| ID |

Date |

Author |

Type |

Category |

Subject |

|

207

|

Tue Aug 15 13:32:37 2023 |

Sophia | Update | Scripts/Programs | Update on Laser Noise Data Collection and Analysis: Dynamic CSD and PSD Plots |

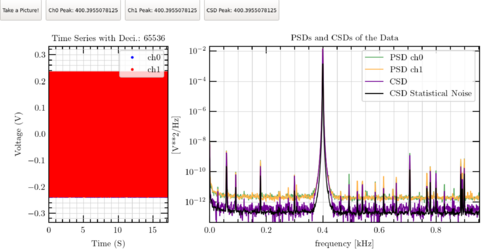

| I have now fixed all issues that I was having this morning, and have added text boxes which show the peak values of both PSD's and the CSD alongside the graphs. They also update continuously with the graph. This is shown in the top image. The laser was driven at 400Hz, and had 0.5V peak to peak voltage, both of which appear correctly in the below graphs.

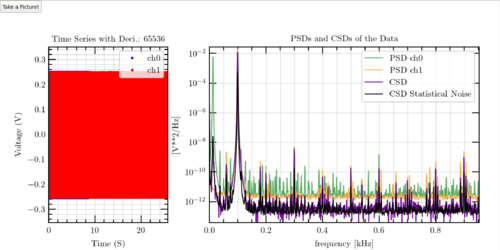

Now that the code is almost fully working (we will finish debugging the screenshot method later today), our plan tomorrow is to drive the laser and see how the code performs with it. The below graph is from us driving the function generator at 100Hz to test the range.

Update:

