| ID |

Date |

Author |

Type |

Category |

Subject |

|

244

|

Mon Oct 23 18:02:23 2023 |

Shane, Jon | Update | CDS | Timing chassis assembly complete |

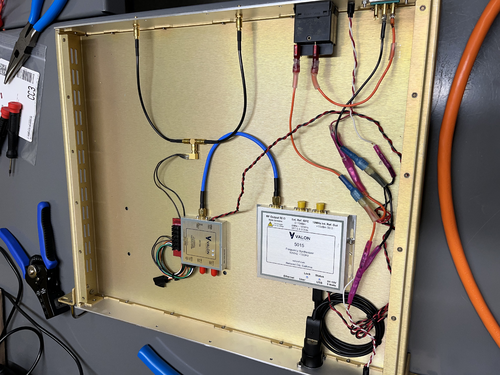

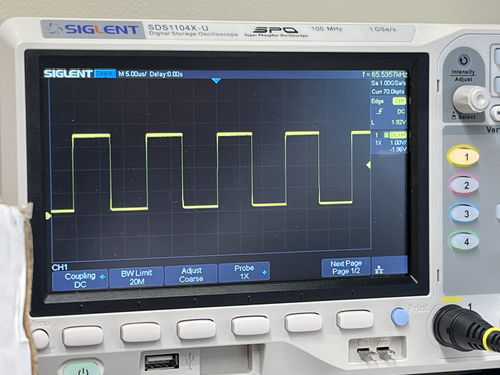

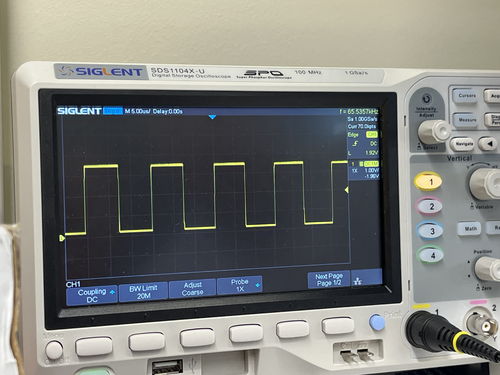

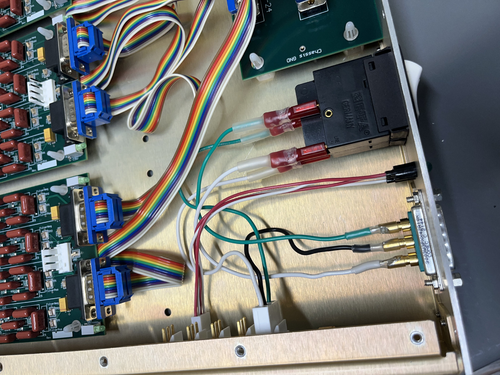

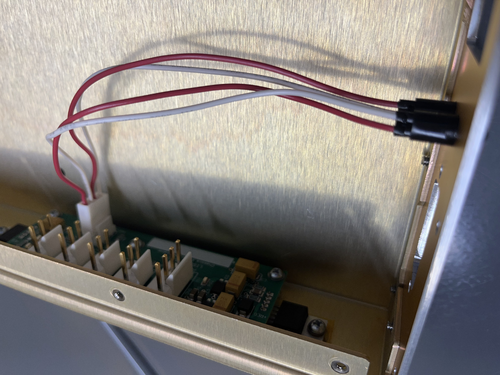

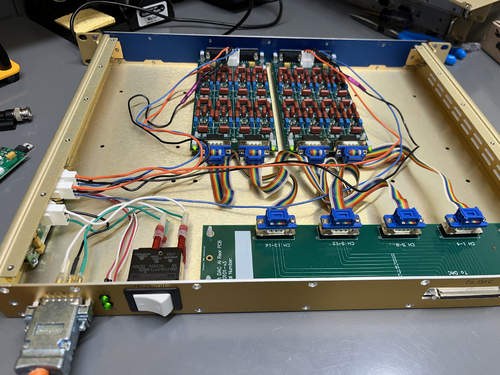

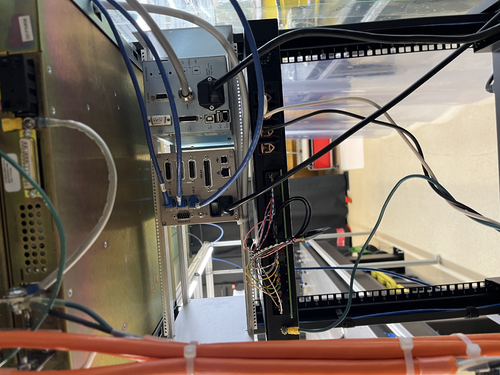

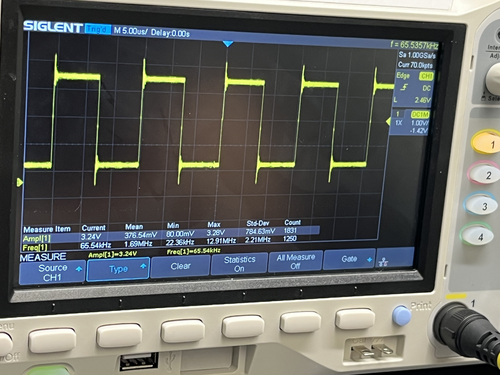

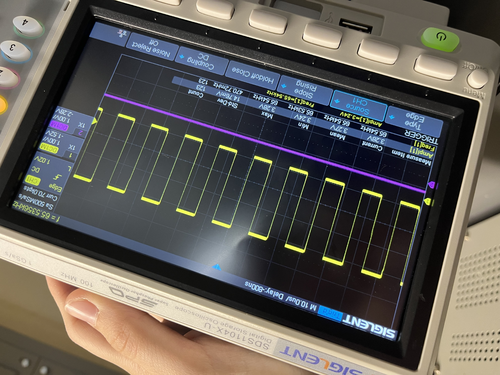

| Concluded assembly of timing chassis for CyMAC today; see attachment 1 for interior set up of chassis. Installed front and rear panels, wired on/off switch and LED assembly, and tested to confirm everything is powering on correctly. Also tested the outputted timing reference that will go to DAC and ADC adapter boards (see attachment 2 for output 1 and attachment 3 for output 2). |

| Attachment 1: timing_chassis_complete.jpeg

|

|

| Attachment 2: timing_chassis_output_1.jpeg

|

|

| Attachment 3: timing_chassis_output_2.jpeg

|

|

|

137

|

Wed Jun 28 15:58:56 2023 |

Shane, Cao | Infrastructure | VAC | Power trip problem remains, source of smoke is insulation |

