| ID |

Date |

Author |

Type |

Category |

Subject |

|

378

|

Wed Jun 19 18:45:14 2024 |

Luke | Update | | Vacuum chamber reassembly |

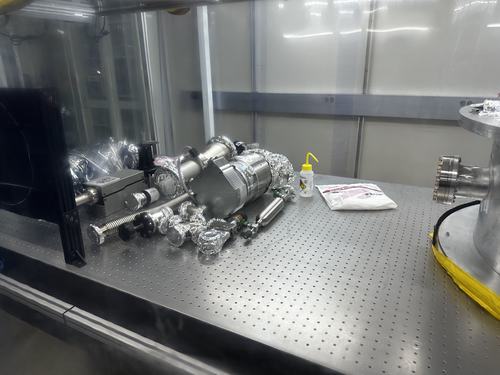

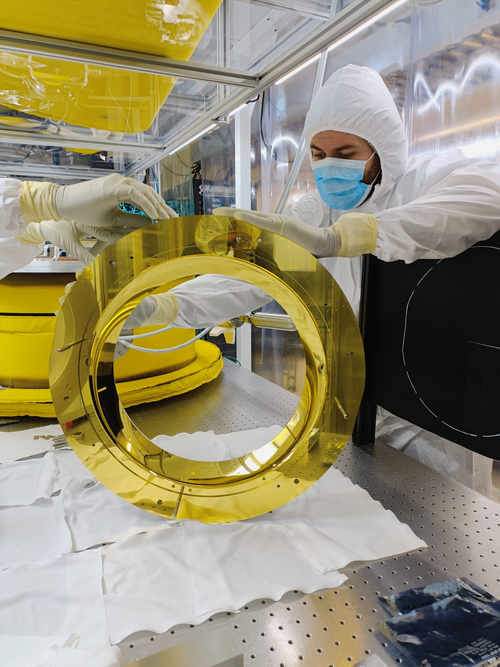

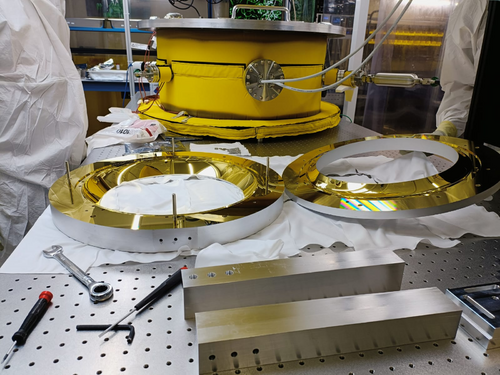

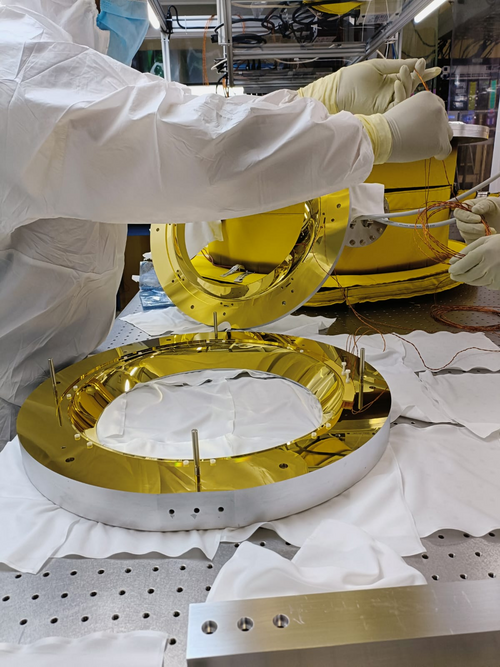

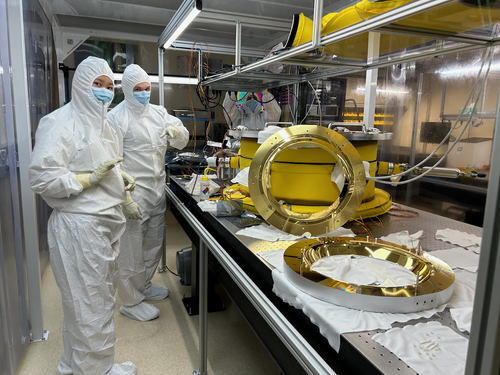

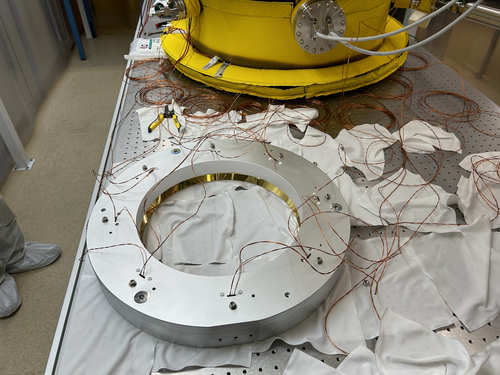

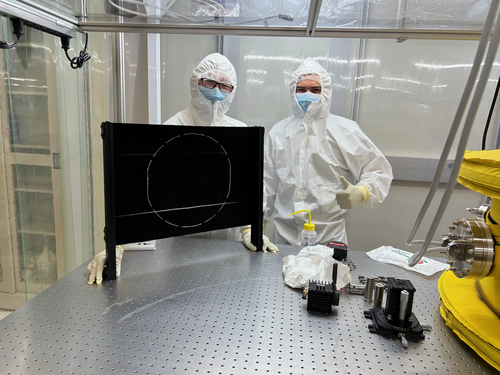

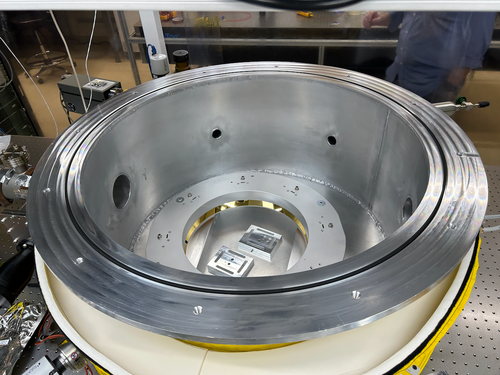

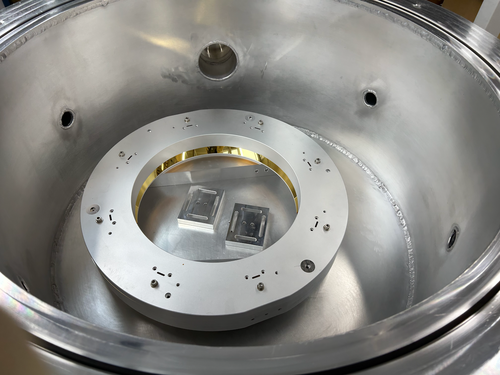

| [Luke, Aiden, Mohak , Tyler]

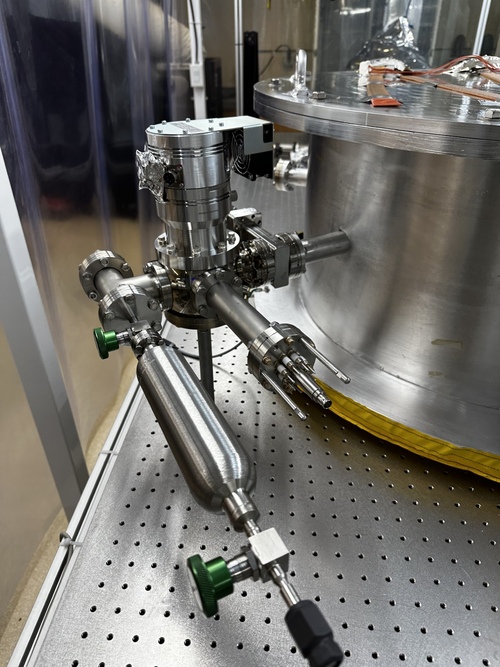

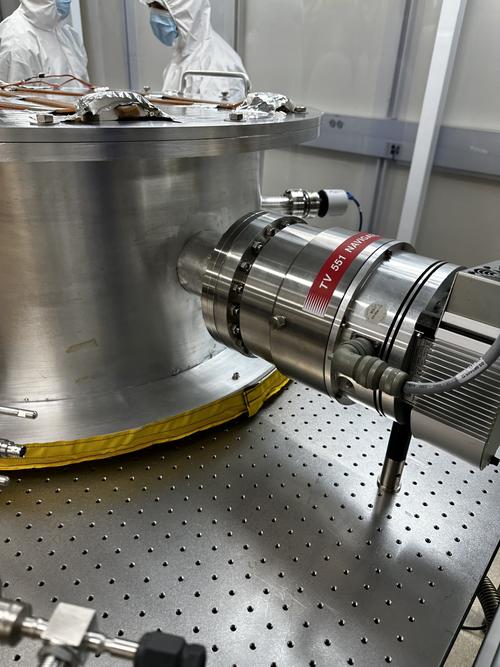

On Tuesday we had the silver screws for the spherical cube shortened by a quarter of an inch so that they would fit into the gate valve. We then attached the spherical cube to the vacuum chamber.