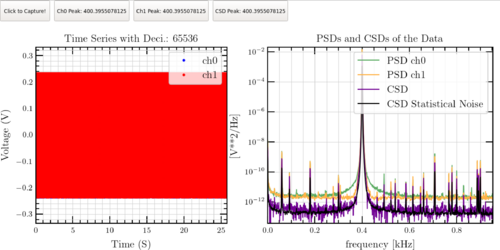

Bottom graph is new version of graphs with better distribution of both graphs. |

| Attachment 1: Screenshot_2023-08-15_at_4.27.58_PM.png

|

|

| Attachment 2: Screenshot_2023-08-15_at_2.21.18_PM.png

|

|

| Attachment 3: Screenshot_2023-08-15_at_5.25.05_PM.png

|

|

|

208

|

Tue Aug 15 16:04:23 2023 |

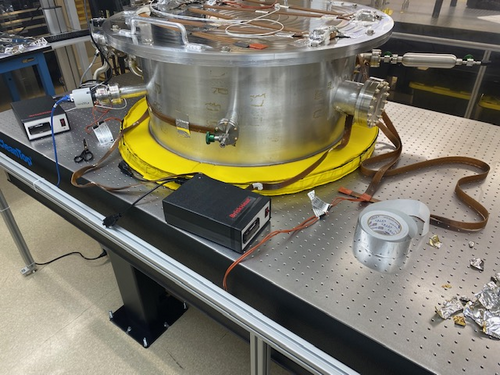

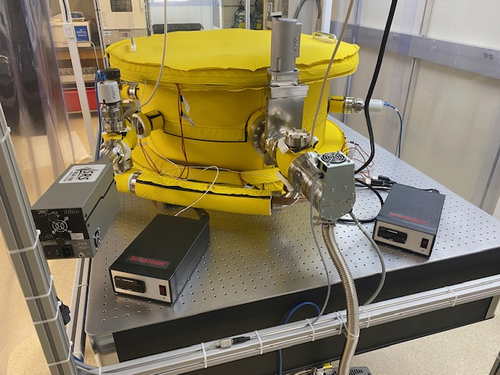

Aiden | Update | VAC | VAC Heating System Update |

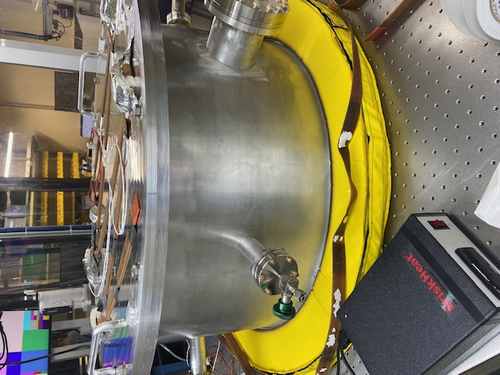

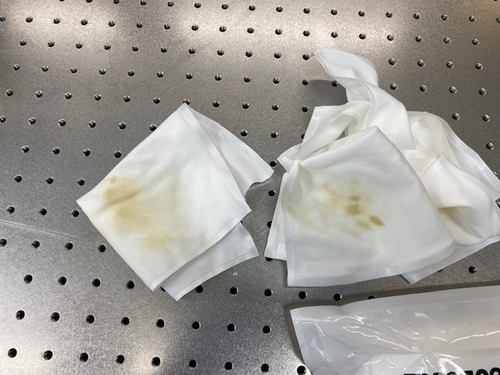

Pulled off the rest of the heater tape along with the aluminum tape left behind. The aluminum tape adhesive left behind a ton of junk on the walls of the chamber. This is probably due to excessive heating. In order to get the adhesive off I sprayed a vector alpha wipe with acetone and wiped down the walls. This took a lot of acetone to get it off.

When removing some of the aluminum tape I noticed small sections that seemed to have been melted to the silicone part of the heater tape and would have been damaging to try and forcefully remove it.

The heater tape is now ready to be put on again but now with the start of the tape placed on the other side so that the PID controllers can be placed on the shelf above the chamber and be seen outside of the curtain.

|

| Attachment 1: IMG_4609.jpg

|

|

| Attachment 2: IMG_4610.jpg

|

|

| Attachment 3: IMG_4611.jpg

|

|

| Attachment 4: IMG_4612.jpg

|

|

| Attachment 5: IMG_4613.jpg

|

|

| Attachment 6: IMG_4614.jpg

|

|

|

209

|

Tue Aug 15 16:10:06 2023 |

Celeste | Update | TCS | 8/15/2023 Simulation Progress |

|

| Attachment 1: Simulation_Progress__1_32nd_Model_(2).pdf

|

.png)

|

|

210

|

Wed Aug 16 16:55:40 2023 |

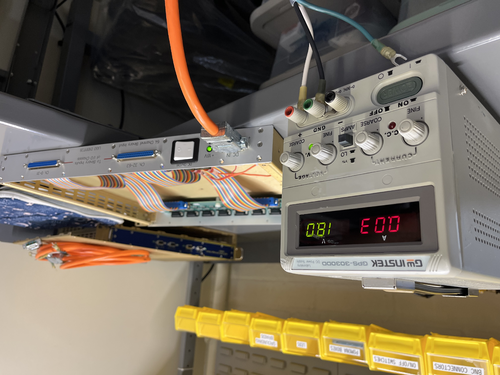

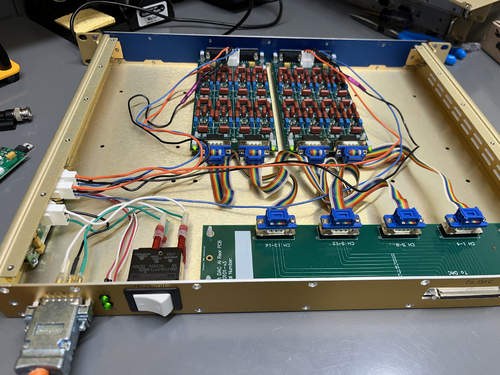

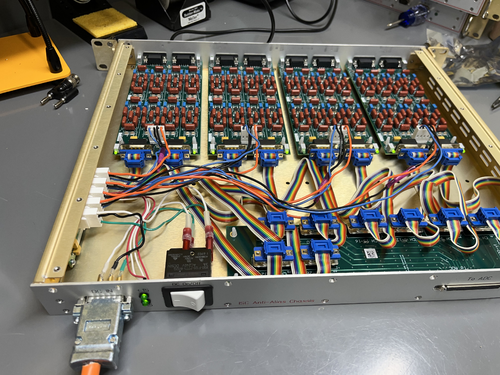

Shane, Jon | Update | CDS | external power supply cables finished |

| All four external power supply cables for the CyMAC chassis are now assembled. Using them now to test if chassis power up correctly. |