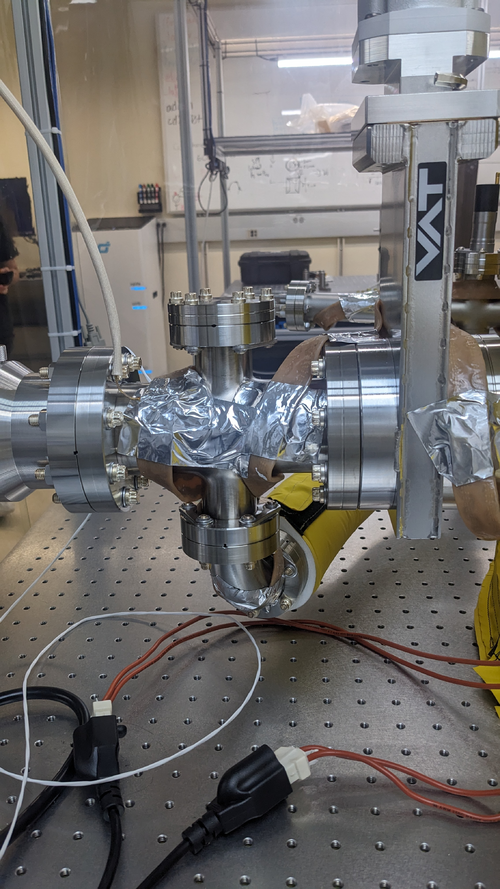

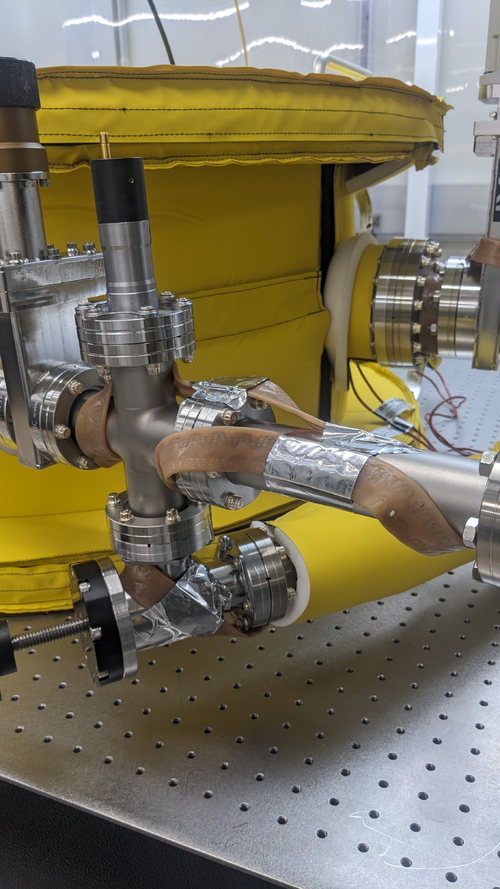

| [Shane, Cao]

With the new change in wiring configuration described in elog 136, we tried to power up the heaters for baking the vacuum chamber again.

Given that we were worried about the turbo pump overheats, we set the setpoints of of bother high temperature controller and PID controller to be 120 deg C before turning the heaters on

1. Evidence of smoke originating from CoolSkin insulation

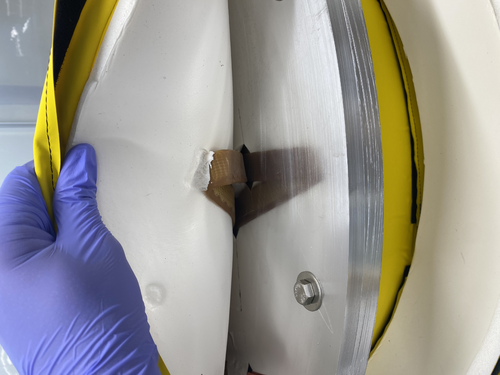

We then removed most of the CoolSkin insulation on the Pump and RGA lines ( apart from the one around the flexible bypass line connecting the two ) (see image Pumpline_afterRemoveInsul and RGAline_afterRemoeInsul) .

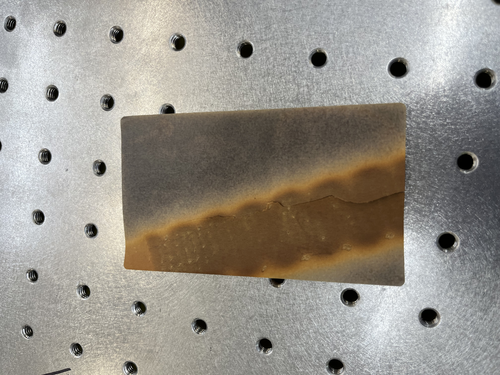

Upon removal of the insulation, we noticed that the insulating foam melted onto the heating tape (see image MeltedInsulation1 and MeltedInsulation2). This is the first indication that the smoke had most likely coming from the insulating foam itself

Once we started baking, upon reaching 80 degree range. We observed no smoke at the location that we removed the insulation. However, We observed smoked coming from underneath the insulation around the flexible pipe, and not from the velcro areas.

What could be causing this, given that the maximum operating temperature of the insulation is 200 deg C? Most likely, the heating tape is much hotter than we think it is. But given that the temperature sensor readout is much lower than 200 deg C, it's likely that this is due to poor thermal contact and it takes a while for sensor to reach a thermal equilibrium with the heating tape. Here, I suggest we should implement the following:

- We should look into usingsome form of thermal tape (if possible to secure the temperature sensors)

- Unfortunately or controller does not allow programming process, we will have to implement manual temperature stepping, emulating ramping process over the first hour, until slowly reach 120 deg C

- OR Tune the PID controller coeffs, especially P and I for longer rise time and settling time

2. The heaters still trip our power

Upon reaching 80 deg C,our main power trip. Unfortunately I don't know how to reset this. Do we need to contact facility on this? Reading elog 136, I noticed that both controllers are connected to the same circuit LP3B 6, which is the same circuit the some of the fan-filters and LED light panels of the cleanroom connected to. From the elog, the circuit has a 20 A limit . An max operation, the 2 heater controllers draw 30 Amps, approx 7 Amps for the fan-filters, and another 1.5 A for LED panel. The combination of these equipment must have overload the circuit and tripped it . Currently half the fans + lights are off in the cleanroom are off due to power trip. Here, I would make a suggestion that each heater controller should be connected to a separate circuit . Currently we LP3B 7 (same side next to LB3B 6) and LB3B 4 (opposite side of the rail) having no equipemts connected to them, but will require cable extensions. |

| Attachment 1: Pumpline_afterRemoveInsul.jpg

|

|

| Attachment 2: RGAline_afterRemoeInsul.jpg

|

|

| Attachment 3: MeltedInsulation1.jpg

|

|

| Attachment 4: MeltedInsulation1.jpg

|

|

| Attachment 5: MeltedInsulation2.jpg

|

|

|

177

|

Fri Jul 28 13:07:39 2023 |

Shane, Aiden | Update | Cleanroom | cleanroom cleaning and particle count |

|

[Aiden, Shane]

cleaning cleanroom and particle count

- 11:08 am: started particle count

- zone 3:

- 0.3 u: 4198

- 0.5 u: 1080

- 1.0 u: 581

- zone 4:

- 0.3 u: 1247

- 0.5 u: 623

- 1.0 u: 415

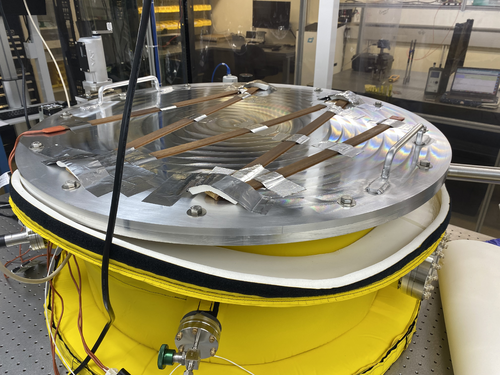

- 11:24 am: break for removal of vac chamber insulation (pictures attached), with counts before removal as seen above, and counts after removal/replacement for zone 3 as follows:

- zone 3:

- 0.3 u: 2993

- 0.5 u: 415

- 1.0 u: 207

- 12:02 pm: began surface check and wipedown

- 12:13 pm: started vacuuming the floor

- 12:25 pm: finished vacuuming the floor

- 12:26 pm: started mopping the floor

- 12:32 pm: finished mopping the floor

- 12:32 pm: started cleaning the buckets

- 12:37 pm: started mopping with IPA wipes

- 12:43 pm: finished mopping with IPA wipes

- 12:45 pm: changed sticky floor mats

- 12:47 pm: started particle count

- zone 3:

- 0.3 u: 2951

- 0.5 u: 290

- 1.0 u: 41

- zone 4:

- 0.3 u: 290

- 0.5 u: 0

- 1.0 u: 0

|

| Attachment 1: image_50412289.JPG

|

|

| Attachment 2: image_50432769.JPG

|

|

| Attachment 3: image_67126017.JPG

|

|

| Attachment 4: image_67163137.JPG

|

|

| Attachment 5: image_67168001.JPG

|

|

| Attachment 6: IMG_8427.jpeg

|

|

|

228

|

Fri Sep 29 11:22:33 2023 |

Shane, Aiden | Update | Cleanroom | cleaning and particle count |

|

[Aiden, Shane]

cleaning cleanroom and particle count

- 10:06 am: ran zero count test on particle counter

- 10:07 am: started particle count

- zone 3:

- 0.3 u: 2203

- 0.5 u: 831

- 1.0 u: 540

- zone 4:

