W of Gaussian beam absorption). The residual RMSE is 1.2 nm. About 0.5% of the FROSTI power is lost at the edges of the TM.

For comparison, without FROSTI, the residual RMSE after the beam size weighted curvature removed by the current RH is 44.5 nm. When the width of the Annulus is set to be 3 cm however, the residual RMS is 3.1 nm, with much smaller FROSTI power needed at 4.7 W, and less power loss at 0.02%. |

| Attachment 1: pdf_merged.pdf

|

|

|

405

|

Mon Jul 15 13:30:49 2024 |

Luke | Update | VAC | Problem with 2.75" to 1.33" zero length reducer |

| Last Friday while checking the depth of the ZLR I got one of the screws stuck. Today I tried a couple things to get it out. First I tried a few different pliers to be able to grip lower on the screw this didn't work. So I switched to the other method of drilling a small hole to see if maybe the threads would pull away from the walls of the hole a bit. This kind of worked as seen in the picture below I was able to remove most of the screw but there is a bit still stuck which I was not able to remove and I didn't want to use a larger bit for fear of damaging the tapped hole. |

| Attachment 1: IMG_1882.jpg

|

|

|

406

|

Mon Jul 15 14:28:32 2024 |

Pooyan | Update | Interferometer Simulations | aLIGO test mass surface profiles |

Created a Google Slides presentation to summarize all the mirror surface map information that we use for simulating interferometers.

A+ expected maps are based on correspondence with G. Billingsley. The estimate for the A+ ITMs will be to take the “as polished” data and add coating non-uniformity to it. (T2000398) Neither of these are scaled for the precise thickness of the Ti:Ge coatings.

Google Slides link: https://docs.google.com/presentation/d/1ge-ciAiEdNyyTvSShYdZz2JpACFRY2W3JDpxHRqMnOQ/edit?usp=sharing

|

|

407

|

Mon Jul 15 14:49:06 2024 |

Pooyan | Update | Computers | Synology NAS server setup |

Installed a Synology NAS server (Synology RackStation RS1221) in lab room 1129, with host name “scribe” and ip “192.168.1.17”. It is mounted on the rack and each of its 8 storage bays has a 2TB SSD disk. It will be used to set up automated backups of all the lab machines (e.g., chimay, logrus, megatron).

One shared storage is set on it with SHR-2 as its RAID type. It can tolerate the failure of two disks and has 10.4TB of total capacity.

We can use both rsync and dd to create backups of the system. A suggested backup schedule could be daily rsync backups and bi-weekly disk snapshots using dd.

|

|

408

|

Mon Jul 15 15:44:52 2024 |

Cynthia | Update | Interferometer Simulations | performed cavity scans with thermal effects and ring heater |

|

| Attachment 1: cavity_scan_07_15.pdf

|

|

|

409

|

Mon Jul 15 15:52:40 2024 |

Michael | Update | Interferometer Simulations | aLIGO locking with varying SRC mirrors and measuring mode mismatch |

|

| Attachment 1: SRC_Astigmatism_Analysis_7_15_24.pdf

|

|

|

410

|

Tue Jul 16 18:43:07 2024 |

Shane | Update | CDS | ADC-DAC loopback testing and IOLAN installation |

|

UPDATE:

Follow up ADC-DAC loopback testing now complete, matching all the ADC channels to a single DAC channel, and then matching all the DAC channels to a single ADC channel (see attached xlsx file or access directly here). Also note c1msc model file has been updated to include the second set of 16 ADC channels. The newly added channels also have their own filter modules, but those are not needed for anything other than the loop-back testing and can now be deleted if we don't want to keep them.

| Quote: |

| [Shane, Jon]

Finished ADC-DAC loopback testing today (see attached xlsx file or access directly here). All looks well with the first 8 channels, with the gain hovering just under 2. Also edited c1msc model in simulink to add channels 7-15 (the last 8 channels), and changed the rate back to 64K. See image 1 for the updated c1msc model. The last 8 channels are also looking good and show no problems, with slightly more scattering for the gain, but all values very close to 2.