| Attachment 1: IMG_9251.jpeg

|

|

|

211

|

Wed Aug 16 17:17:02 2023 |

Shane, Jon | Update | CDS | Binary input chassis powering correctly |

| Binary input chassis passed power-on test, and is lighting up as expected. Binary output chassis also successfully powered on. AA and AI chassis not powering on correctly, need to do some debugging to find the problem. |

| Attachment 1: IMG_9253.jpeg

|

|

|

212

|

Thu Aug 17 15:02:44 2023 |

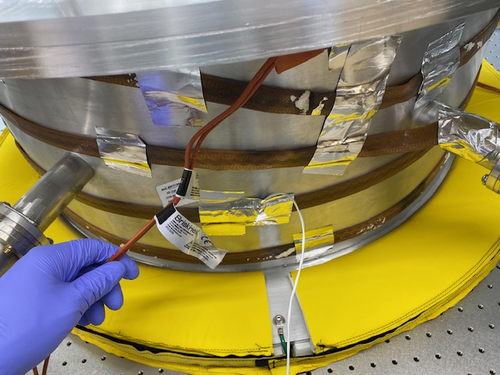

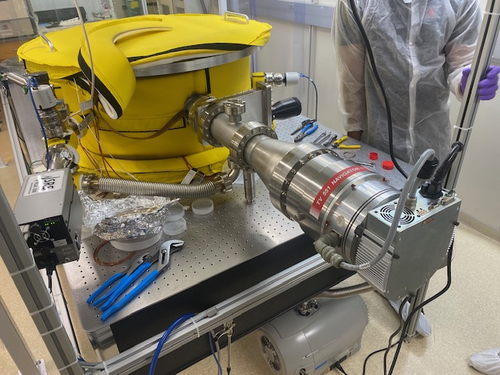

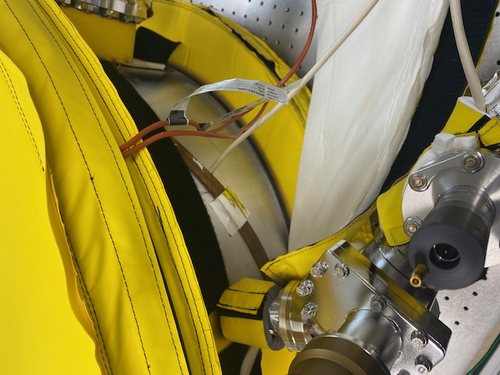

Aiden | Update | VAC | VAC Heating System Update |

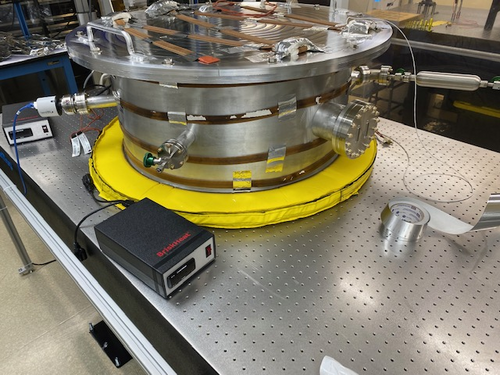

Put the heating tape back on and made sure to have 4 coils around the barrel of the chamber. To make this happen I did not put any heater tape on the ports but made sure to place some of the heater no more than 1 inch away from the ports. Also re-placed some of the heating sensors. For the PID controllers there is one sensor placed on the lid and one sensor placed on the barrel. For the temperature alarms one sensor was placed near the flange of the turbo pump and another placed on the cross in the RGA line. Note that all four of these sensors were placed under the heating tape compared to the last few bakes where they were on top.