- 0.3 u: 374

- 0.5 u: 124

- 1.0 u: 124

- 10:25 am: began surface check and wipedown

- 10:34 am: started vacuuming the floor

- 10:44 am: finished vacuuming the floor

- 10:45 am: started mopping the floor

- 10:49 am: finished mopping the floor

- 10:50 am: started cleaning the buckets

- 10:57 am: started mopping with IPA wipes

- 11:01 am: finished mopping with IPA wipes

- 11:02 am: changed sticky floor mats

- 11:03 am: started particle count

- zone 3:

- 0.3 u: 2535

- 0.5 u: 374

- 1.0 u: 166

- zone 4:

- 0.3 u: 581

- 0.5 u: 41

- 1.0 u: 0

|

|

241

|

Fri Oct 20 16:38:02 2023 |

Shane, Aiden | Update | Cleanroom | Cleanrooom cleaning and particle count |

|

[Aiden, Shane]

cleaning cleanroom and particle count

|

|

28

|

Sat Feb 11 17:09:29 2023 |

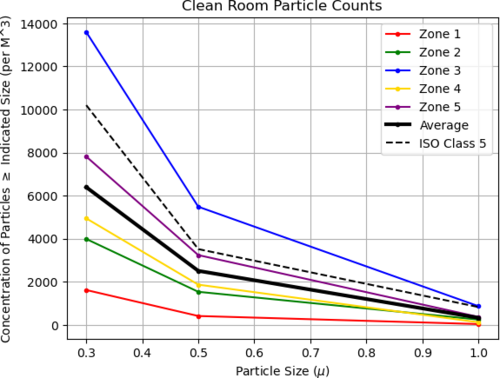

Shane | Update | General | clean room particle counts 2/10/23 |

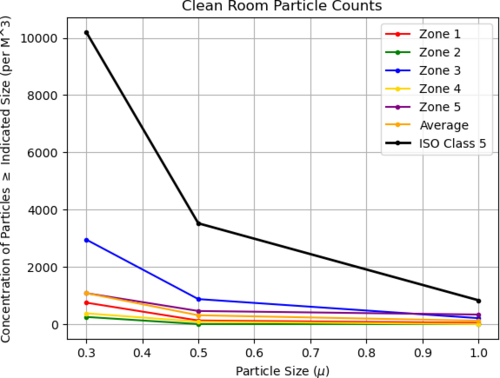

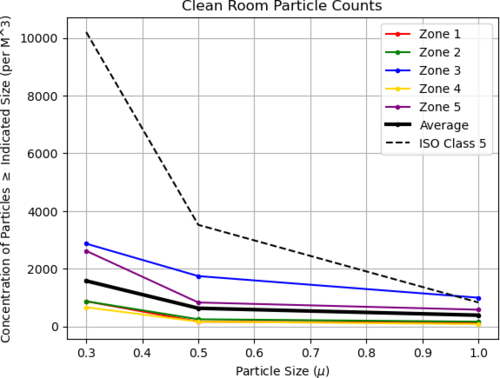

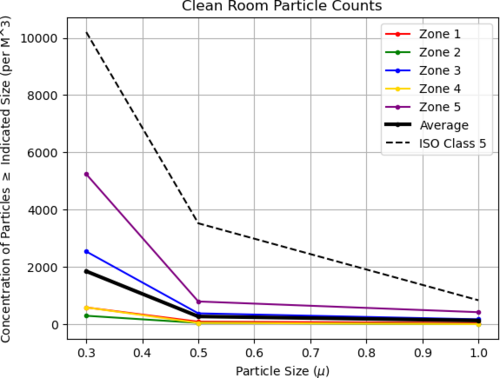

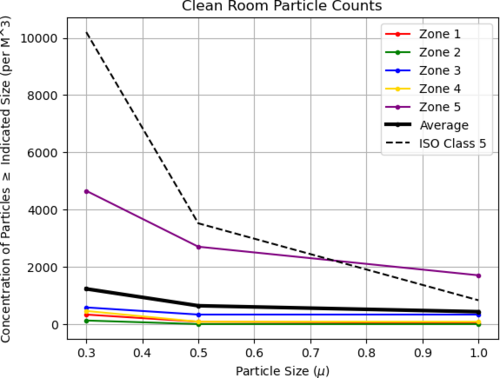

| Took a round of clean room counts after the latest clean of vacuum chamber on Feb 10. Used 60 second sample time, 5 samples for each of the 5 zones. Plots attached for both occupied clean room (one person inside, attachment 1) and unoccupied clean room (empty attachment 2), as well as the raw data from the particle counter (attachment 3). |

| Attachment 1: occupied2.10.23.pdf

|

|

| Attachment 2: unoccupied2.10.23.pdf

|

|

| Attachment 3: particlecounts2.10.23.PDF

|

|

|

32

|

Thu Feb 23 13:32:55 2023 |

Shane | Update | General | Clean room floor particle counts |

| Here are the counts from the clean room floor today. The counts should be dated- the ones from today (2/23/23) are the last 8 in the chart. The first set of 2 measurements from today were under the table by the clean room entrance, the next two were under the table by the vacuum chamber, the next two were on the floor by the vacuum chamber lid, and the last two were on top of the table for comparison. All measurements were taken using 2 minute sample time. |

| Attachment 1: 2.23.2023.pdf

|

|

|

49

|

Thu Mar 9 13:51:42 2023 |

Shane | Update | General | Clean room counts 3/9/23 |

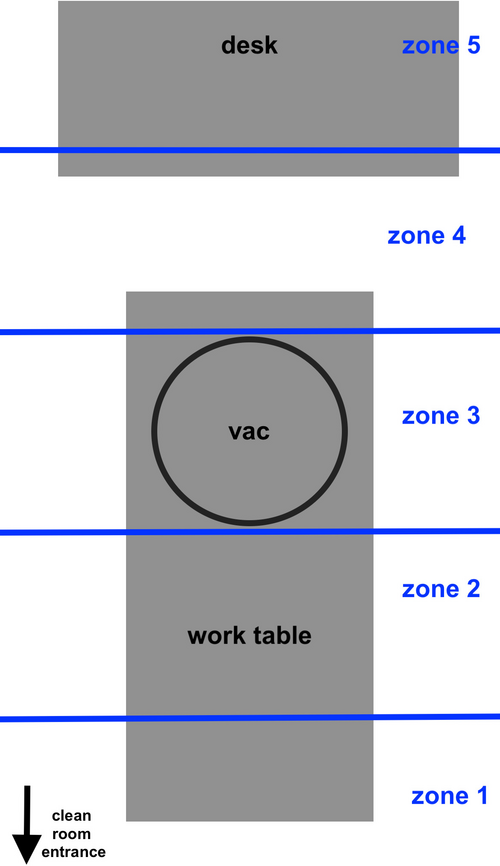

| Here's the clean room counts from this morning. Also attached is rough diagram of where the five zones are in the clean room. Counts taken with 2 minute sample time, three samples in each zone. |

| Attachment 1: particlecounts3.9.23.pdf

|

|

| Attachment 2: clean_room_zones.JPG

|

|

|

54

|

Wed Mar 22 15:25:00 2023 |

Shane | Update | General | Clean room recertification particle counts |

| Attached are the five zone particle measurements for the clean room now that the fan speeds have been set to MEDIUM. 2 min sample time, 3 samples per zone. The occupied clean room measurements were unusual in that they generally got larger towards minute 6 instead of settling and going to zero, and for this reason didn't stay beneath the class 5 requirement at the end of the samples. The unoccupied counts look more similar to what was expected, and generally settle under the class five requirement. |

| Attachment 1: counts3.22.23.pdf

|

|

|

110

|

Wed May 31 12:16:28 2023 |

Shane | Update | Cleanroom | cleanroom particle counts (full 5 zone measurement) |

| Attached is the full 5 zone particle measurement for the cleanroom after this week's cleaning, 5/31/23. |

| Attachment 1: 23.png

|

|

|

133

|

Tue Jun 27 12:09:37 2023 |

Shane | Update | Cleanroom | cleanroom 5 zone particle count measurement |

| Attached is 5 zone measurement for cleanroom particulate count. Zone 3 (in front of vacuum chamber) higher than usual, likely due to recent vac work. Slightly above ISO class 5 standard in 1.0 micron range, measuring 997 particles/cubic meter while ISO standard is 832 particles/cubic meter in this range.