We also installed the new eight-channel Perle IOLAN SDS8 terminal server today. Image attached.

NOTE: When we were installing it, we noticed an energized wire dangling from the 24V power supply. Has since been fixed and put back into place. |

|

| Attachment 1: Follow-up_ADC-DAC_Loopback_Testing.xlsx

|

|

411

|

Mon Jul 22 18:19:34 2024 |

Luke | Update | VAC | Zero length reducer stuck bolts |

Today, I borrowed a bolt extractor drill bit from the machine shop to remove some stuck bolts from the zlr. Before starting, I laid down a sheet of aluminum foil on the work table and wiped down all the tools I was going to use. I began by drilling a small pilot hole and then enlarged it with a 5/32 drill bit. However, when I attempted to use the bolt extractor, it didn't grip the bolt effectively. Our bolts were too seized, causing the extractor bit to repeatedly slip instead of gaining traction. |

| Attachment 1: image_2024-07-22_181607501.png

|

|

| Attachment 2: image_2024-07-22_181632965.png

|

|

|

413

|

Mon Jul 29 12:18:52 2024 |

Liu | Update | Interferometer Simulations | Update on FROSTI O5 ETM profile optimization |

| Update on FROSTI O5 ETM profile optimization is attached. |

| Attachment 1: pdf_merged.pdf

|

|

|

414

|

Mon Jul 29 12:20:56 2024 |

Liu | Update | Interferometer Simulations | Update on wavefront actuation with astigmatically driven RH for CE |

| Update on wavefront actuation with astigmatically driven RH for CE is attached. |

| Attachment 1: SURF_nonastig_merged.pdf

|

|

|

415

|

Mon Jul 29 12:23:10 2024 |

Liu | Update | Interferometer Simulations | Update on mechanical resonances of CE BS with stiffener ring |

| Update on mechanical resonances of CE BS with stiffener ring is attached. |

| Attachment 1: eigen_freqs_merged.pdf

|

|

|

416

|

Mon Jul 29 13:39:16 2024 |

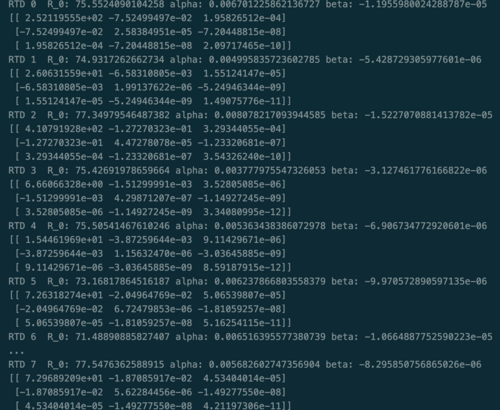

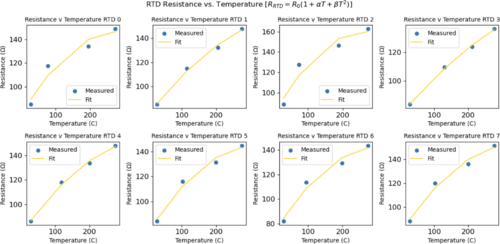

Tyler | Update | DAQ | RTD Parameter Calibration |

| [Tyler]

Using the data taken during the FROSTI testing at Caltech, I attempted to find a better calibration of the RTD sensors, given our past issues with inaccurate readings. The fit parameters, alpha and beta, are still all different from the initial values given to us by Fralock (alpha = .003, beta = 1.003e-6, R_0 was not given), but the true values will differ based on factors such as part geometry.

| Quote: |

| Refitted RTD calibration, neglecting quadratic term:

R_0 (ohm) Alpha (1/C)

RTD 0 79.3962 0.002031

RTD 1 78.2874 0.002530

RTD 2 80.9775 0.002381

RTD 3 74.2947 0.003684

RTD 4 80.3199 0.002157

RTD 5 78.2106 0.002297

RTD 6 76.6825 0.002438

RTD 7 82.6645 0.002458

Measurements taken can be found here. An uncertainty of 1 C was assumed for temperature.