The insulation was also put back on and now the chamber should be ready for a low temperature bake after some RGA data is taken before for comparison.

|

| Attachment 1: IMG_4615.jpg

|

|

| Attachment 2: IMG_4616.jpg

|

|

| Attachment 3: IMG_4617.jpg

|

|

| Attachment 4: IMG_4618.jpg

|

|

| Attachment 5: IMG_4619.jpg

|

|

| Attachment 6: IMG_4621.jpg

|

|

| Attachment 7: IMG_4622.jpg

|

|

| Attachment 8: IMG_4623.jpg

|

|

| Attachment 9: IMG_4624.jpg

|

|

| Attachment 10: IMG_4625.jpg

|

|

| Attachment 11: IMG_4627.jpg

|

|

|

213

|

Thu Aug 17 15:18:48 2023 |

Aiden | Update | VAC | VAC Heating System Update |

| Relocated the PID controllers so that the heating tape could be plugged in. In the picture the left one controls the top half of the chamber along with the RGA line and has its sensor on the lid near a fold. The right one controls the bottom half along with the turbo pump line and the bypass line and has its sensor on the barrel of the chamber. The chamber is almost ready to bake again and just needs to have the full range gauges and RGA electronics box removed. |

| Attachment 1: IMG_4628.jpg

|

|

|

214

|

Mon Aug 21 17:13:25 2023 |

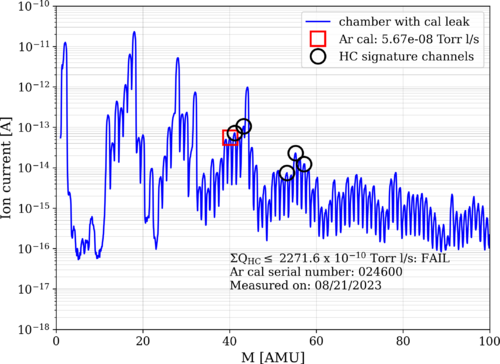

Aiden | Update | VAC | Vacuum Chamber Baking Update |

Came in to take RGA data and found the turbo pump drawing .38 Amps. This was much higher than what it was on Friday. I investigated and found that the breaker had flipped controlling the power strip that the scroll pump was on. The scroll pump was thus not running. I flipped the breaker back and turned the scroll pump back on. I do not know if this will be a reoccurring problem as this has happened before, or if this was due to the storm. Either way the scroll pump is running and the turbo pump is now only drawing .18 Amps at 31 C.