Zero count test on particle counter performed prior to today's measurement. |

| Attachment 1: 23.png

|

|

|

172

|

Tue Jul 25 15:35:14 2023 |

Shane | Update | Electronics | More chassis moved |

| Finished basic assembly of binary input and output chassis today, and moved one to top shelf of work bench. The other is in corner of work bench (image attached). They are delicate, so please do not move them or place anything on top of them. |

| Attachment 1: IMG_8409.HEIC

|

|

182

|

Mon Jul 31 12:39:01 2023 |

Shane | Update | Electronics | LED cable assemblies installed |

| Today I put together the two LED cable assemblies for the CyMAC and mounted them in the anti-aliasing and anti-imaging chassis. |

| Attachment 1: IMG_8514.jpeg

|

|

| Attachment 2: IMG_8516.jpeg

|

|

|

199

|

Wed Aug 9 17:35:26 2023 |

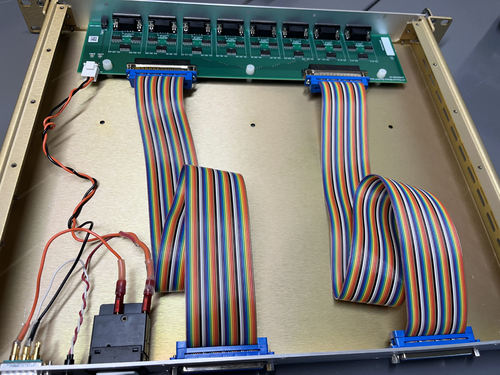

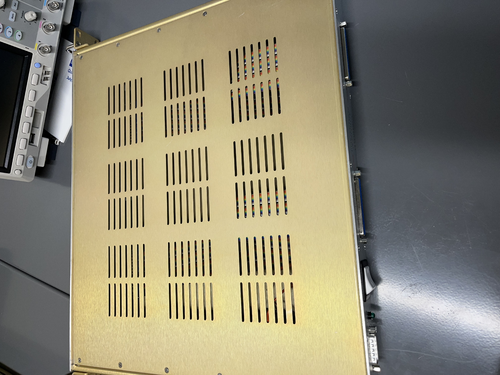

Shane | Update | CDS | Binary output chassis finished |

| Finished the internal wiring for the binary output chassis today, which completes its assembly. Also secured ribbon cables and chassis lid with their respective screws. Note: one of the spade lugs' internal metal piece is a little loose and had to be reinserted after falling out once. Seemed secure after this, and I checked continuity on everything and it was all good. |

| Attachment 1: IMG_8685.jpeg

|

|

| Attachment 2: IMG_8686.jpeg

|

|

|

230

|

Fri Sep 29 11:53:54 2023 |

Shane | Update | Cleanroom | 5 zone particle count measurement in cleanroom |

| Today's 5 zone measurement of cleanroom particulate concentration is attached |

| Attachment 1: 23.png

|

|

| Attachment 2: 23.png

|

|

|

247

|

Fri Oct 27 15:28:30 2023 |

Shane | Update | CDS | AA and AI chassis for CyMAC powered on and functional |

| CyMAC updates: Switched out the faulty power regulator boards in the Anti-Aliasing and Anti-Imaging chassis. Both chassis are now powering up correctly with lights on and the correct voltages in/out of the power regulator board. Images attached. All chassis for the CyMAC now functional, so next step is mounting everything in the rack. |

| Attachment 1: AI_chassis_lights_on.jpeg

|

|

| Attachment 2: AA_chassis_lights_on.jpeg

|

|

|

250

|

Mon Oct 30 18:15:13 2023 |

Shane | Update | CDS | CyMAC chassis mounted and progress on power connections |

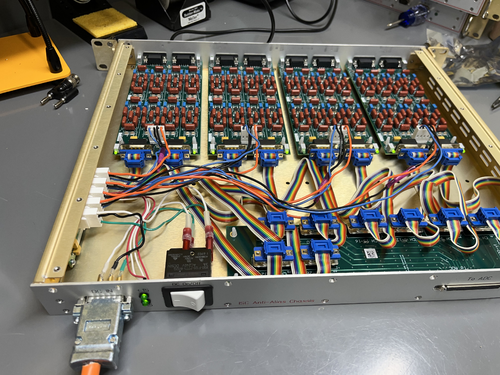

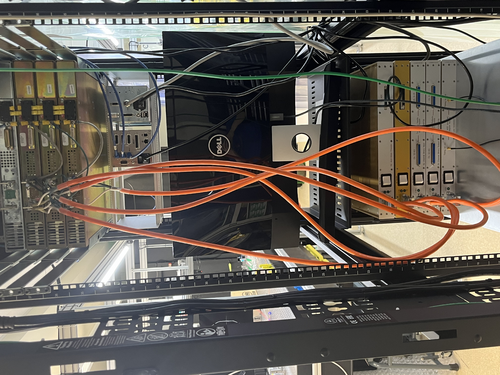

| All CyMAC chassis mounted in electronics rack today, and shelf for monitor also mounted. Images attached. Assembled grounding cables for power connections, and attached the timing chassis to power & gnd. Powered on successfully with correct voltages in expected places. After power test, everything was turned off and unplugged. Next steps: attach grounding cables to other four power supply chassis. Also attach anti-aliasing, anti-imaging, binary input and binary output chassis to power supply. |

| Attachment 1: electronics_rack_back.jpeg

|

|

| Attachment 2: electronics_rack_front.jpeg

|

|

| Attachment 3: mounted_chassis.jpeg

|

|

| Attachment 4: power_supply.jpeg

|

|

|

252

|

Wed Nov 1 18:24:01 2023 |

Shane | Update | CDS | CyMAC Power connections made |

Finished power connections today for the CyMAC chassis. Images attached. Had to switch the shrink fork terminals on the power supply cables to shrink ring terminals, but was able to get everything connected and secured. Upcoming work: turning on power supply and testing voltages/checking everything is turning on and lighting up correctly.

Configuration is as follows:

- Topmost Sorensen: +24V (reserved for FROSTI)

- Negative terminal: [negative terminal is grounded]

- jumper to Sorensen ground screw

- Sorensen 2nd from the top: +18V

- Positive terminal:

- white power cable wire for AA chassis

- white power cable wire for AI chassis

- white power cable wire for BI chassis

- white power cable wire for BO chassis

- Negative terminal: [negative terminal is grounded]

- jumper to Sorensen ground screw

- black power cable wire for AA chassis

- black power cable wire for AI chassis

- black power cable wire for BI chassis

- black power cable wire for BO chassis

Sorensen 3rd from the top: -18V

- Positive terminal:[positive terminal is grounded]

- jumper to Sorensen ground screw

- green power cable wire for BI chassis

- green power cable wire for BO chassis

- Negative terminal:

- green power cable wire for AA chassis

- green power cable wire for AI chassis

Bottommost Sorensen: +6V

- Positive terminal:

- white power cabe wire for timing chassis

- Negative terminal: [negative terminal is grounded]

- jumper to Sorensen ground screw

- green power cable wire for timing chassis

- black power cable wire for timing chassis

|

| Attachment 1: cymac_power_connected.jpeg

|

|

| Attachment 2: cymac_power_connections_back.jpeg

|

|

|

270

|

Fri Nov 17 14:06:01 2023 |

Shane | Update | Cleanroom | 5 zone particle count |

| Here's today's 5 zone particle count measurement for the cleanroom. Zone 5 (closest to back wall by fire cabinet) is still above the limit for the larger size ranges; everything else is in good shape and roughly 10 times under the limit. Not sure why zone 5 is still so dirty (maybe some of the electronics being stored in bags/bins on the upper shelf of the desk aren't clean?) but will focus cleaning efforts on this zone next time. |

| Attachment 1: 23.png

|

|

|

276

|

Wed Nov 22 15:46:50 2023 |

Shane | Update | CDS | DB25 signal connections for FROSTI heaters |

[Shane, Jon]

Installed new DC smart switch in electronics rack, configured power connections. Images attached. Attached is a diagram of the male DB25 signal connections to be used for FROSTI heaters. Also included below is table detailing pin and signal configuration.