| Quote: |

| [Jon,Tyler]

We noticed that the RTD temperature readings given on the Cymac were off, and traced the issue to miscalibration in the relationship between the resistance and temperature of each RTD (Callendar-Van Dusen eqn). Below is the table of values inferred from independent measurements of temperature and resistance to rectify this problem. This data was then fitted to better determine the coefficients present in the temperature-resistance relation:

R_0 (ohm) Alpha Beta

RTD 0 80.8674 0.001315 4.273e-6

RTD 1 79.5704 0.001887 3.7873e-6

RTD 2 81.7334 0.002014 2.1724e-6

RTD 3 74.3060 0.003677 3.6022e-8

RTD 4 81.1350 0.001761 2.3598e-6

RTD 5 77.9610 0.002423 -7.5192e-7

RTD 6 78.7980 0.001373 6.2909e-6

RTD 7 83.8616 0.001890 3.3529e-6 |

|

|

| Attachment 1: RTD_Recal_params.png

|

|

| Attachment 2: RTD_recal_plots_fin.png

|

|

|

417

|

Mon Jul 29 14:30:16 2024 |

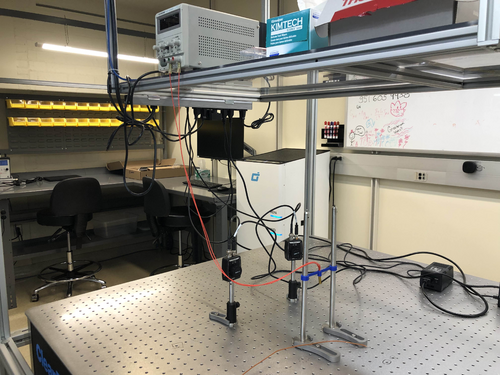

Tyler | Update | Cleanroom | RIN Measurement Set-up |

| [Tyler]

I have begun moving parts into the cleanroom for the upcoming FROSTI RIN tests that will be conducted within the next few weeks. While waiting for the rest of the equipment to arrive to perform the full-scale tests, I have additionally moved the FROSTI under the shelf above the optical table, where it will stay for the meantime. As always, please use caution when in the cleanroom. Aside from the FROSTI, the IR photodetectors that will be used for the test are delicate and costly to replace.

|

| Attachment 1: RIN_FROSTI.jpg

|

|

|

419

|

Fri Aug 2 13:50:22 2024 |

Shane | Update | CDS | Serial Comm. Test (Agilent Turbo Pump) |

| Did a brief communication test with the agilent turbo pump today, to see if we could get serial communications up and running for it. Used a simplified python script with sockets package to establish a connection and send a simple command to query the pump's operational status. The connection was successful, and had no issues establishing. The command also sent successfully, and received a response. The response didn't make sense, though, as all the possible statuses correspond to integers 0-7, and this test returned the integer 15. Need to troubleshoot some more to figure out why it's returning nonsense values. Possible match-up issue with the way the information is being encoded on each end? At the very least, connection and command sending are both working fine, and this showed that the pin-out connections we were assuming (image attached) are correct for basic connection to work. |

| Attachment 1: pinouts.jpeg

|

|

|

Draft

|

Sun Aug 4 09:01:01 2024 |

Michael | Update | Interferometer Simulations | Update on SRC Mode Mismatch Analysis |

| An update on my analysis to minimize mode mismatch/scattering by introducing toroidal mirrors to the SRC. |

| Attachment 1: SRC_Mode_Mismatch_Update_8_2_24.pdf

|

|

| Attachment 2: SRC_Mode_Mismatch_Update_8-12-24.pdf

|

|

|

421

|

Tue Aug 6 13:07:07 2024 |

Xuejun | Update | Interferometer Simulations | |

| [Xuejun]