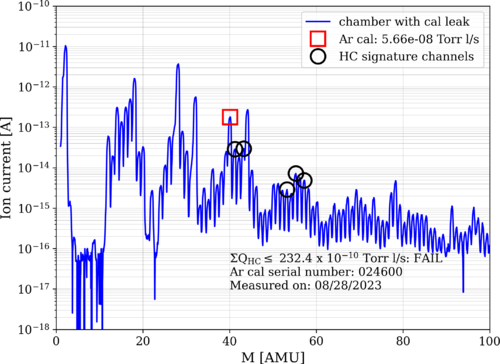

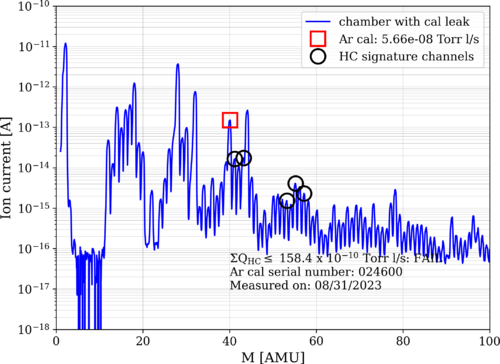

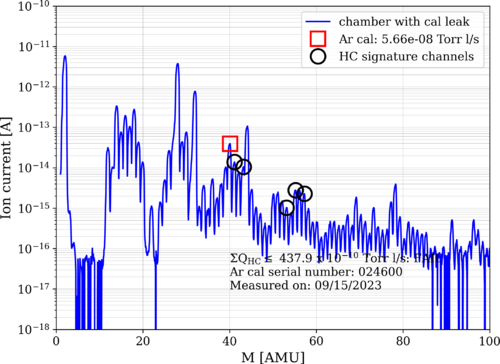

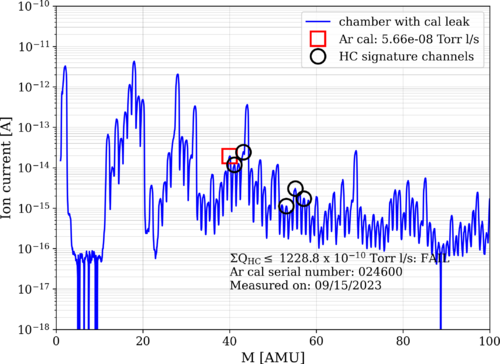

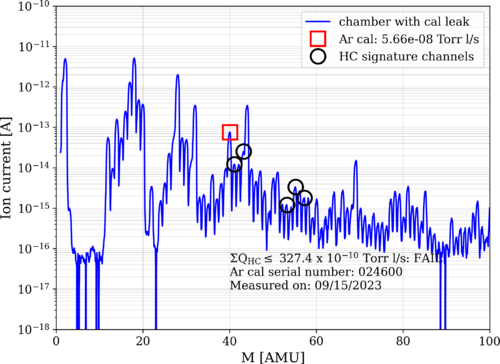

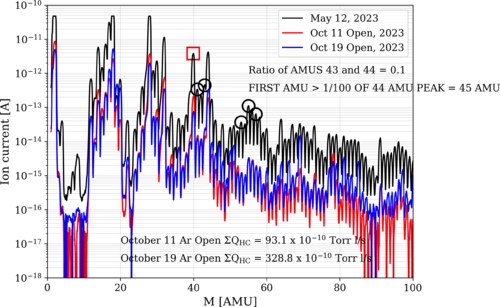

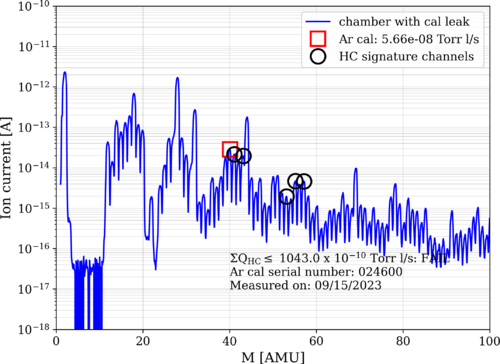

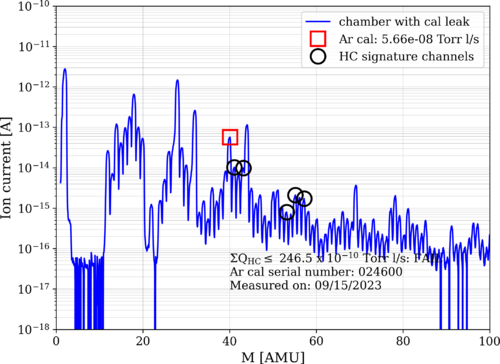

Below are the graphs for the RGA scan that I took before starting bake 4. I have not overlaid them yet so the first one is for Argon leak closed and the second is the Argon leak open. It seems that the chamber had gotten dirtier since the leak and there is still a lot of water left in the chamber. I assume the water will go away after the low temp bake but the HC count may not go down without a longer baker. I also measured the pressure before starting the bake and it was 4.16 e-7 and 3.31 e-7 torr for t he main body volume and RGA volume respectively.

When starting the bake I noticed that the temperature sensor placed on the cross in the RGA volume was reading 40 C hotter that what the PID controller was reading for the lid. I had to remove some of the heater tape from the cross as it was way too hot compared to the lid. After removing the second strip across the cross it is still much hotter than most parts due to it being such a small part compared to the large lid. I hope that after a little bit of equilibration time that the difference between these numbers will go down. Both PID controllers were set to 120 C. The RGA cross was reading 130 C and the Turbo pump cross was reading 76 C.

|

| Attachment 1: bake3_230821_ArC.png

|

|

| Attachment 2: bake3_230821_ArO.png

|

|

|

215

|

Mon Aug 28 14:43:50 2023 |

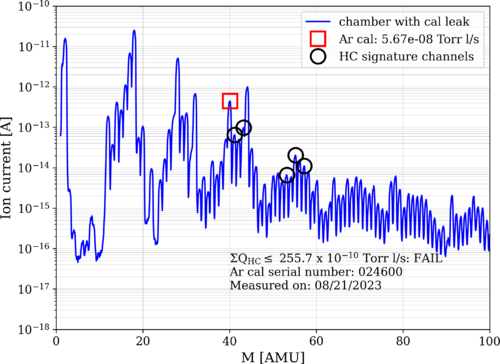

Aiden | Update | VAC | Vacuum Chamber Baking Update |

| The PID controllers were turned off on Friday and the chamber was left to cool over the weekend. Just took data and it looks like signal to noise ratio is pretty bad again. I do not know if this means we need a hotter bake or if the chamber needs some more time to cool down. I will overlay this data and make sure to take a second set a bit later to compare. Some good news though is that the chamber has reached a pressure below 10e-8 torr with the full range gauge above the RGA line reading 6.85 e-8 torr and still dropping. |