| Pin |

Signal |

| 1 |

V+ Heater 1 |

| 2 |

V+ Heater 2 |

| 3 |

V+ Heater 3 |

| 4 |

V+ Heater 4 |

| 5 |

V+ Heater 5 |

| 6 |

V+ Heater 6 |

| 7 |

V+ Heater 7 |

| 8 |

V+ Heater 8 |

| 9 |

N/C |

| 10 |

N/C |

| 11 |

N/C |

| 12 |

N/C |

| 13 |

N/C |

| 14 |

RTN heater 1 |

| 15 |

RTN heater 2 |

| 16 |

RTN heater 3 |

| 17 |

RTN heater 4 |

| 18 |

RTN heater 5 |

| 19 |

RTN heater 6 |

| 20 |

RTN heater 7 |

| 21 |

RTN heater 8 |

| 22 |

N/C |

| 23 |

N/C |

| 24 |

N/C |

| 25 |

N/C |

|

| Attachment 1: DB25input_signals.pdf

|

|

| Attachment 2: IMG_3137.jpeg

|

|

| Attachment 3: dc_smart_switch_signal_connections.jpeg

|

|

|

285

|

Mon Dec 4 21:27:53 2023 |

Shane | Update | CDS | ADC-DAC loopback test results |

| Here are the test results from today's ADC-DAC loopback tests. Channels 14 and 15 were the only ones behaving abnormally. Not sure what the issue is, but needs further debugging. The DAC output was as expected for both of them, but the corresponding ADC inputs were the same regardless of what offset was used (hovering around values of -4 and -5). NOTE: all measurements listed in the attached table are 'averages' in the sense that the ADC inputs and DAC outputs hovered around the listed values, changing by +1 or -1. |

| Attachment 1: adc-dac_loopback_testing_results.pdf

|

|

|

287

|

Thu Dec 7 14:13:15 2023 |

Shane | Update | Cleanroom | cleanroom cleaning and particle count |

|

[Aiden, Shane, Michael, Luke, Cynthia]

cleaning cleanroom and particle count

- 12:30 pm: ran zero count test on particle counter

- 12:32 pm: started particle count.

- zone 3:

- 0.3 u: 59,488

- 0.5 u: 9561

- 1.0 u: 706

- zone 4:

- 0.3 u: 7732

- 0.5 u: 1912

- 1.0 u: 290

NOTE: Frame ceiling tile collapsed in cleanroom, explaining insanely high 0.3 u particle count in zone 3 (nearly 6 times above limit). Wiped down tile and put it back in ceiling frame.

- 12:56 pm: began surface check and wipedown, including softwalls

- 1:16 pm: started vacuuming the floor

- 1:32 pm: finished vacuuming the floor

- 1:33 pm: started mopping the floor

- 1:47 pm: finished mopping the floor

- 1:48 pm: started cleaning the buckets

- 1:53 pm: started mopping with IPA wipes

- 2:05 pm: finished mopping with IPA wipes

- 2:06 pm: changed sticky floor mats

- 1:53 pm: started particle count

- zone 3:

- 0.3 u: 6401

- 0.5 u: 3450

- 1.0 u: 1787

- zone 4:

- 0.3 u: 4073

- 0.5 u: 2452

- 1.0 u: 1039

|

|

302

|

Wed Jan 10 15:27:18 2024 |

Shane | Update | Cleanroom | cleanroom cleaning and particle count |

|

[Aiden, Shane]

cleaning cleanroom and particle count

- 2:03 pm: changed sticky floor mats

- 2:05 pm: started particle count

- zone 3:

- 0.3 u: 4863

- 0.5 u: 1205

- 1.0 u: 872

- zone 4:

- 0.3 u: 1953

- 0.5 u: 789

- 1.0 u: 457

- 2:35 pm: began surface check and wipedown, including softwalls and ceiling tiles

- 2:45 pm: started vacuuming the floor

- 2:56 pm: finished vacuuming the floor

- 2:57 pm: started mopping the floor

- 3:01 pm: finished mopping the floor

- 3:02 pm: started cleaning the buckets

- 3:05 pm: started mopping with IPA wipes

- 3:08 pm: finished mopping with IPA wipes

- 3:09 pm: started particle count

- zone 3:

- 0.3 u: 5528

- 0.5 u: 2203

- 1.0 u: 1662

- zone 4:

- 0.3 u: 1080

- 0.5 u: 415

- 1.0 u: 332

|

|

312

|

Wed Jan 31 14:37:26 2024 |

Shane | Summary | CDS | path directions for CyMAC model and parts library |

| Path to cds parts library in Matlab simulink: /usr/share/advligorts/src/src/epics/simLink. File name CDS_PARTS.mdl

Path to user models: /opt/rtcds/usercode/models, using file name c1msc.mdl |

|

329

|

Mon Feb 19 14:40:21 2024 |

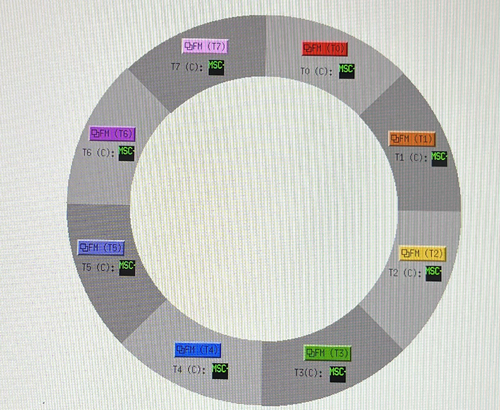

Shane | Update | CDS | MEDM screen for FROSTI temp readouts |

| Here's the latest draft of the MEDM screen for the FROSTI heating elements' temperature readouts. Note that the MEDM screen isn't actually this grainy, this just happens to be a photo of the lab monitor's screen off a phone. |

| Attachment 1: IMG_6094.jpeg

|

|

| Attachment 2: IMG_6092.jpeg

|

|

|

333

|

Wed Feb 21 11:58:30 2024 |

Shane | Update | Cleanroom | cleanroom cleaning and particle count |

|

[Luke, Shane, Tyler]

cleaning cleanroom and particle count

- 11:50 am: ran zero count test on particle counter

- 11:55 am: started particle count

- zone 3:

- 0.3 u: 1787

- 0.5 u: 581

- 1.0 u: 166

- zone 4:

- 0.3 u: 623

- 0.5 u: 290

- 1.0 u: 124

- 12:17 pm: began surface check and wipedown, including softwalls

- 12:25 pm: started vacuuming the floor

- 12:36 pm: finished vacuuming the floor

- 12:44 pm: started mopping the floor

- 12:57 pm: finished mopping the floor

- 12:58 pm: started cleaning the buckets

- 12:59 pm: started mopping with IPA wipes

- 1:05 pm: finished mopping with IPA wipes

- 1:06 pm: changed sticky floor mats

- 1:08 pm: started particle count

- zone 3:

- 0.3 u: 1621

- 0.5 u: 581

- 1.0 u: 332

- zone 4:

- 0.3 u: 1080

- 0.5 u: 457

- 1.0 u: 249

|

|

337

|

Fri Feb 23 15:01:48 2024 |

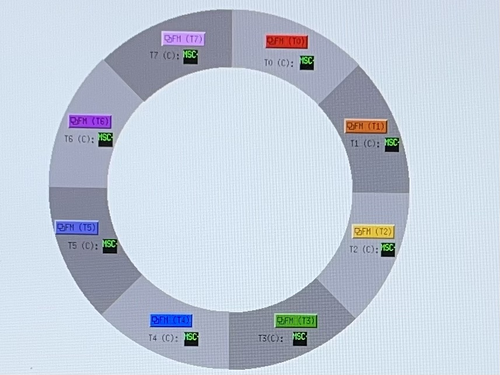

Shane | Update | CDS | Latest draft of MEDM screen for FROSTI readouts |

| Here's the latest draft of the MEDM screen for the FrOSTI temp and power readouts. Also, debugged the text readout boxes so they're now correctly reading out the live temperature and power values. |