The width and location of the measured in-air change in temperature profile has been determined to be 0.045m and 0.137m respectively. Subsequently, a fake irradiance profile was able to be generated that best resembled what the actual irradiance profile could be using this information for testing in COMSOL. The generated irradiance profile that output the most similar change in temperature profile as the measured in-air profile has been included as well as the change in temperature profile it produced on the blackbody screen "test mass" model in COMSOL. |

| Attachment 1: Thermal_model_image.png

|

|

| Attachment 2: generated_irradiance_profile.png

|

|

|

422

|

Mon Aug 12 16:24:34 2024 |

Tyler | Update | Cleanroom | RIN Measurement Update 1 |

| [Tyler]

For some preliminary tests, I moved the IR photodetectors outside of the cleanroom and onto the other optical table. The basic goal was to obtain a signal from both photodetectors. To achieve this, one of the heater cartridges used for early FLIR measurements months ago was hooked up to a power supply (PS). The PS was set to supply 0.20 A with a voltage of 2.8 V; the corresponding power is thus 0.56 W. With this, I was able to measure a signal using the Red Pitaya, the device that will be used for following RIN measurements.

| Quote: |

| [Tyler]

I have begun moving parts into the cleanroom for the upcoming FROSTI RIN tests that will be conducted within the next few weeks. While waiting for the rest of the equipment to arrive to perform the full-scale tests, I have additionally moved the FROSTI under the shelf above the optical table, where it will stay for the meantime. As always, please use caution when in the cleanroom. Aside from the FROSTI, the IR photodetectors that will be used for the test are delicate and costly to replace.

|

|

| Attachment 1: Basic_setup.jpg

|

|

| Attachment 2: RP.jpg

|

|

|

423

|

Mon Aug 12 16:35:30 2024 |

Luke | Update | | Ringheater modeling Update |

|

| Attachment 1: HR_surface_deformation.png

|

|

| Attachment 2: Irradiation_pattern_input.png

|

|

| Attachment 3: HR_surface_deformation_other.png

|

|

|

424

|

Mon Aug 12 17:09:04 2024 |

Cynthia | Update | Interferometer Simulations | O4 vs O5 cavity scans with ITM plume guess or ETM |

| So far the proposed solution for what to use for O5 ITM mirror for SIS simulations is either the plume guess file or using the O5 ETM mirror for ITM. I had ran a cavity scan for both of these possibilities and it seems like the results produced are fairly different. The next step is most likely moving on to adding the Frosti effects including both of the proposed possibilities, and before this, a few confirmations and verifications are needed using similar previous studies to make sure my code produce the right result. |

| Attachment 1: O5_plots_and_tables.pdf

|

|

| Attachment 2: O4_plots_and_tables.pdf

|

|

| Attachment 3: ETM12mapO5.png

|

|

| Attachment 4: Screenshot_2024-08-12_at_5.05.31_PM.png

|

|

|

425

|

Fri Aug 16 12:51:46 2024 |

Luis Martin | Update | VAC | Update on vacuum chamber status |

[Luis, Luke, Tyler]

Vacuum chamber parts were finally received and assembled. After whipping down the parts, the blank was removed from the reducing cross. Then, the zero-length reducer was attached. Lastly, we installed the T that had the argon leak and RGA. The final pump down showed signs of an improved seal since the pressure dropped quite fast. This pressure is well bellow the limit required to use the RGA, argon test leak could be performed some time next week. |

| Attachment 1: IMG_1910.HEIC

|

| Attachment 2: IMG_1911.HEIC

|

| Attachment 3: IMG_1909.HEIC

|

| Attachment 4: IMG_1912.HEIC

|

|

426

|

Mon Aug 19 07:11:55 2024 |

Cynthia | Update | Interferometer Simulations | cavity scans with FROSTI effects |

|

| Attachment 1: LIGO_update_8_19.pdf

|

|

|

427

|

Fri Aug 23 16:08:32 2024 |

Luke | Update | VAC | RGA line leak testing |

[Luke, Luis, Jon, Tyler]

On the 22nd Dr. Richardson showed Luis, Tyler and I how to preform a leak test with the RGA. We did the initiall test and found a few leaks two were particuarly bad highlighted in orenge below. To try and remidy this we planned on replacing the copper gaskests on the leaking flanges. We then began taking the two problem flanges off, but seven of the eight bolts holding on the turbo pump were over tightened and had seized. So after we got them off we postponed the rest of the work to the next day.