| Attachment 1: bake4_230828_ArC.png

|

|

| Attachment 2: bake4_230828_ArO.png

|

|

|

216

|

Tue Aug 29 19:09:21 2023 |

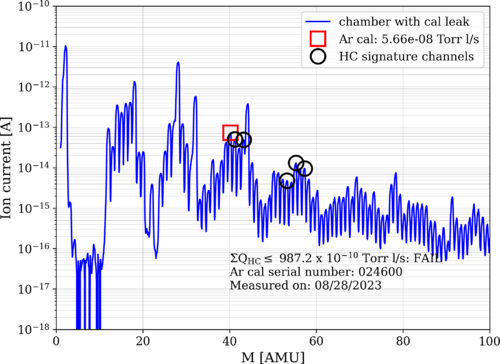

Aiden | Update | VAC | Vacuum Chamber Baking Update |

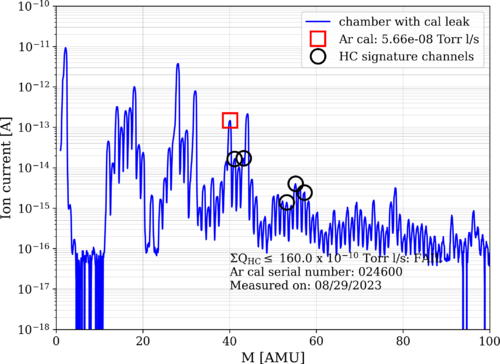

| Here are some more plots with the RGA data take August 29. It seems that more pumping time has led to the HC levels being dramatically reduced compared to only a day ago. The pressure also rises significantly when turning on the RGA filament and it doe not go back down to the pressure before turning it on while the RGA is still running. The pressure after I left was 6.86 e-8 torr. |

| Attachment 1: bake4_230829_ArO.png

|

|

| Attachment 2: bake4_230829_ArC.png

|

|

|

217

|

Tue Aug 29 22:07:38 2023 |

Aiden | Update | General | Electronic Bench |

| Dr Richardson is working on mounting more power supplies in the server rack and is using the electronics bench. Be aware to not move anything on the bench itself. |