On Wednesday we finished assembling the RGA line and the main turbo pump. |

| Attachment 1: image_2024-06-19_182556383.png

|

|

| Attachment 2: image_2024-06-19_182631737.png

|

|

| Attachment 3: IMG_1710.jpg

|

|

|

377

|

Mon Jun 17 11:47:46 2024 |

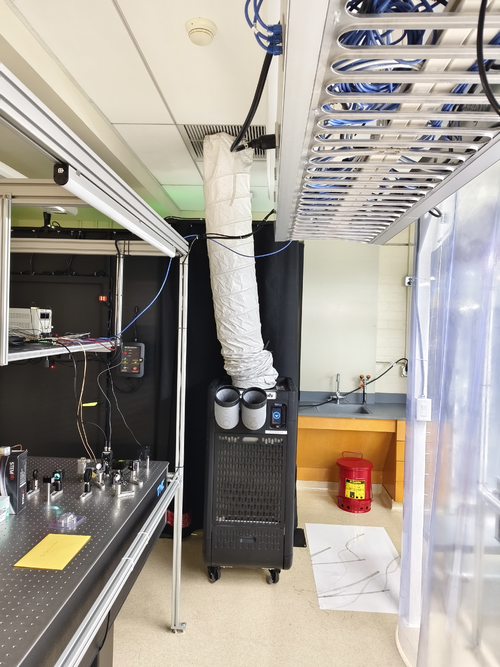

Liu | Infrastructure | General | Temporary cooling units for the labs |

| Below are the temporary cooling units installed last week in labs 1119 and 1129. They are the temp. replacement for the building AC system, which will be shut down during the Physics roof replacement. |

| Attachment 1: 1119.jpg

|

|

| Attachment 2: 1129.jpg

|

|

|

376

|

Fri Jun 14 13:32:13 2024 |

Liu | Update | Scripts/Programs | COMSOL simulation on rectangular heater elements design |

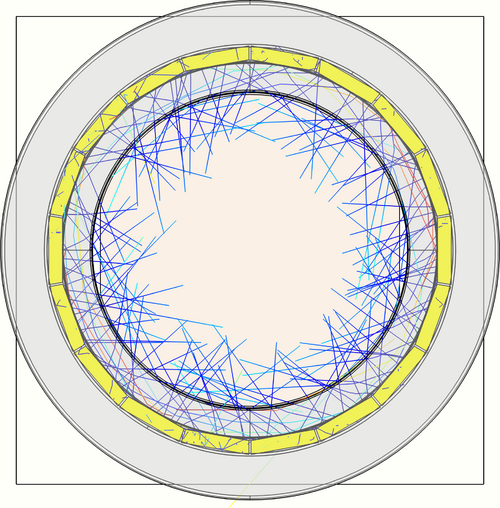

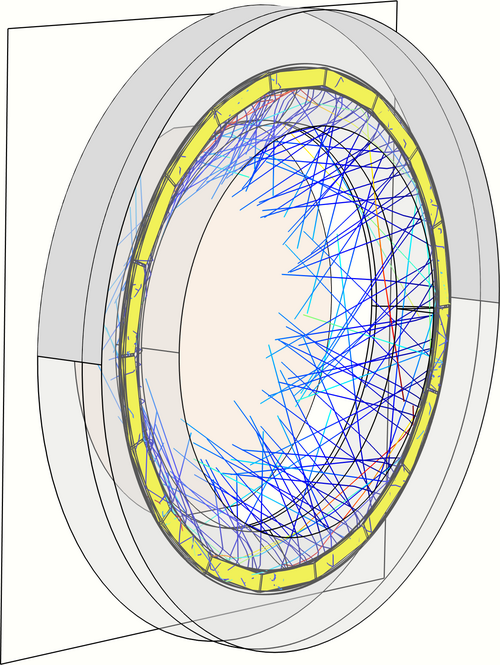

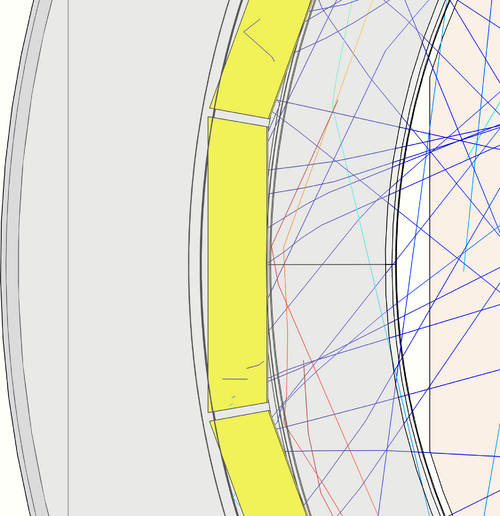

I have been looking at the feasibility of an alternative heater element design for FROSTI that replaces the original ring-like heater elements with n rectangular elements with straight edges. They form an n-sided regular polygon that could well approximate the original annular ring if n is large enough. This eliminates curved surfaces requirement for the heater elements, which was the source of the many month production delay for the prototype parts.

This design was implemented in COMSOL, shown in the attached. From the face on view, each element has a trapezoid shape with straight edges. The edges between neighboring elements are parallel, with a space of 2 mm in between them.

The ray tracing and thermal analysis obtained from COMSOL are shown in the attached pdf.

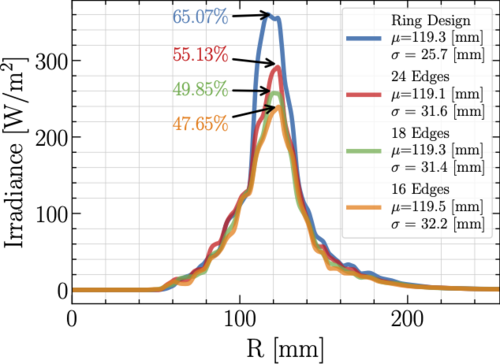

In particular, the 2D irradiance profiles were obtained from the ray tracing (so far from the front heating surfaces only). The 1D radial profiles were integrated and shown in the attached. The power delivery efficiency for the original ring-like heater element design is integrated to be roughly 65%, for comparison. The plot also shows the radial irradiance profiles for three different straight-edge designs, which correspond to 16 edges, 18 edges, and 24 edges. We see that with the straight-edge designs, the irradiance profiles stay in a good Gaussian shape. In addition, with a larger number of edges, the power efficiency increases, but is always less than the case for the optimized ring-like design.

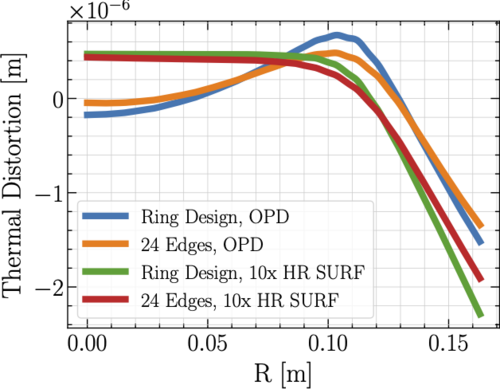

The thermal distortions for the TM were also obtained from COMSOL, using the irradiance profiles at the TM HR. As shown in the attached, with the straight-edge design, the effects on the thermal lens OPD and the HR surface deformation are similar to the ring design, but with less severe edge roll-off for instance. |

| Attachment 1: rayIllu_full.png

|

|

| Attachment 2: rayIllu_side.png

|

|

| Attachment 3: rayIllu_zoom.png

|

|

| Attachment 4: thermal_distortions.png

|

|

| Attachment 5: results.pdf

|

|

| Attachment 6: Irradiance_profile.png

|

|

|

375

|

Mon Jun 10 14:52:38 2024 |

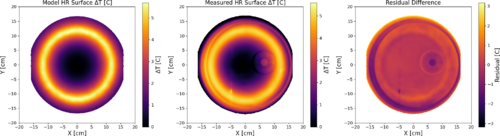

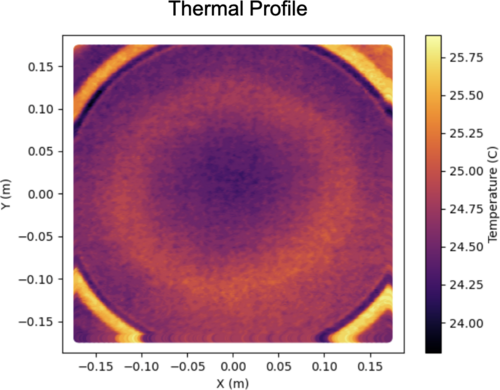

Tyler | Update | FLIR | CIT FROSTI Analysis Update |

| [Tyler]

Upon further inspection, one adjustment was made to the FROSTI profile analysis: changing the transmission value of the ZnSe viewport. It was initially assumed that the viewport possessed an AR coating, which would bring the transmission into the 90% range. Without the coating, it drops to roughly 70%. Assuming no coating, the estimated delivered power was calculated to be 11.7 W. This is consistent with the estimated power given from the Hartmann sensor analysis, thus it is believed that the viewport indeed had no coating.

| Quote: |

| [Tyler]

Attached below are the initial results of the CIT FROSTI testing analysis.

|

† |

| Attachment 1: FROSTI_HR_Temperature_Difference-7.png

|

|

|

374

|

Mon Jun 3 14:59:44 2024 |

Cynthia | Update | Interferometer Simulations | Created cavity scan with LG modes |

|

| Attachment 1: ligo_update_6_3.pdf

|

|

|

373

|

Mon Jun 3 14:14:39 2024 |

Tyler | Update | FLIR | Initial CIT FROSTI Analysis |

| [Tyler]

Attached below are the initial results of the CIT FROSTI testing analysis.