On the 23nd Luis and I reattached the badly leaking flanges with new copper gaskets. We then preformed the Helium leak test with the RGA. As seen in the table below we weren't able to majorly changed the leaks in the two flanges.

| Connection |

Initial |

After disassembly |

| Tee - RGA |

3.1e-9 -> 2.4e-9 |

9.2e-9 |

| Tee - Cal leak |

Low |

Low |

| Tee - ZLR (2.75"-4.5") |

Low |

9.2e-9 |

| ZLR (2.75"-4.5") - Reducing Cross |

2.1e-8 -> 1.9e-8 |

3.6e-8 -> 9.3e-9 |

| Cross - Elbow |

Low |

1.2e-9 |

| Elbow - Pressure sensor |

Low |

2.9e-9 |

| Cross - Turbo pump (small) |

2.1e-8 -> 3.1e-8 |

6.9e-8 -> 2.2e-8 |

| Cross - Gate valve |

Low |

Low |

| Gate valve - Port |

2.4e-9 -> 2.2e-9 |

1.2e-9 |

| Port - ZLR (6.0"-8") |

1.1e-9 |

N/A |

| ZLR (6.0"-8") - Turbo pump (large) |

Low |

N/A |

| Port - Pressure sensor |

Low |

N/A |

| Port - Up to air valve |

Low |

N/A |

| Port - Blank |

Low |

N/A |

| Port - Feed though port |

Low |

N/A |

| Lid |

Low |

N/A |

|

|

428

|

Mon Aug 26 14:42:04 2024 |

Cynthia | Update | Interferometer Simulations | current status on cavity scan with effects of FROSTI |

| I used the code and arm cavity model used for previous O5 study on mirrors and HOM (the pdf of the study and the result can be found at https://dcc.ligo.org/LIGO-G2100878), but it seems like the result I obtained is different from the study result. Since my cavity scans codes have a large portion of it relying on this code, I will have to go over the study result and the code to make sure there is no issue with that code itself first. There are also some other updates or issued encountered when I tried to plot the mirror maps with effects of FROSTI. |

| Attachment 1: LIGO_updates_8_26.pdf

|

|

|

429

|

Tue Aug 27 15:01:26 2024 |

Luke | Update | VAC | RGA line leak testing |

[Luke, Tyler]

On the 27th Tyler and I ran the RGA leak test again with the electron multiplier on. These were the leaks we measured. The chamber's overall pressure was at ~6e-8 torr.

| Connection |

Leak rate (torr) |

| Tee - RGA |

3.92e-11 (very low) |

| Tee - Cal leak |

4.77e-11 (very low) |

| Tee - ZLR (2.75"-4.5") |

4.97e-11 (very low) |

| ZLR (2.75"-4.5") - Reducing Cross |

2.45e-9 (low) |

| Cross - Elbow |

7.36e-11 (very low) |

| Elbow - Pressure sensor |

2.36e-11 (very low) |

| Cross - Turbo pump (small) |

8.07e-9 (lowish) |

| Cross - Gate valve |

4.02e-11 (very low) |

| Gate valve - Port |

2.27e-9 (low) |

| Port - ZLR (6.0"-8") |

1.11e-9 (low) |

| ZLR (6.0"-8") - Turbo pump (large) |

1.00e-10 (very low) |

| Port - Pressure sensor |

1.05e-10 (very low) |

| Port - Up to air valve |

1.08e-11 (very low) |

| Port - Blank |

5.58e-10 (very low) |

| Port - Feed though port |

1.21e-11 (very low) |

| Lid |

1.11e-11 (very low) |

|