| Attachment 1: IMG_6128.jpg

|

|

| Attachment 2: 23.jpg

|

|

|

346

|

Thu Feb 29 17:16:48 2024 |

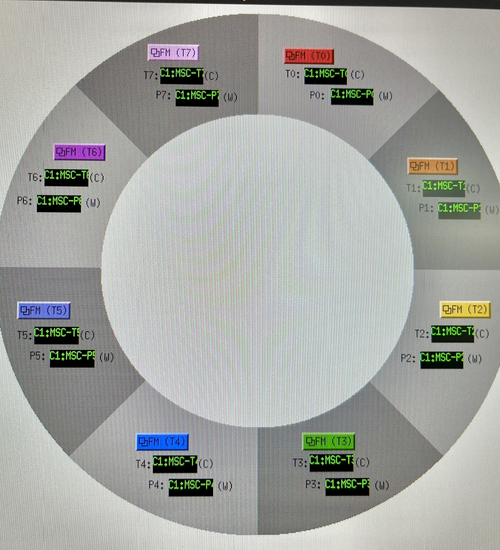

Shane | Update | CDS | MEDM screen for FROSTI T/P readouts |

| Here's the latest draft of the MEDM screen for the FROSTI temp and power readouts, now with a button linking to the c1msc file display. Size/color/label are all changeable, if adjustment is needed. Checked in execute mode as well, and it's working correctly. Also noticed that the MEDM file name has been changed to FROSTI.adl, which I'm noting here for future reference. Still in medm_sandbox directory. |

| Attachment 1: IMG_6259.jpeg

|

|

|

362

|

Wed Apr 17 15:07:04 2024 |

Shane | Update | Cleanroom | Cleanroom cleaning and particle count |

|

[Mohak, Luke, Luis, Shane, Cynthia, Michael, Xuesi]

cleaning cleanroom and particle count

NOTE: particle counter was found dead, with the charging dock unplugged. For future reference, if you need to unplug the dock, please either plug it back in when you're done, or make a note in an elog so someone else can come down and charge it.

- 1:07 pm: ran zero count test on particle counter

- 1:26 pm: started particle count

- zone 3:

- 0.3 u:1787

- 0.5 u:457

- 1.0 u:41

- zone 4: We were only able to charge the particle counter a small amount before starting the cleaning, so it died again halfway through this measurement, and we didn't get results for zone 4. In interest of time, we just put it on the charger and started the cleaning.

- 1:49 pm: began surface check and wipedown, including softwalls

- 2:16 pm: started vacuuming the floor

- 2:24 pm: finished vacuuming the floor

- 2:26 pm: started mopping the floor

- 2:32 pm: finished mopping the floor

- 2:32 pm: started cleaning the buckets

- 2:35 pm: started mopping with IPA wipes

- 2:43 pm: finished mopping with IPA wipes

- 2:43 pm: changed sticky floor mats

- 2:45 pm: started particle count

- zone 3:

- 0.3 u: 1288

- 0.5 u: 124

- 1.0 u: 0

- zone 4:

- 0.3 u: 415

- 0.5 u: 290

- 1.0 u: 0

|

|

369

|

Thu May 16 15:23:14 2024 |

Shane | Update | Cleanroom | Cleanroom cleaning and particle count |

|

[Luis, Michael, Luke, Shane]

cleaning cleanroom and particle count

- 1:45 pm: ran zero count test on particle counter

- 1:50 pm: started particle count

- zone 3:

- 0.3 u: 2660

- 0.5 u: 332

- 1.0 u: 41

- zone 4:

- 0.3 u: 8106

- 0.5 u: 2494

- 1.0 u: 831

- 2:08 pm: began surface check and wipedown, including softwalls

- 2:22 pm: started vacuuming the floor

- 2:39 pm: finished vacuuming the floor

- 2:43 pm: started mopping the floor

- 2:53 pm: finished mopping the floor

- 2:54 pm: started cleaning the buckets

- 2:59 pm: started mopping with IPA wipes

- 3:06 pm: finished mopping with IPA wipes

- 3:10 pm: changed sticky floor mats

- 3:06 pm: started particle count

- zone 3:

- 0.3 u: 1496

- 0.5 u: 83

- 1.0 u: 0

- zone 4:

- 0.3 u: 789

- 0.5 u: 83

- 1.0 u: 41

|

|

383

|

Tue Jun 25 12:34:18 2024 |

Shane | Update | Cleanroom | cleanroom cleaning and particle count |

|

[Luke, Shane, Xuejun, Mohak, Michael, Tyler, Cynthia]

cleaning cleanroom and particle count

- 10:45 am: ran zero count test on particle counter

- 11:02 am: started particle count

- zone 3:

- 0.3 u: 3284

- 0.5 u: 1247

- 1.0 u:332

- zone 4:

- 0.3 u: 1829

- 0.5 u: 581

- 1.0 u: 207

- 11:15 am: began hepavac of rest of lab

- 11:19 am: began surface check and wipedown, including softwalls

- 11:32 am: finished hepavac of rest of lab

- 11:35 am: started vacuuming the cleanroom floor

- 11:45 am: finished vacuuming the floor

- 11:47 am: started mopping the floor

- 11:55 am: finished mopping the floor

- 11:56 am: started cleaning the buckets

- 11:57 am: started mopping with IPA wipes

- 12:02 pm: finished mopping with IPA wipes

- 12:03 pm: changed sticky floor mats

- 12:04 pm: started particle count

- zone 3:

- 0.3 u: 3117

- 0.5 u: 374

- 1.0 u: 124

- zone 4:

- 0.3 u: 4531

- 0.5 u: 540

- 1.0 u: 0

|

|

388

|

Thu Jun 27 13:42:02 2024 |

Shane | Update | Cleanroom | cleanroom 5 zone particle count measurement |

| Here's today's 5 zone measurement of the cleanroom. We're above the limit by a bit in zone three (all three size ranges), likely as a result of the recent work installing FROSTI, so it could probably use another focused cleaning. Everything else is below the limit. |

| Attachment 1: 24.png

|

|

|

398

|

Mon Jul 8 17:01:45 2024 |

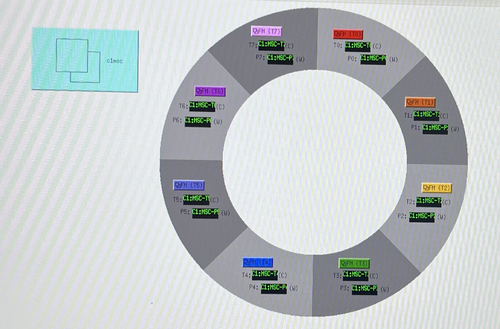

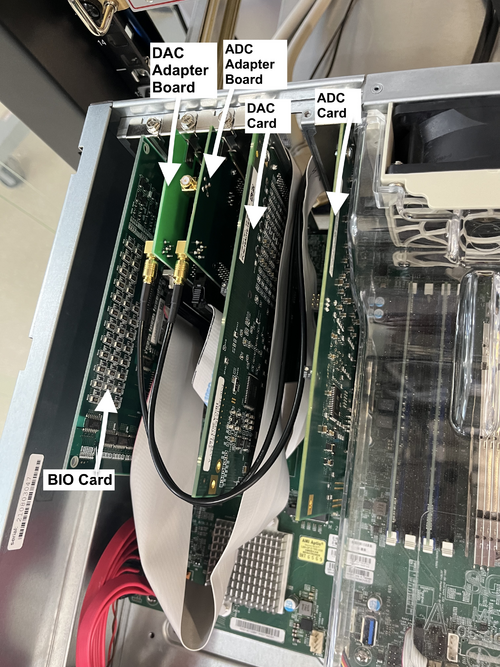

Shane | Update | CDS | New CyMAC internal layout |

| [Jon, Shane]

Internal layout of CyMAC has been updated (labeled image attached) to accommodate the replacement of the two ribbon cables. Looking down on the chassis from the front, and going from left to right, the new placement is as follows: BIO card, DAC adapter board, ADC adapter board, DAC card, ADC card. NOTE: As part of ADC-DAC loopback testing, we're disconnecting from the FROSTI readout chassis and using the cables to connect directly from ADC input channels to DAC output channels . Initial testing confirmed functionalility of all 32 ADC input channels and the first 8 DAC output channels. |

| Attachment 1: updated_cymac.jpeg

|

|

|

399

|

Tue Jul 9 18:19:50 2024 |

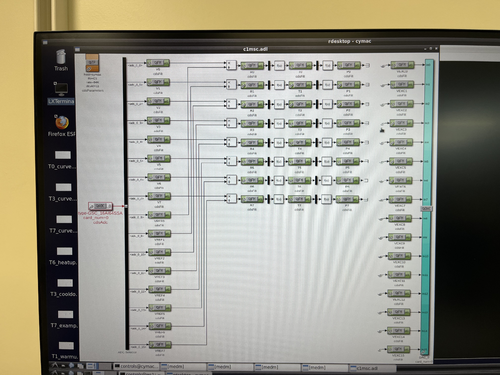

Shane | Update | CDS | ADC-DAC loopback testing and IOLAN installation |

| [Shane, Jon]

Finished ADC-DAC loopback testing today (see attached xlsx file or access directly here). All looks well with the first 8 channels, with the gain hovering just under 2. Also edited c1msc model in simulink to add channels 7-15 (the last 8 channels), and changed the rate back to 64K. See image 1 for the updated c1msc model. The last 8 channels are also looking good and show no problems, with slightly more scattering for the gain, but all values very close to 2.