|

| Attachment 1: CIT_FROSTI_Analysis_Group_Meeting-2.pdf

|

|

|

372

|

Mon Jun 3 09:24:48 2024 |

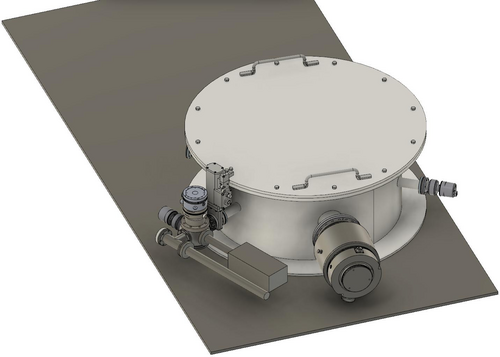

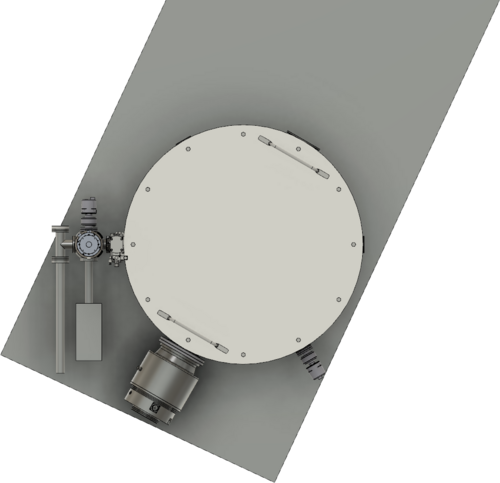

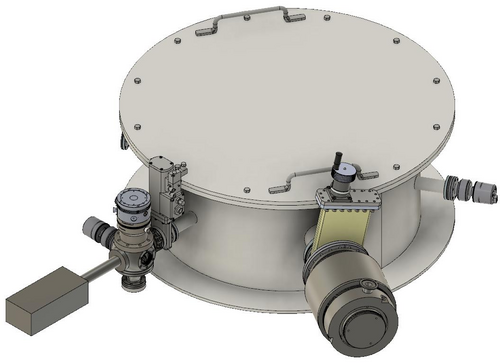

Aiden | Update | VAC | Vacuum Chamber Rendering |

| Here is a new render of the vacuum chamber that includes the 2.75 tee to place the Argon leak right next to the RGA. The conical reducer under the spherical cube was also replaced with a 4.5 blank. The height from the bottom of the blank to the bottom face of the chamber is 5.45". With the chamber now on 1" standoffs, we will need a support with a height of 6.45". |

| Attachment 1: VaccumChamberAssembly__Redesign_with_tee.jpg

|

|

| Attachment 2: VaccumChamberAssembly__Redesign_with_tee_top.png

|

|

|

371

|

Fri May 31 19:37:47 2024 |

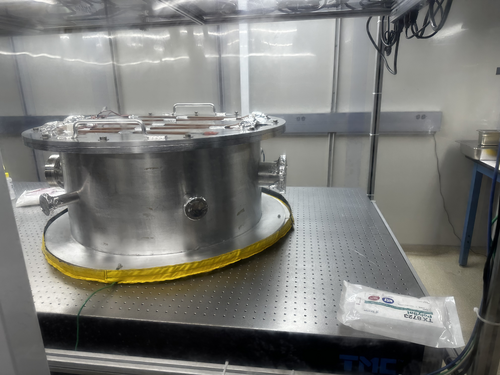

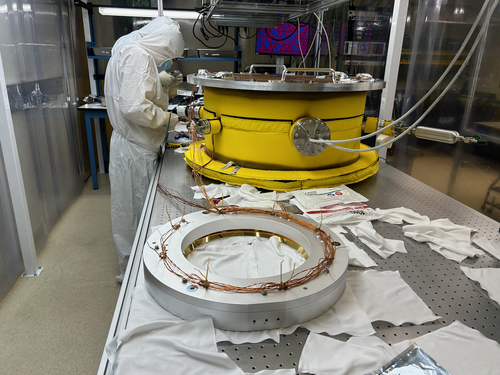

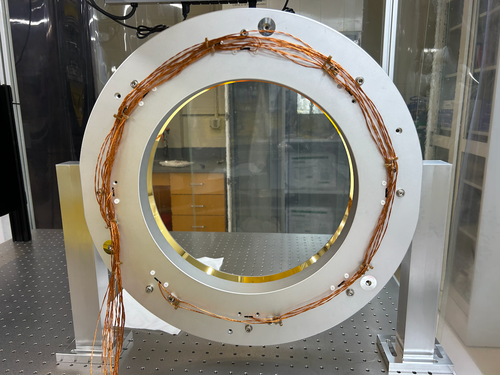

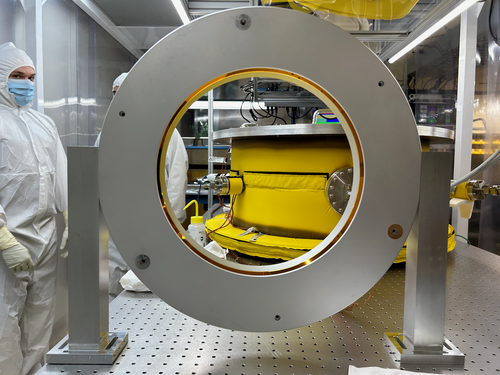

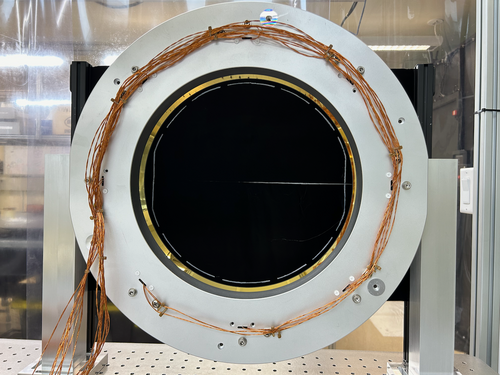

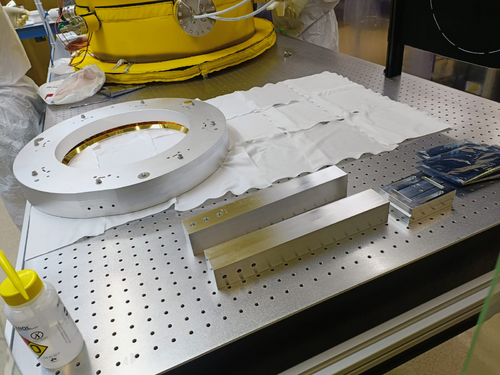

Luke | Update | | Vacuum chamber Disassembly |

| [Luke, Aiden, Jon, Michel, Tyler]

Work done:

On Tuesday (5/28) we removed the RGA line with minimal difficulty. On Wednesday (5/29) we removed the turbo pump, which had a few bolts that we needed to cut. We borrowed a dremel with ceramic blades from the machine shop to help remove some of the bolts. On Thursday we moved the vacuum chamber onto the floor to check and resecure the heating band on the bottom of the vacuum chamber. We then relocated the posts the vacuum chamber rests on closer to the end of the table and reinstalled the chamber. The postís height was also reduced from 2in to 1in.

Current state of vacuum chamber:

The vacuum chamber is currently reinstalled in its new position. Some of the parts on the table will be used in the assembly of the turbo pump and RGA lines with the others being able to be moved to storage. |

| Attachment 1: IMG_1681.jpg

|

|

| Attachment 2: IMG_1680.jpg

|

|

| Attachment 3: IMG_1680.jpg

|

|

| Attachment 4: IMG_1681.jpg

|

|

|

369

|

Thu May 16 15:23:14 2024 |

Shane | Update | Cleanroom | Cleanroom cleaning and particle count |

|

[Luis, Michael, Luke, Shane]

cleaning cleanroom and particle count

- 1:45 pm: ran zero count test on particle counter

- 1:50 pm: started particle count

- zone 3:

- 0.3 u: 2660

- 0.5 u: 332

- 1.0 u: 41

- zone 4:

- 0.3 u: 8106

- 0.5 u: 2494

- 1.0 u: 831

- 2:08 pm: began surface check and wipedown, including softwalls

- 2:22 pm: started vacuuming the floor

- 2:39 pm: finished vacuuming the floor

- 2:43 pm: started mopping the floor

- 2:53 pm: finished mopping the floor

- 2:54 pm: started cleaning the buckets

- 2:59 pm: started mopping with IPA wipes

- 3:06 pm: finished mopping with IPA wipes

- 3:10 pm: changed sticky floor mats

- 3:06 pm: started particle count

- zone 3:

- 0.3 u: 1496

- 0.5 u: 83

- 1.0 u: 0

- zone 4:

- 0.3 u: 789

- 0.5 u: 83

- 1.0 u: 41

|

|

368

|

Mon May 13 14:53:29 2024 |

Peter | Update | VLC Update | VLC |

| VLC Update WEEK 7 attached below |

| Attachment 1: VLC_Update.pdf

|

|

|

367

|

Mon May 13 14:48:27 2024 |

Aiden | Update | VAC | New Vacuum Chamber Design |

| I created a new model for the vacuum chamber based on the ideas from last week's meeting.

It should be noted that we can not have the zero length reducer and the gate valve on the same arm as they both have blind tapped holes. We need to decide if we want the gate valve or not as if we do, we will need to use the 3 inch long reducer.

Important Measurements:

From the back of the flange to the back of the RGA: 25.25 in

Height from bottom of the blank to the bottom of the chamber: 2.75 in |

| Attachment 1: VaccumChamberAssembly__Redesign_v5.jpg

|

|

|

366

|

Mon May 13 13:03:41 2024 |

Tyler | Update | FLIR | Readout Code Updates |

| [Tyler]

Some changes have been made to the FLIR readout code to help improve its functionality:

- More accurate temperature readings than before due to updates in the calculation procedure. A bug was causing one of the parameters to not update correctly; this is now fixed.