| Attachment 1: IMG_4632.jpg

|

|

|

218

|

Thu Aug 31 12:56:29 2023 |

Aiden | Update | VAC | Vacuum Chamber Baking Update |

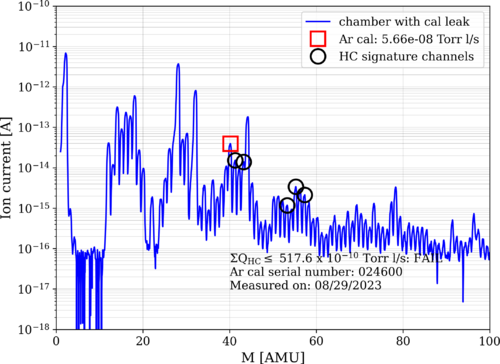

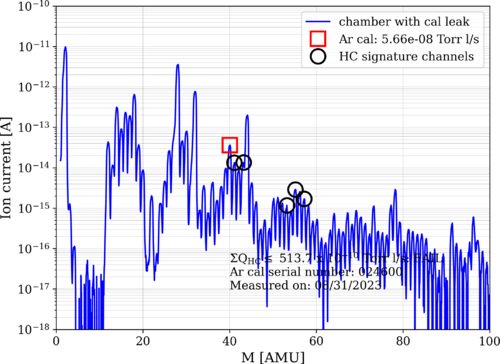

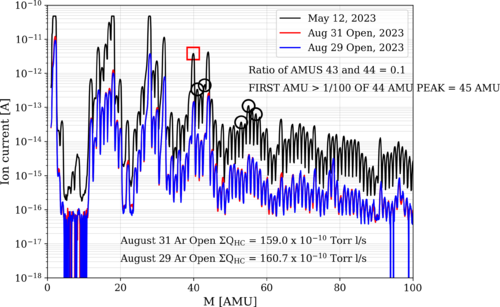

| Took some more RGA data to see if the HC levels have further declined since bake 4 and it seems that it has started to plateau with August 29 160.7 e-10 Torrl/s and August 31 giving 158.4 e-10 Torrl/s. The pressure of the chamber before taking data was 5.1 e-8 Torr. I have attached an overlay of the data from August 29 and August 31. It seems that the extra two days has not noticeably changed the data and another bake will most likely be needed to meet LIGO's HC specifications. The pressure after leaving the RGA off for a bit was 5.9 e-8 torr and it was still slowly decreasing. |

| Attachment 1: bake4_230831_ArC.png

|

|

| Attachment 2: bake4_230831_ArO.png

|

|

| Attachment 3: bake4_230829_ArO.png

|

|

|

219

|

Fri Sep 1 19:21:19 2023 |

Aiden | Update | VAC | VAC System Heating Update |

| Started bake 5 today. This will hopefully be a longer and hotter bake with it lasting 6-7 days at around 150 C. The pressure in the chamber before removing the full range gauge and RGA box was 5.01 e-8 torr. The Argon leak was also left open for this bake to hopefully get rid of particulates on it. I also put the heater tape I removed last time back onto the RGA cross. This made the heating up process take much longer as I had to not increase too much or the cross would heat above 150 C. Hopefully some PID settings in the future will help with this issue. I was able to set the PID controllers to 140 C and after some equilibrium time I should be able to get the temperature up to 150 C. The temperature sensors are reading 150 C and 77 C for the RGA cross and Turbo pump cross respectively. The Turbo pump is drawing the normal .17 Amps at 33 C. |

|

220

|

Tue Sep 5 16:43:19 2023 |

Aiden | Update | General | VAC System Heating Update |

| Checked on bake 5 today after 3 days of equilibrium. The RGA cross is at 106 C and the turbo pump cross is at 74 C. This was reached while the PID controllers were at 140 C. I will now slowly raise the temperature to 150 on the PID controllers and see if the difference in the RGA cross can be reduced. |

|

221

|

Thu Sep 7 19:24:25 2023 |

Peter | Update | VLC Update | VLC Launch Chain |

| The launch optics up to the Faraday Isolator have been added to the breadboard. In the first image, the optics are (from L to R) the stirring mirror, half-wave plate, polarizing cube, 100mm f lens, electro-optical modulator, Faraday isolator, 50mm lens (not part of final design), stirring mirror (not part of final design) |

| Attachment 1: IMG-3404(1).jpg

|

.jpg.png)

|

| Attachment 2: IMG-3408(1).jpg

|

.jpg.png)

|

|

222

|

Fri Sep 8 16:10:43 2023 |

Aiden | Update | VAC | VAC System Heating Update |

| Turned off the PID controllers to let the chamber cool down. Final temperatures for the RGA cross and Turbo pump cross were 113 C and 80 C respectively. The system should be cool enough to start taking measurements on Monday. |