We also installed the new eight-channel Perle IOLAN SDS8 terminal server today. Image attached.

NOTE: When we were installing it, we noticed an energized wire dangling from the 24V power supply. Has since been fixed and put back into place. |

| Attachment 1: iolanServerTerminal.jpeg

|

|

| Attachment 2: ADC-DAC_Loopback_Testing.xlsx

|

| Attachment 3: updatedc1msc.jpeg

|

|

|

410

|

Tue Jul 16 18:43:07 2024 |

Shane | Update | CDS | ADC-DAC loopback testing and IOLAN installation |

|

UPDATE:

Follow up ADC-DAC loopback testing now complete, matching all the ADC channels to a single DAC channel, and then matching all the DAC channels to a single ADC channel (see attached xlsx file or access directly here). Also note c1msc model file has been updated to include the second set of 16 ADC channels. The newly added channels also have their own filter modules, but those are not needed for anything other than the loop-back testing and can now be deleted if we don't want to keep them.

| Quote: |

| [Shane, Jon]

Finished ADC-DAC loopback testing today (see attached xlsx file or access directly here). All looks well with the first 8 channels, with the gain hovering just under 2. Also edited c1msc model in simulink to add channels 7-15 (the last 8 channels), and changed the rate back to 64K. See image 1 for the updated c1msc model. The last 8 channels are also looking good and show no problems, with slightly more scattering for the gain, but all values very close to 2.

We also installed the new eight-channel Perle IOLAN SDS8 terminal server today. Image attached.

NOTE: When we were installing it, we noticed an energized wire dangling from the 24V power supply. Has since been fixed and put back into place. |

|

| Attachment 1: Follow-up_ADC-DAC_Loopback_Testing.xlsx

|

|

419

|

Fri Aug 2 13:50:22 2024 |

Shane | Update | CDS | Serial Comm. Test (Agilent Turbo Pump) |

| Did a brief communication test with the agilent turbo pump today, to see if we could get serial communications up and running for it. Used a simplified python script with sockets package to establish a connection and send a simple command to query the pump's operational status. The connection was successful, and had no issues establishing. The command also sent successfully, and received a response. The response didn't make sense, though, as all the possible statuses correspond to integers 0-7, and this test returned the integer 15. Need to troubleshoot some more to figure out why it's returning nonsense values. Possible match-up issue with the way the information is being encoded on each end? At the very least, connection and command sending are both working fine, and this showed that the pin-out connections we were assuming (image attached) are correct for basic connection to work. |

| Attachment 1: pinouts.jpeg

|

|

|

Draft

|

Tue Oct 1 19:41:23 2024 |

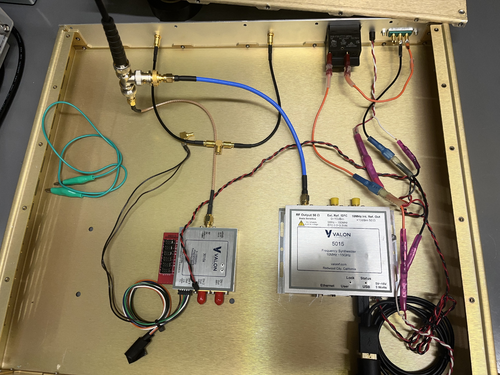

Shane | Update | CDS | CyMAC Timing Chassis Issue |

| [Shane, Luis]

Summary of the issue we've been having with the timing chassis: when we connect only the Valon 5015 to power, the timing signal comes out of it sinusoidal as expected and the status lights are steady and all looks good. As soon as we connect the 3010 to power, the signal (both coming out of the 5015 and coming out of the 3010) go flat and the status lights of the 5015 start to flicker.

We think what may be going on is that the 5015 is drawing just enough power to survive on its own, but when the current gets split to go to the 3010 as well, the 5015 takes more than it needs and becomes overpowered, and thus no longer outputs anything. We want to test further by powering them with two separate power supplies, but we need another one of the power connectors for the 3010 (the only one we have branches out from the connector to the 5015 and we don't want to cut any of the wires).

Images of the inside of the chassis, along with two roughly sketched circuit diagrams (one showing the current setup, in which they're powered by the same source, and one showing a possible test set up, in which they're powered separately. |

| Attachment 1: IMG_5917.jpeg

|

|

| Attachment 2: IMG_5803.jpeg

|

|

| Attachment 3: IMG_5804.jpeg

|

|

|

456

|

Thu Oct 3 19:35:04 2024 |

Shane | Update | Cleanroom | Cleanroom cleaning and particle count |

|

[Luke, Michael, Cynthia, Mary]

cleaning cleanroom and particle count

- 12:25 pm: started particle count

- zone 3:

- 0.3 u: 4614

- 0.5 u: 872

- 1.0 u:83

- zone 4:

- 0.3 u: 2411

- 0.5 u: 415

- 1.0 u: 83

- 12:48 pm: began surface check and wipedown, including softwalls

- 1:20 pm: started vacuuming the floor

- 1:30 pm: finished vacuuming the floor

- 1:34 pm: started mopping the floor

- 1:40 pm: finished mopping the floor

- 1:40 pm: started cleaning the buckets

- 1:42 pm: started mopping with IPA wipes

- 1:50 pm: finished mopping with IPA wipes

- 1:51 pm: changed sticky floor mats

- 3:44 pm: started particle count

- zone 3:

- 0.3 u: 3207

- 0.5 u: 624

- 1.0 u: 83

- zone 4:

- 0.3 u: 916

- 0.5 u: 83

- 1.0 u: 0

|

|

461

|

Thu Oct 17 13:24:23 2024 |

Shane | Update | CDS | Timing Chassis issue identified |

|

[Ma, Luis, Shane]

Working theory for the timing chassis issues had been that the 1A breaker was tripping and causing the failure of the Valon 5015 and 3010 to output the timing signal correctly. We just tried bypassing the breaker, running 6 V on the benchtop power supply (set the current limit to 1.5A), with the 5010 generating the sine wave to pass to the 3010. All worked correctly, and there were no issues. Square wave outputted by the 3010 was exactly as desired (image attached) at the correct frequency, and this confirms the issue was the breaker, not the valon 5015. Ready to go ahead with ordering a new replacement breaker.

|

| Attachment 1: IMG_6462.jpeg

|

|

| Attachment 2: IMG_6464.jpeg

|

|

|

465

|

Fri Oct 25 10:56:30 2024 |

Shane | Update | CDS | Timing Chassis fixed and reinstalled |

|

[Ma, Shane]

We replaced the 1A breaker in the timing chassis today with a 4A one, and tested that all is working well. The chassis successfully outputted the correct signal (image attached). The real time models have also been restarted and the CyMAC diagnostics screen is showing all green flags. Timing chassis has been closed up and reinstalled in the server rack.