- Saved data now stored in HDF5 files rather than CSV.

- User can now enable automatic data storage by specifying a collection interval (in minutes). The choice of manually saving data is still present if desired.

Below is an image of the graphical interface. This is an old screenshot. Visually, there is no difference between the older and newer version. The differences come from the list above, which help the user more reliably measure and store data for later analysis.

|

| Attachment 1: AcquisitionImage(Jul-18-2023_15_24).jpg.png

|

.jpg.png.png)

|

|

365

|

Tue May 7 20:34:31 2024 |

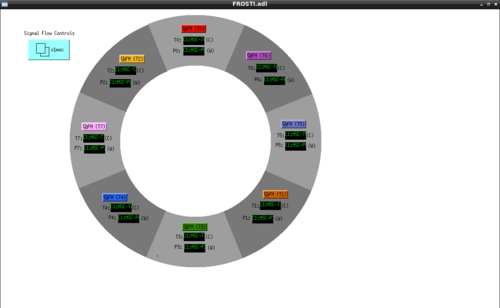

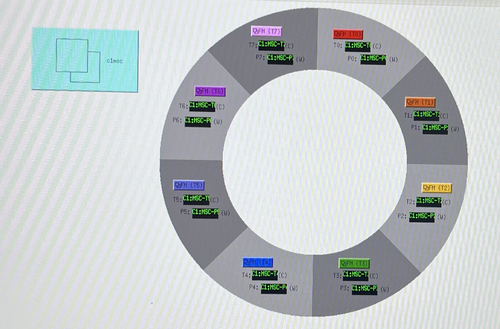

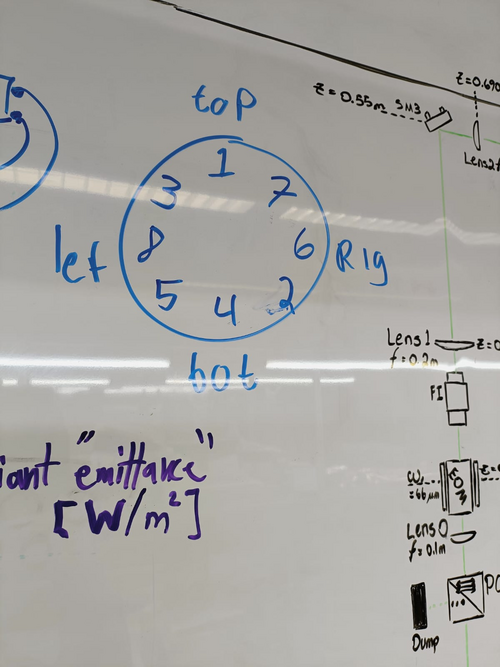

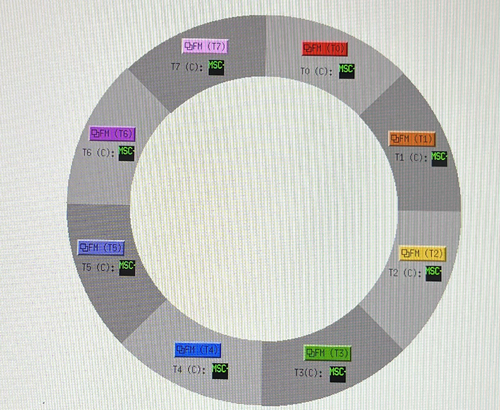

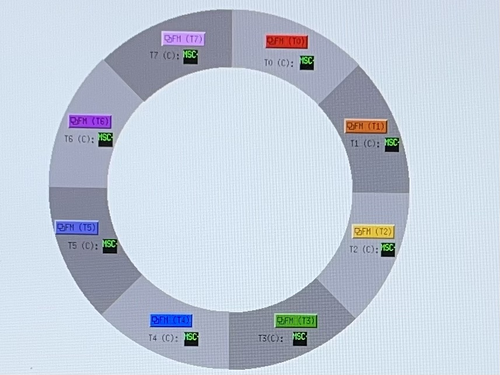

shane | Update | CDS | frosti MEDM screen update |

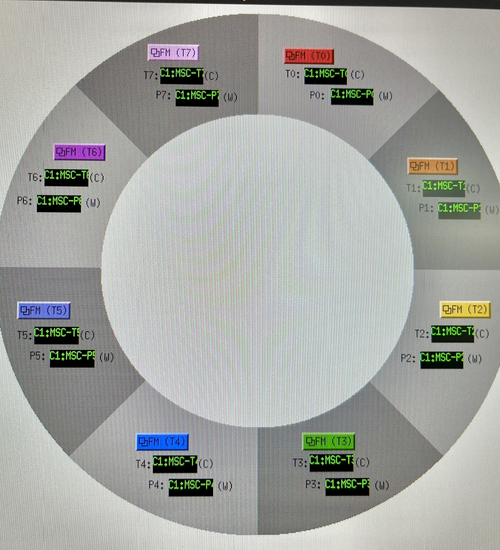

| [Luis, Shane]

Here is the updated MEDM screen, with new orientation and updated labeling to reflect the actual positions of the heater elements. Note that indices start at T0 to be consistent with simulink model, though in the previous elog for the FROSTI layout the heater elements are labeled 1-8.

Also, we finally learned how to take a screenshot on debian. |

| Attachment 1: FROSTIMEDMMay7.2024.png

|

|

|

364

|

Thu May 2 22:43:36 2024 |

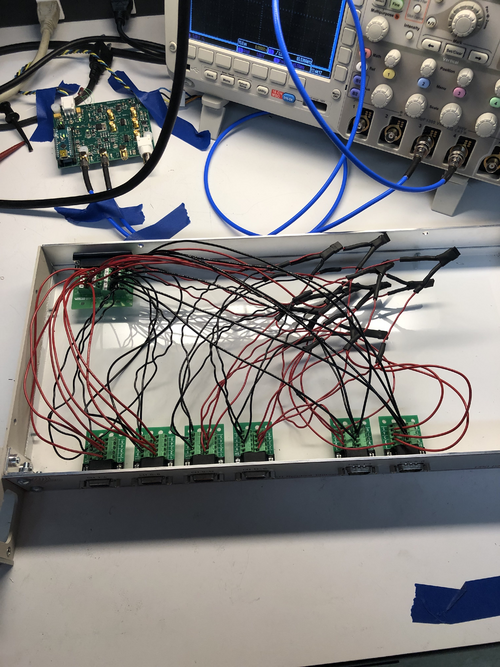

Tyler | Update | Electronics | RTD Readout Chassis Redesign |

| [Tyler, Jon]

Today the FROSTI RTD readout chassis underwent a redesign:

Instead of the original ratiometric method, which involved wiring the FROSTI RTDs in series, each element is individually powered by separate excitations. Each element additionally possesses its own reference resistor of 100 Ohm. Now, if an RTD experiences an electrical short, it should not affect the measurements of the others in sequence, as it had with the original design.

|

| Attachment 1: IMG_9013.jpg

|

|

|

363

|

Mon Apr 22 15:06:33 2024 |

Cynthia | Update | Interferometer Simulations | cavity scan update |

| [Cynthia,Pooyan]

Completed some simulations injecting 0-10th order modes. Some graphs will be used for the poster after some further titles, axis, and range adjustments. |

| Attachment 1: LIGO_4_22.pdf

|

|

|

362

|

Wed Apr 17 15:07:04 2024 |

Shane | Update | Cleanroom | Cleanroom cleaning and particle count |

|

[Mohak, Luke, Luis, Shane, Cynthia, Michael, Xuesi]

cleaning cleanroom and particle count

NOTE: particle counter was found dead, with the charging dock unplugged. For future reference, if you need to unplug the dock, please either plug it back in when you're done, or make a note in an elog so someone else can come down and charge it.

- 1:07 pm: ran zero count test on particle counter

- 1:26 pm: started particle count

- zone 3:

- 0.3 u:1787

- 0.5 u:457

- 1.0 u:41

- zone 4: We were only able to charge the particle counter a small amount before starting the cleaning, so it died again halfway through this measurement, and we didn't get results for zone 4. In interest of time, we just put it on the charger and started the cleaning.

- 1:49 pm: began surface check and wipedown, including softwalls

- 2:16 pm: started vacuuming the floor

- 2:24 pm: finished vacuuming the floor

- 2:26 pm: started mopping the floor

- 2:32 pm: finished mopping the floor

- 2:32 pm: started cleaning the buckets

- 2:35 pm: started mopping with IPA wipes

- 2:43 pm: finished mopping with IPA wipes

- 2:43 pm: changed sticky floor mats

- 2:45 pm: started particle count

- zone 3:

- 0.3 u: 1288

- 0.5 u: 124

- 1.0 u: 0

- zone 4:

- 0.3 u: 415

- 0.5 u: 290

- 1.0 u: 0

|

|

361

|

Mon Apr 15 15:25:10 2024 |

Cynthia | Update | Interferometer Simulations | progress on simulation so far |

|

| Attachment 1: LIGO_update_week3_(2).pdf

|

.png)

|

|

360

|

Mon Apr 15 11:51:03 2024 |

Peter | Update | VLC Update | VLC |

| An update on the VLC project is attached below: |

| Attachment 1: VLC_Update_April_15_2024.pdf

|

|

|

359

|

Mon Apr 8 14:57:41 2024 |

Cynthia, Pooyan | Update | Interferometer Simulations | performed cavity scans for O4 O5, and coupled cavity |

|

| Attachment 1: LIGO_update_week1.pdf

|

|

|

358

|

Mon Apr 8 14:43:29 2024 |

Pooyan | Update | Interferometer Simulations | SIS update single and coupled cavities |

| [Pooyan, Cynthia]

Attached is a brief recap PDF file. A video file showing separate HOMs plots for the cavity scan with ETM08 surface map is also attached.

The codes are available at https://git.ligo.org/uc_riverside/hom-rh/-/tree/main/SIS |

| Attachment 1: IFOSim_SIS__update_4_8_24.pdf

|

|

| Attachment 2: Screen_Recording_2024-03-31_at_2.46.29_AM.mov

|

|

357

|

Sun Apr 7 13:42:51 2024 |

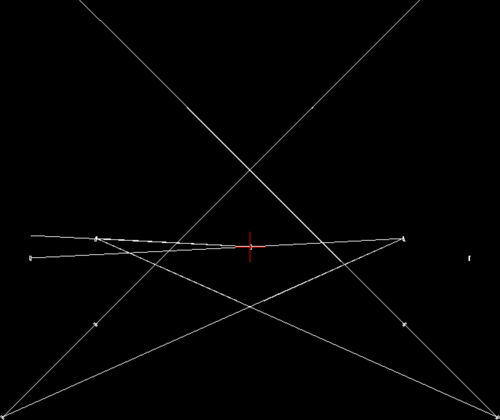

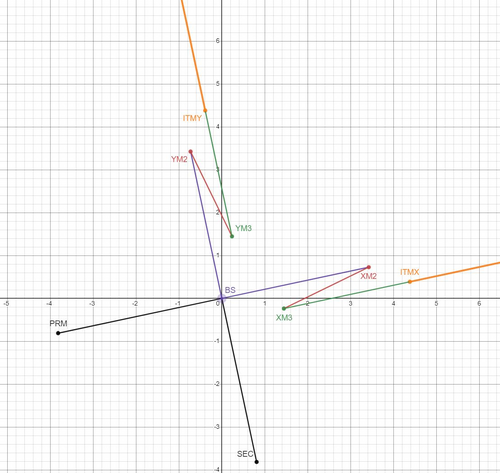

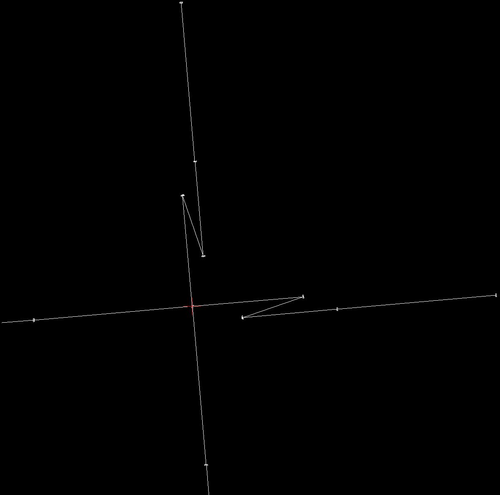

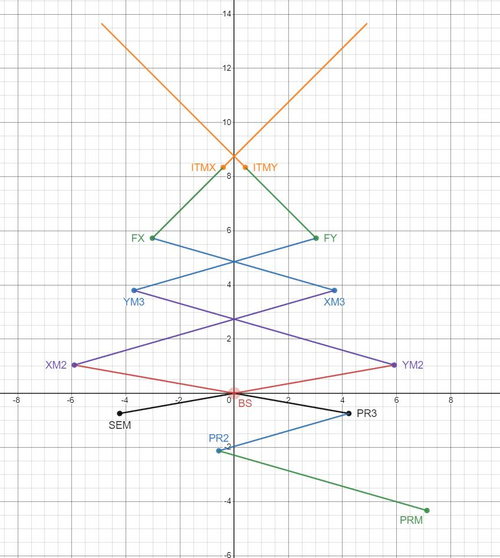

Michael | Update | Interferometer Simulations | Update on status of gtrace project |

| [Pooyan, Michael]

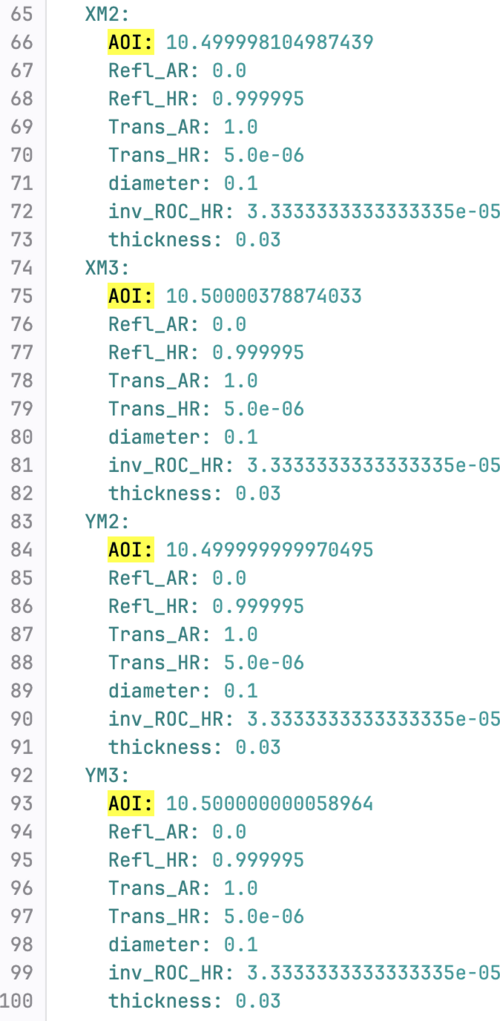

After meeting and discussing the current state of our work with Prof. Fulda a few weeks ago, we have decided that the best next step for the gtrace project is its integration into finesse work. Our first step towards this integration involved creating a sequential beam trace in contrast to the previous non sequential gtrace simulations. A sequential beam trace not only allows for faster runtimes of the simulation (<1 second) but also allows for more direct reading of certain beam parameters (beam size, gouy phase, and angle of incidence). The sequential model was created alongside a yaml output which provides values of parameters, now including the angle of incidence on a mirror.

Last Monday, Pooyan gave a report to the Cosmic Explorer optical design team on the current state of our project and the ultimate goal of our work. During the same meeting another group working in the optical design team presented their own work with gtrace and optical design, focusing more on optimization of parameters based on desired beam sizes at each mirror. It might be a good idea to begin attempting to bring our individual projects together to allow for collaboration and further developments.

Currently, only the crab1 layout has a sequential trace model. Pooyan is currently working on creating a finesse model for crab1 to serve as a proof of concept for how gtrace could be integrated with finesse by providing useful values such as angles of incidence. |

| Attachment 1: Sequential_beam_trace_crab1.png

|

|

| Attachment 2: angle_of_incidence_yaml_example.png

|

|

|

356

|

Wed Mar 27 00:03:57 2024 |

Pooyan | Update | Computers | Chimay relocation to Physics 1129 |

[Jon, Pooyan]

Moved Chimay from the server rack in Physics 1119 to a new rack in Physics 1129. It is connected to the switch in that rack and has the same ip address as before.

All services are up and running.

It appears that JupyterHub creates some processes whenever a user connects to an instance of it, but in some cases does not stop those processes after the user is not using that instance. This results in having lots of running idle processes, each using a small bit of the resources. Those processes are killed now as a result of rebooting. It might be a good idea to manually restart JupyterHub (or the whole machine) every few months to avoid this. |

| Attachment 1: Chima_front.jpg

|

|

| Attachment 2: Chimay_back.jpg

|

|

|

355

|

Tue Mar 26 13:51:56 2024 |

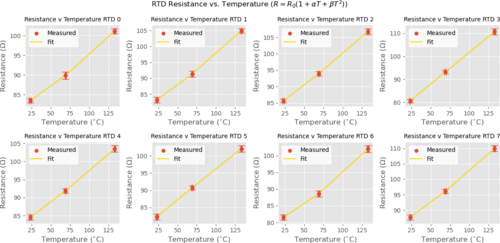

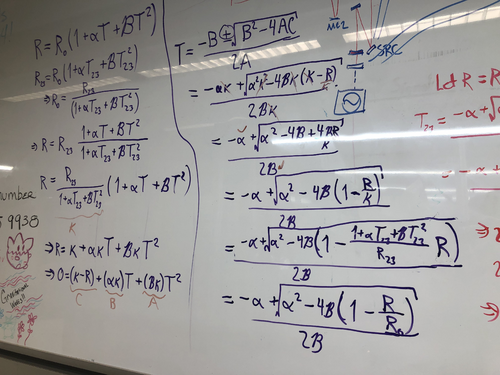

Tyler | Update | DAQ | RTD Parameter Calibration |

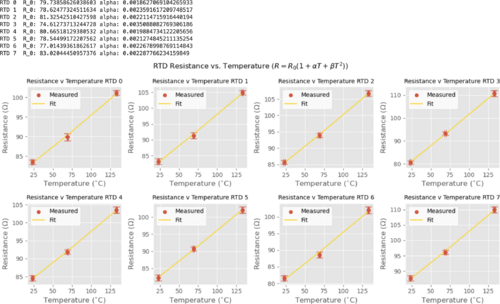

Another re-fit, but this time the quadratic coefficient (beta) is set to 1.003e-6:

R_0 (ohm) Alpha (1/C)