|

| Attachment 1: successful_timing.jpeg

|

|

|

473

|

Thu Nov 14 11:58:05 2024 |

Shane | Update | CDS | Turbo pump connection troubleshooting |

| Attempted connection to the TV551 turbo pump through Varian/Agilent's software on spica. Successful connection established, and we are able to read out al the readings associated with the pump (status, temperature, etc) through the software, which is actually pretty extensive and well organized. Was able to stop and restart the pump with no issues. Serial communications seem to be working fine, and the current serial settings (baud rate 9600, serial type RS232) all match what the Iolan was expecting with the previous connection test. Also notable: the code used for the previous (failed) connection test is written using 'Letter protocol', which is the older of the two communications protocols supported by these kinds of pumps. This rules out the pump being too old to accept the newer communication format as the issue, since it's the older format being used anyway. Will continue trouble shooting to determine why previous connection test failed. |

|

484

|

Wed Dec 4 16:01:23 2024 |

Shane | Update | CDS | Vac serial interfacing troubleshooting update |

| Update on the issue with serial interfacing for the TV 551 turbo pump: Tried a new test today, to see if the commands being sent to the controller were actually getting through at all, since we know that no response is getting back to us. To test this, I sent the start/stop command for the pump, disconnected the serial connection and instead connected the controller to spica so I could run the manufacturer's software, and used the manufacturer's sotware to check the pump status manually. After trying a few variations of this test, during which the pump status did not change at all from 'normal' (meaning the stop command being sent was not actually received), we've concluded that the commands being sent to the pump with the serial comms code are not being received. Further troubleshooting needed. |

|

518

|

Wed Feb 19 13:44:48 2025 |

Shane | Update | CDS | Vac serial interfacing update |

|

[Jon, Shane]

Debugging update for vac system serial communications: we were able to successfully connect the smaller turbo pump to the Varian (manufacturer) software today by plugging the controller db9 directly into spica, and verified that the pump was able to send and receive information. Still no success on communication with the larger pump via python serial code, though. Issue potentially lies in the pinout mapping of the connectors, as the pinouts we'd been using work successfully for the small pump which only requires 3 connections (RXD, TXD, GND), but the large pump may require more. Tried to test this on the big pump by keeping the pinout setup for the small pump, and incrementally adding the remaining 6 connections on a one to one scale (Pin 1 matched to Pin 1, etc) between the controller DB9 and the field DB9 connected to the IOLAN ethernet cable. After each new connection was added, I retried running the serial connection code. None of the additional connections yielded any results, and the large pump remained unable to connect through the code. Next step is further looking into documentation on the pinouts to see if the large pump requires a different connection setup than the small pump.

|

|

527

|

Thu Feb 27 18:22:21 2025 |

Shane | Update | CDS | Ongoing work in server rack and desk area (1119) |

| As part of the vacuum communications debugging process, there is ongoing work in the server rack and desk area in 1119. Please be careful not to move any of the materials left out in the server rack or on the work bench. |

|

532

|

Tue Mar 4 10:47:03 2025 |

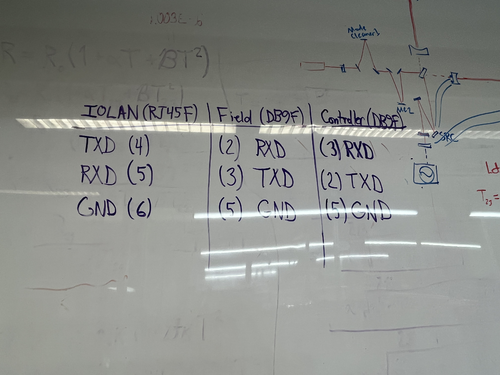

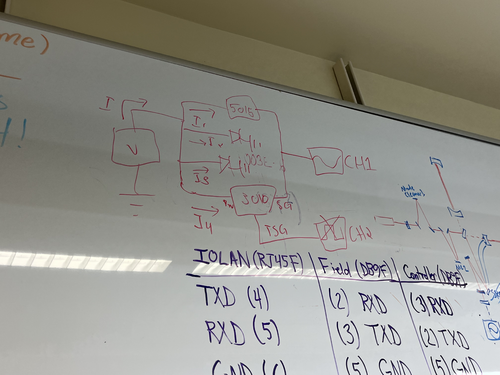

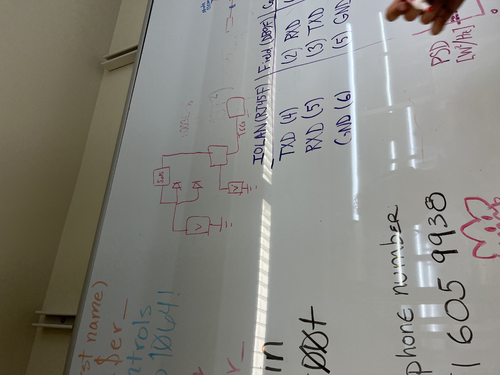

Shane | Update | CDS | Vac system pinouts |

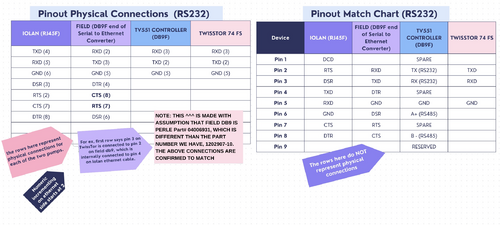

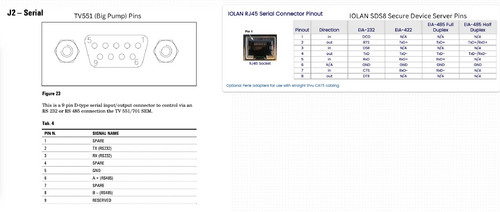

| Attached here are the pinouts, as we currently know them, for the vacuum system. The three items focused on here are the Agilent TwissTorr 74 FS turbo pump (the smaller/newer pump) and controller, the Agilent TV 551 Navigator turbo pump (the larger/older pump) and controller, and the Eight-channel Perle IOLAN SDS8 terminal server. The 'field' pinouts in the attached tables refer to the DB9 end of the RJ45F to DB9F converter. |

| Attachment 1: vac_pinouts_1.jpeg

|

|

| Attachment 2: vac_pinouts_2.jpeg

|

|

|

533

|

Wed Mar 5 12:16:28 2025 |

Shane | Update | CDS | Vac system communications update |

|

[Shane, Jon]

Update on the serial interfacing with the vacuum system: both turbo pumps are now able to successfully communicate through the code. The older pump, for unknown reasons, required a newer version of the communication syntax (despite the newer, small pump being able to communicate fine with the old communication format). We have also confirmed that the newer pump works with this new format as well. Next step is interfacing the pressure gauge.

|

|

534

|

Wed Mar 5 18:13:20 2025 |

Shane | Update | CDS | vac system comms |

|

[Shane, Jon]

Update on the serial interfacing with the Inficon VGC503 pressure gauge: We began setup of the Inficon pressure gauge today. We configured the ethernet setting via USB and assigned it a static IP address of 192.168.1.30, which is listed in the network table on the lab wiki. It is showing up on the network successfully, and is responding to pings. Will attempt communication via code next.

|

|

535

|

Mon Mar 10 17:03:52 2025 |

Shane | Update | CDS | Pressure Gauge successful connect |

| Vac system serial interfacing update: the pressure gauge is now able to communicate successfully through the code. It's been set to a static ip of 192.168.1.30, on port 8000. |

|

565

|

Wed Apr 30 13:42:45 2025 |

Shane | Update | CDS | UPS comms successful |

| Update on UPS1 serial interfacing: communication is now successful. On 4/15/25 we connected to UPS1 via ethernet rather than USB, and manually added its static ip address (noted in lab network wiki) to the router. Able to connect and unpack all desired data nicely using telnet server connection via telnetlib. In process of finalizing code and will work next on interfacing UPS2. |

|

1

|

Sun Apr 10 15:39:49 2022 |

Rutuja Gurav | HowTo | Computer Scripts/Programs | HowTo: Renew the Let's Encrypt SSL certificate using certbot |

Port 80 is kept closed by default. This might be causing the certbot auto-renewal cronjob to fail. Therefore we must renew the certificate manually.

Step 1: Open port 80. (This is needed as the certificate renewal process runs some tests which requires client communication over port 80)

Step 2: Run the following command

sudo certbot certonly --force-renew -d richardsonlab.ucr.edu

Step 3: Confirm the certificate was renewed by running the following command

sudo certbot certificates

|