RTD 0 79.7386 0.001863

RTD 1 78.6248 0.002359

RTD 2 81.3254 0.002211

RTD 3 74.6127 0.003509

RTD 4 80.6652 0.001988

RTD 5 78.5450 0.002127

RTD 6 77.0144 0.002268

RTD 7 83.0204 0.002288

| Quote: |

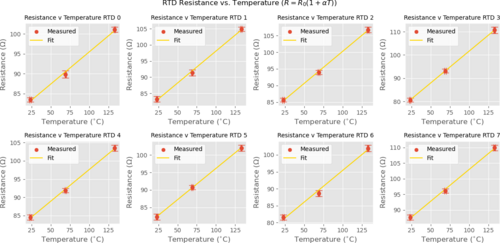

| Refitted RTD calibration, neglecting quadratic term:

R_0 (ohm) Alpha (1/C)

RTD 0 79.3962 0.002031

RTD 1 78.2874 0.002530

RTD 2 80.9775 0.002381

RTD 3 74.2947 0.003684

RTD 4 80.3199 0.002157

RTD 5 78.2106 0.002297

RTD 6 76.6825 0.002438

RTD 7 82.6645 0.002458

Measurements taken can be found here. An uncertainty of 1 C was assumed for temperature.

| Quote: |

| [Jon,Tyler]

We noticed that the RTD temperature readings given on the Cymac were off, and traced the issue to miscalibration in the relationship between the resistance and temperature of each RTD (Callendar-Van Dusen eqn). Below is the table of values inferred from independent measurements of temperature and resistance to rectify this problem. This data was then fitted to better determine the coefficients present in the temperature-resistance relation:

R_0 (ohm) Alpha Beta

RTD 0 80.8674 0.001315 4.273e-6

RTD 1 79.5704 0.001887 3.7873e-6

RTD 2 81.7334 0.002014 2.1724e-6

RTD 3 74.3060 0.003677 3.6022e-8

RTD 4 81.1350 0.001761 2.3598e-6

RTD 5 77.9610 0.002423 -7.5192e-7

RTD 6 78.7980 0.001373 6.2909e-6

RTD 7 83.8616 0.001890 3.3529e-6 |

† |

† |

| Attachment 1: Screenshot_2024-03-26_at_1.23.27_PM.png

|

|

|

354

|

Mon Mar 25 10:55:33 2024 |

Tyler | Update | DAQ | RTD Parameter Calibration |

| Refitted RTD calibration, neglecting quadratic term:

R_0 (ohm) Alpha (1/C)

RTD 0 79.3962 0.002031

RTD 1 78.2874 0.002530

RTD 2 80.9775 0.002381

RTD 3 74.2947 0.003684

RTD 4 80.3199 0.002157

RTD 5 78.2106 0.002297

RTD 6 76.6825 0.002438

RTD 7 82.6645 0.002458

Measurements taken can be found here. An uncertainty of 1 C was assumed for temperature.

| Quote: |

| [Jon,Tyler]

We noticed that the RTD temperature readings given on the Cymac were off, and traced the issue to miscalibration in the relationship between the resistance and temperature of each RTD (Callendar-Van Dusen eqn). Below is the table of values inferred from independent measurements of temperature and resistance to rectify this problem. This data was then fitted to better determine the coefficients present in the temperature-resistance relation:

R_0 (ohm) Alpha Beta

RTD 0 80.8674 0.001315 4.273e-6

RTD 1 79.5704 0.001887 3.7873e-6

RTD 2 81.7334 0.002014 2.1724e-6

RTD 3 74.3060 0.003677 3.6022e-8

RTD 4 81.1350 0.001761 2.3598e-6

RTD 5 77.9610 0.002423 -7.5192e-7

RTD 6 78.7980 0.001373 6.2909e-6

RTD 7 83.8616 0.001890 3.3529e-6 |

† |

| Attachment 1: RTD_Calib_nobeta.png

|

|

|

353

|

Sun Mar 24 11:50:37 2024 |

Aiden | Update | Clean & Bake | Cal Tech FROSTI Parts |

| Bagged the FROSTI legs and feet after the conclusion of the clean and bake. They are double bagged and sitting in the flow bench. |

|

352

|

Sun Mar 24 11:49:27 2024 |

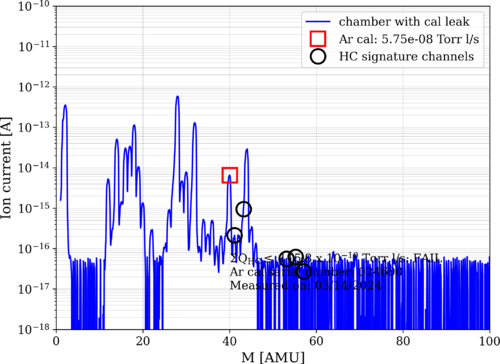

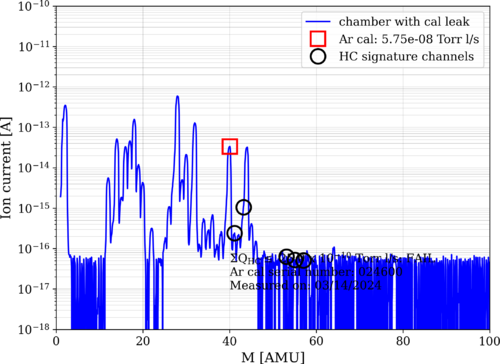

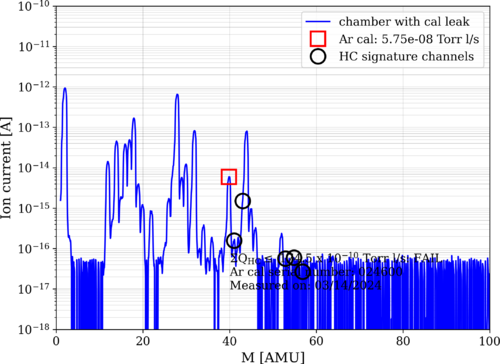

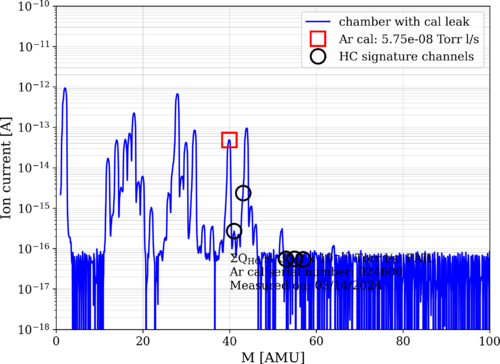

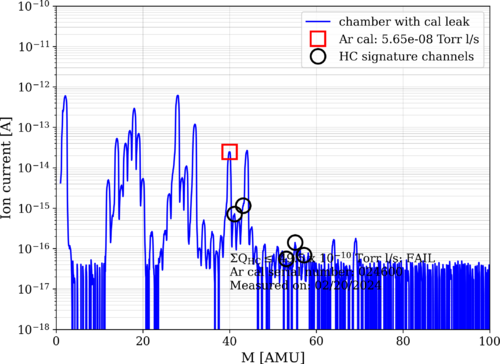

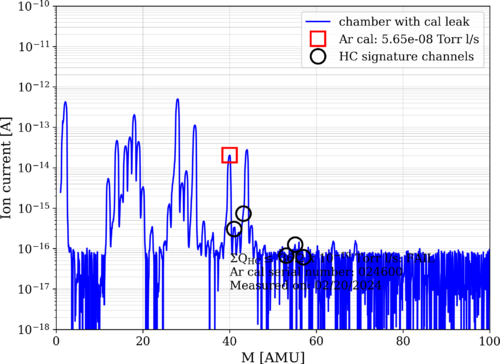

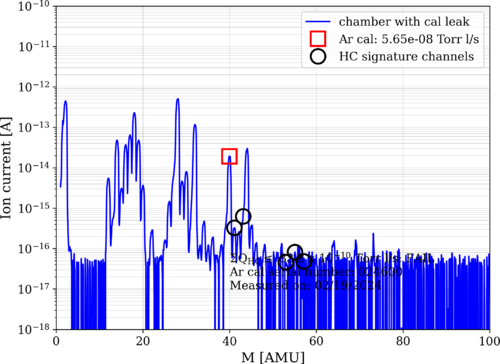

Aiden | Update | General | FROSTI RGA Scan |

| Took RGA data 1 day after the conclusion of Bake 13. Bake 13 ended on Saturday March 23, the RGA data shown was taken on Sunday March 24. The scan shows that the FROSTI is very clean with no outgassing. The HC levels are at 25 e-10. The pressure in the chamber was also a 1.64 e-8 Torr. |

| Attachment 1: bake13_240324_FROSTI_ArC.png

|

|

| Attachment 2: bake13_240324_FROSTI_ArO.png

|

|

|

351

|

Thu Mar 21 16:56:42 2024 |

Tyler | Update | DAQ | RTD Parameter Calibration |

| [Jon,Tyler]

We noticed that the RTD temperature readings given on the Cymac were off, and traced the issue to miscalibration in the relationship between the resistance and temperature of each RTD (Callendar-Van Dusen eqn). Below is the table of values inferred from independent measurements of temperature and resistance to rectify this problem. This data was then fitted to better determine the coefficients present in the temperature-resistance relation:

R_0 (ohm) Alpha Beta

RTD 0 80.8674 0.001315 4.273e-6

RTD 1 79.5704 0.001887 3.7873e-6

RTD 2 81.7334 0.002014 2.1724e-6

RTD 3 74.3060 0.003677 3.6022e-8

RTD 4 81.1350 0.001761 2.3598e-6

RTD 5 77.9610 0.002423 -7.5192e-7

RTD 6 78.7980 0.001373 6.2909e-6

RTD 7 83.8616 0.001890 3.3529e-6 |

| Attachment 1: RTD_Calib-2.png

|

|

| Attachment 2: IMG_8569.jpg

|

|

|

350

|

Tue Mar 19 15:22:27 2024 |

Aiden | Update | Clean & Bake | FROSTI Legs Clean and Bake |

| [Aiden, Luke]

Cleaned and baked the Cal Tech FROSTI legs and showed Luke the procedure on how to clean parts. |

|

349

|

Tue Mar 19 10:55:30 2024 |

Tyler | Update | FLIR | In-Air Optical Test |

| Below is an image I took using the FLIR just before leaving for the LVK meeting. The profile is roughly what we would expect (annular). Any distortions seen are likely from the screen not being completely parallel to the plane of the FroSTI (i.e. the screen slightly bends in various locations). Next step: In-vacuum test at CIT. |

| Attachment 1: FroSTI_Thermal_Profile.png

|

|

|

348

|

Fri Mar 15 16:58:55 2024 |

Aiden | Update | VAC | Vacuum Chamber Frosti Testing |

| [Luke, Luis, Aiden]

On Thursday, March 14 - Took preliminary RGA scans of the empty chamber to compare later on. Vented the chamber and placed the FROSTI into the chamber. Plugged in the DB-25 connectors into the feed through port and checked the connection to make sure there were no shorts before closing the chamber and starting the pumps again.

On Friday, March 15 - The pressure in the chamber has come down to 7 e-6 torr. It seems to be coming down much slower despite the little time the chamber was left open for. This may be due to the FROSTI being out on the table for so long and a bake may be needed to bring the pressure down to near UHV. |

| Attachment 1: bake12_240314_Empty_ArC.png

|

|

| Attachment 2: bake12_240314_Empty_ArO.png

|

|

|

347

|

Wed Mar 6 09:57:52 2024 |

Tyler | Update | TCS | FROSTI Wiring |

Upon finishing the FROSTI assembly last week, we ran into some electrical issues. An electrical short was found between two of the d-sub pins (2 and 8). It appears that the pins were somehow coming into contact with the aluminum surrounding them. This was causing the power supply to trip. The issue was seemingly fixed by adjusting the positioning of the cabling leading out of the reflector. When handling the device in the future, please make sure to keep the wiring as undisturbed as possible. The setup is rather fragile, and moving the cabling around could potentially reintroduce a short like this. |

|

346

|

Thu Feb 29 17:16:48 2024 |

Shane | Update | CDS | MEDM screen for FROSTI T/P readouts |

| Here's the latest draft of the MEDM screen for the FROSTI temp and power readouts, now with a button linking to the c1msc file display. Size/color/label are all changeable, if adjustment is needed. Checked in execute mode as well, and it's working correctly. Also noticed that the MEDM file name has been changed to FROSTI.adl, which I'm noting here for future reference. Still in medm_sandbox directory. |

| Attachment 1: IMG_6259.jpeg

|

|

|

345

|

Wed Feb 28 17:49:18 2024 |

Tyler | Update | TCS | FROSTI Assembly - Days 2-3 |

| [Aiden, Jon, Luis, Luke, Michael, Tyler]

FROSTI assembly was completed today. The RTD and power wires were terminated at the DB-25 connectors and the legs were put on. It is currently placed in front of the stand-in test mass (~5 cm away). The FLIR has also been moved back to it's nominal position. As of now, it appears there are some shorts within the power cabling. This will be a focus of tomorrow's work.

| Quote: |

| [Jon, Tyler, Luis, Luke, Mohak, Cynthia, Michael, Aiden]

FROSTI assembly began today. After a final set of RGA scans were taken, the vacuum chamber was vented and the reflectors were removed. The chamber was then resealed and pumped down again.

Today we completed the installation of the Macor hardware and heater elements between the two reflector halves. Tomorrow we will route, bundle, and terminate the power and sensor cables. |

† |

| Attachment 1: IMG_0947.png

|

|

| Attachment 2: IMG_0956.png

|

|

| Attachment 3: IMG_0957.png

|

|

| Attachment 4: IMG_0959.png

|

|

|

344

|

Wed Feb 28 12:02:08 2024 |

Tyler | Update | General | Resistors for Heater Elements Update |

| Power Res (Ohm) RTD Res (Ohm)

Heater 1= 72.8; 80.6

Heater 2= 69.5; 80.8

Heater 3= 70; 83.2

Heater 4= 70.6; 78.7

Heater 5= 69.9; 80.6

Heater 6= 71.1; 78.2

Heater 7= 68.5; 76.8

Heater 8= 70.1; 82.8

| Quote: |

| Power Res (Ohm) RTD Res (Ohm)

Heater 1= 73.6; 81.8

Heater 2= 70.4; 82.1

Heater 3= 71; 84.5

Heater 4= 71.5; 80

Heater 5= 70.5; 81.7

Heater 6= 72; 79.4

Heater 7= 69.2; 78.2

Heater 8= 71.1; 84.2 |

† |

|

343

|

Tue Feb 27 09:06:29 2024 |

Cynthia | Update | Interferometer Simulations | cavity scan with higher order input laser |

| I performed a few cavity scan with the inputing laser with a different mode (not pure 00). For each laser I included a graph for just plotting the order with highest power (for example 1st order laser input the first plot only scanned for 1st order in that cavity), and I have also included a graph scanning for order 1-10. |

| Attachment 1: ligoPre_2_27.pdf

|

|

|

342

|

Tue Feb 27 03:26:28 2024 |

Michael | Update | Interferometer Simulations | Reverse aLIGO Layout Created in Gtrace |

| I've created the simulation for reverse aLIGO layout in gtrace. Attached are the desmos model and the output dxf file. From here Pooyan and I plan to create a brief report of our progress to the CE optical design group. |

| Attachment 1: reverse_aligo_desmos.JPG

|

|

| Attachment 2: reverse_aligo_dxf.JPG

|

|

|

341

|

Mon Feb 26 21:23:27 2024 |

Jon | Update | TCS | FROSTI Assembly - Day 1 |

| [Jon, Tyler, Luis, Luke, Mohak, Cynthia, Michael, Aiden]

FROSTI assembly began today. After a final set of RGA scans were taken, the vacuum chamber was vented and the reflectors were removed. The chamber was then resealed and pumped down again.

Today we completed the installation of the Macor hardware and heater elements between the two reflector halves. Tomorrow we will route, bundle, and terminate the power and sensor cables. |

| Attachment 1: IMG-20240226-WA0008.jpg

|

|

| Attachment 2: IMG-20240226-WA0006.jpg

|

|

| Attachment 3: IMG-20240226-WA0011.jpg

|

|

| Attachment 4: IMG-20240226-WA0010.jpg

|

|

| Attachment 5: IMG-20240226-WA0012.jpg

|

|

| Attachment 6: IMG_0944.png

|

|

| Attachment 7: IMG_0946.png

|

|

|

340

|

Mon Feb 26 15:15:39 2024 |

Aiden | Update | General | Vacuum Chamber Baking Update |

| Started Bake 12 on Wednesday Feb. 21 and turned the bake off on Saturday Feb. 24. This was a normal low temp bake with the PID controllers set to 110 degC. |

|

339

|

Sat Feb 24 08:53:38 2024 |

Jon | Infrastructure | Computers | Matlab upgraded to 2023b on Chimay |

| I upgraded Matlab on chimay to the latest stable release, 2023b. From some quick tests, it appears to be in working order. Let me know of any issues. |

|

338

|

Fri Feb 23 18:03:27 2024 |

Tyler | Update | FLIR | Optical Test Setup in Cleanroom |

| [Tyler, Xuesi]

The FLIR and test mass stand-in have been transferred into the cleanroom. A software test will be run as soon as we get an ethernet cable long enough to reach into the cleanroom where the camera is set up. Once this is finished, the FLIR will be moved aside for construction of the FROSTI! When completed, the camera will be placed back into position for in-air optical testing.

|

| Attachment 1: IMG_0941.png

|

|

|

337

|

Fri Feb 23 15:01:48 2024 |

Shane | Update | CDS | Latest draft of MEDM screen for FROSTI readouts |

| Here's the latest draft of the MEDM screen for the FrOSTI temp and power readouts. Also, debugged the text readout boxes so they're now correctly reading out the live temperature and power values. |

| Attachment 1: IMG_6128.jpg

|

|

| Attachment 2: 23.jpg

|

|

|

335

|

Thu Feb 22 21:48:16 2024 |

Jon | Update | VAC | Vacuum vent for RGA testing of reflector |

[Jon, Tyler, Luke, Aiden]

Summary

Following Wednesday's cleanroom cleaning [333], we proceeded to vent the vacuum chamber, remove the heater elements and their mount structure, and install the FROSTI reflectors. The reflectors are the final components to undergo RGA testing before the FROSTI prototype can be assembled. After installing the reflectors, we pumped the chamber back down and initiated a 48-hour 125 C bake.

Vacuum Vent

At ~1:00 pm, we shut off power to all eight of the FROSTI heater elements. Prior to shutoff, all were operating in vacuum at roughly 300 C. We then waited approximately 30 minutes for the elements' temperatures to fall below 50 C.

At this point, we isolated the RGA volume from the main volume by closing both gate valves, leaving the RGA volume to continue to be pumped through the bypass line. We then backfilled the main volume via the needle valve connected to one of the 2.75" ports. Once the pressures had equalized, we removed the chamber lid via our usual procedure (requiring only a small amount of flathead-screwdriver prying) and extracted the heater element assembly.

Reflector Assembly

We then removed the FROSTI reflectors from their protective packaging (for the very first time) on the cleanroom tabletop. We tested the fit of the Macor and stainless steel hardware in the reflectors' tapped holes. The Macor standoffs and bolts appear to fit perfectly. However, the 1/4-20 tapped holes for joining the two reflector halves are too shallow by ~1/4". As a temporary fix, we used some on-hand stainless steel washers (which had already been cleaned and baked) to securely fasten the two halves together. In the final assembly we will replace these with slightly shorter 1/4-20 vented bolts.

Pumpdown and Bake

The two fastened reflector halves were placed inside the chamber, sitting on top of the two mounting legs (see attached photos). We then reinstalled the lid. In order to rough the main volume, we isolated the RGA volume from the pumpline (by closing the bypass line valve), shut down the pumps, and then backfilled the pumpline via the manual vent valve on the turbo pump.

Once the pressures had equalized, we opened the 6" gate valve separating the pumpline from the main volume and powered on the roughing pump. Once the main volume pressure fell below 0.5 Torr, we powered on the turbo pump as well. The main volume pressure reached 5e-6 Torr within ~30 minutes, consistent with previous experience, and was continuing to slowly fall.

Lastly, we initiated a 125 C bake-out of the entire system following our usual procedure. We plan to run this bake for 48 hours (i.e., through the end of the day Friday). |

| Attachment 1: IMG_0938.png

|

|

| Attachment 2: IMG_0939.png

|

|

|

334

|

Wed Feb 21 23:15:07 2024 |

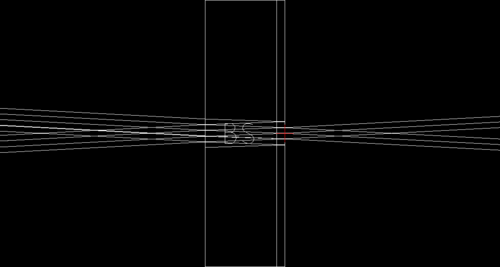

Michael | Update | Interferometer Simulations | Long Shoelaces 1 Layout Created in Gtrace and Fixed Ghosting in Beamsplitter |

| I have created the long shoelaces 1 layout for cosmic explorer using gtrace, a slight modification from the shoelaces 1 layout design. I also modified the simulation code slightly to remove ghosting effects in the beamsplitter. Originally the python code specified that the HR and AR sides of the beamsplitter both have the same transmission/reflection. I modified this to the ideal case of: Refl_AR = 0, Trans_AR = 1. I have attached two images below to show the before and after effect of this modification. |

| Attachment 1: long_shoelaces1_desmos.JPG

|

|

| Attachment 2: AR_side_with_reflection.PNG

|

|

| Attachment 3: AR_side_without_reflection.PNG

|

|

|

333

|

Wed Feb 21 11:58:30 2024 |

Shane | Update | Cleanroom | cleanroom cleaning and particle count |

|

[Luke, Shane, Tyler]

cleaning cleanroom and particle count

- 11:50 am: ran zero count test on particle counter

- 11:55 am: started particle count

- zone 3:

- 0.3 u: 1787

- 0.5 u: 581

- 1.0 u: 166

- zone 4:

- 0.3 u: 623

- 0.5 u: 290

- 1.0 u: 124

- 12:17 pm: began surface check and wipedown, including softwalls

- 12:25 pm: started vacuuming the floor

- 12:36 pm: finished vacuuming the floor

- 12:44 pm: started mopping the floor

- 12:57 pm: finished mopping the floor

- 12:58 pm: started cleaning the buckets

- 12:59 pm: started mopping with IPA wipes

- 1:05 pm: finished mopping with IPA wipes

- 1:06 pm: changed sticky floor mats

- 1:08 pm: started particle count

- zone 3:

- 0.3 u: 1621

- 0.5 u: 581

- 1.0 u: 332

- zone 4:

- 0.3 u: 1080

- 0.5 u: 457

- 1.0 u: 249

|

|

332

|

Tue Feb 20 18:08:24 2024 |

Aiden | Update | General | Degassing the RGA |

| I took an RGA measurement before and after degassing the RGA. Both data was taken with the Argon open. The pressure before taking data was 2.39 e-8 torr in the main volume. Note that the main chamber was fully valved off for the degas and the main chamber pressure quickly rose to e-6 torr. Further investigation of this rise should be done as this might be the main culprit for the leaking. |

| Attachment 1: bake11_240220_Elements_postdegas_ArO.png

|

|

| Attachment 2: bake11_240220_Elements_predegas_ArO.png

|

|

|

331

|

Tue Feb 20 11:31:49 2024 |

Tyler | Update | Cleanroom | Garment Cabinet Door Replacement |

| [Luis, Luke, Pooyan, Tyler]

The replacement door for the HEPA garment cabinet arrived last week, and was installed on Thursday. However, it looks like there's a small gap between the door and where the hinge is attached to the cabinet frame. No screws were provided with the replacement door. If we want to perform any adjustments, we have to be very careful; the screws break very easily.

|

| Attachment 1: image_67190529.JPG

|

|

| Attachment 2: image_67177473.JPG

|

|

|

330

|

Tue Feb 20 08:01:30 2024 |

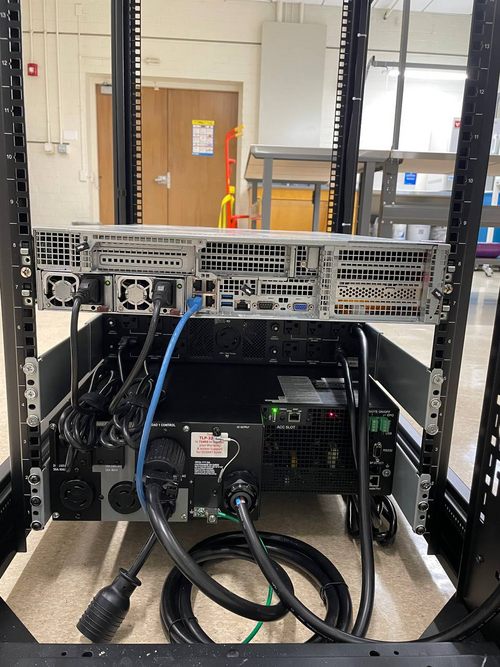

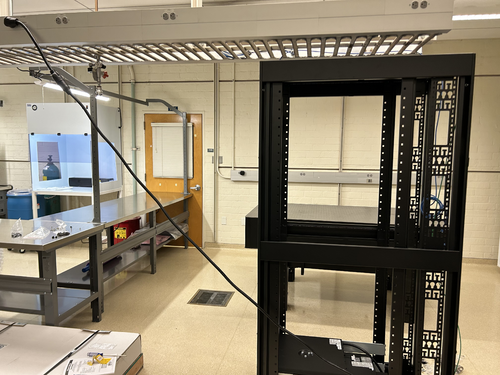

Jon | Infrastructure | General | Power and network equipment installed in 1129 rack |

| [Jon, Tyler, Pooyan, Luis, Luke, Peter]

On Thursday we installed the power conditioning/distribution equipment and networking equipment in the new 1129 rack. The hardware is identical to the setup in the 1119 rack and includes:

- Tripp Lite SU5KRT3UTF - 208V, 5kVA on-line UPS with 120V transformer

- CyberPower PDU20M2F12R - metered power distribution unit, (14) NEMA 5-20R

- Ubiquiti USW-Pro-48 - 48 port 10Gbps network switch

The UPS is connected to a 208V NEMA 6-30R outlet in the overhead cable tray, which is on the building's "standby" (backup power) circuit. An 8-ft L6-30 extension cord has been ordered to permanently run the power cable through the cable tray.

The network switch will be connected to a Cat6 cable that was recently run by ITS from the 1119 rack, allowing the lab's LAN to be extended into 1129. This Ethernet link remains to be tested.

| Quote: |

Server Rack Installation

A new Tripp Lite 42U open-frame rack was laid in place in 1129 and anchored to the floor (see attachment 1). This rack will house all of our general-purpose and simulation computers, which will be relocated from the 1119 rack at a later time.

|

|

| Attachment 1: IMG_0924.jpeg

|

|

| Attachment 2: IMG_0925.jpeg

|

|

| Attachment 3: IMG_0921.jpeg

|

|

| Attachment 4: IMG_0922.jpeg

|

|

|

329

|

Mon Feb 19 14:40:21 2024 |

Shane | Update | CDS | MEDM screen for FROSTI temp readouts |

| Here's the latest draft of the MEDM screen for the FROSTI heating elements' temperature readouts. Note that the MEDM screen isn't actually this grainy, this just happens to be a photo of the lab monitor's screen off a phone. |

| Attachment 1: IMG_6094.jpeg

|

|

| Attachment 2: IMG_6092.jpeg

|

|

|

328

|

Mon Feb 19 14:17:50 2024 |

Aiden | Update | VAC | Heater Element RGA Scan |

| Three days after the completion of Bake 11, the Heater elements RGA scan looks much cleaner. The HC level is back down to 33 e-10 torrl/s with the pressure at 2.13 e-8 torr. I could not take a= scan with the Argon closed as it was left open during the bake and not closed since then. |

| Attachment 1: bake11_240219_Elements_ArO.png

|

|

|

327

|

Fri Feb 16 18:37:28 2024 |

Jon | Update | VAC | Bake ended 6:23 pm |

I ended the bake of the UHV system (that began on Monday) at 6:23 pm today by switching OFF both PID controllers. The heaters elements were run at max power (24 V DC / 200 mA per element) during this bake, and I left them powered at the same level.

At the time, the instrument readings were as follows:

- Left high-limit controller: 138 C

- Right high-limit controller: 128 C

- Left PID controller: 100 C

- Right PID controller: 100 C

- Main volume pressure: 8.17e-7 Torr

- RGA volume pressure: 4.63e-7 Torr

|