|

223

|

Mon Sep 11 16:02:42 2023 |

Aiden | Update | VAC | VAC System Heating Update |

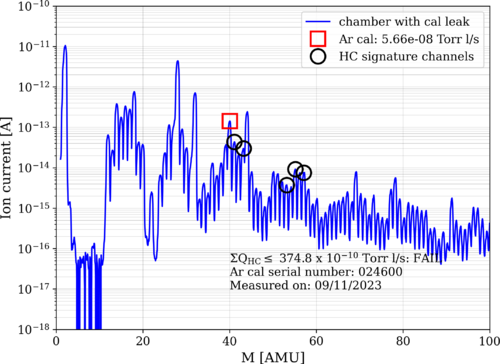

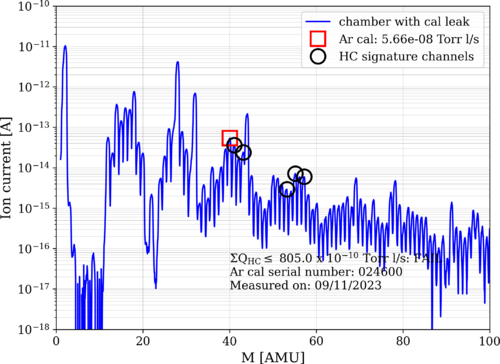

| The chamber has cooled down from bake 5 and I took the first set of data. The pressure measured during the RGA measurements reached 9.98 e-8 torr. The data shows that the chamber got dirtier, however this has been the case for every first scan after a bake so I assume there are still some more hydrocarbons to be vacuumed out and that the second scan will most likely give a better idea of where the chamber is at. After turning off the RGA the pressure immediately dropped to 7.4 e-8 torr and was still dropping. |

| Attachment 1: bake5_230911_ArO.png

|

|

| Attachment 2: bake5_230911_ArC.png

|

|

|

224

|

Tue Sep 12 15:31:31 2023 |

Aiden | Update | Clean & Bake | Clean and Bake Batch 15 |

| Cleaned and Baked the SS screws for the heater mount. Check the Clean and Bake data base on the website to get a precise list of the parts and their numbers. Cleaned them with liquinox in the ultra sonic washer for 10 minutes. Then dried them with nitrogen. Then put the stainless steel parts into the oven for the following steps; 1. Ramp to 100 C in 15 minutes 2. Dwell at 100 C for 30 minutes 3. Ramp to 200 C in 30 minutes 4. Dwell at 200 C for 48 hours 5. Turn off |

| Attachment 1: IMG_4647.jpg

|

|

|

225

|

Thu Sep 14 17:05:38 2023 |

Shane, Jon | Update | CDS | Timing chassis setup and testing |

| Tested the setup today for the timing chassis (intended to provide the timing reference for the CyMAC). Was able to read the correct frequency, but voltage was significantly lower than needed. Still identifying source of problem, and looking into the relationship between the supportable ohm load and the voltage. |

|

226

|

Fri Sep 15 17:33:35 2023 |

Aiden | Update | VAC | Vacuum Chamber Baking Update |

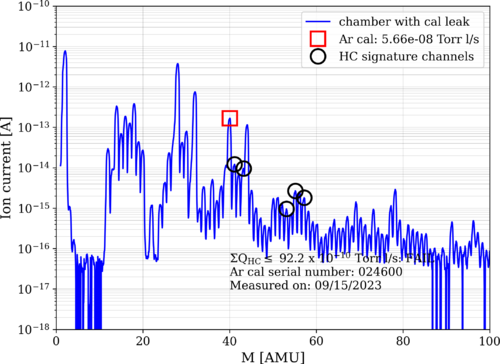

| Took some more RGA data and see that the chamber has gotten much cleaner since monday. Next step would be another bake with some focus around heating the RGA filament more. The pressure in the chamber before testing was 5.32 e-8 torr. |

| Attachment 1: bake5_230915_ArC.png

|

|

| Attachment 2: bake5_230915_ArO.png

|

|

|

227

|

Thu Sep 28 15:17:13 2023 |

Aiden | Update | Clean & Bake | Clean and Bake Batch 16 |

| Bagged and Tagged the parts from batch 15 and started baking batch 16 which includes the 6" to 8" reducer. |

|

228

|

Fri Sep 29 11:22:33 2023 |

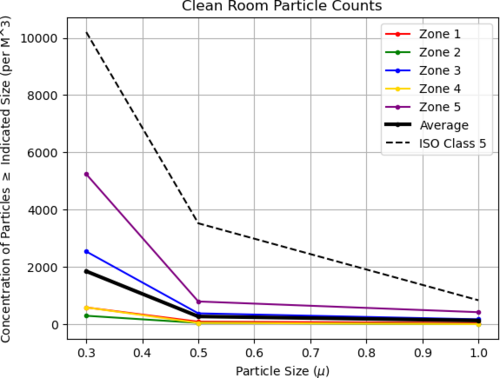

Shane, Aiden | Update | Cleanroom | cleaning and particle count |

|

[Aiden, Shane]

cleaning cleanroom and particle count

- 10:06 am: ran zero count test on particle counter

- 10:07 am: started particle count

- zone 3:

- 0.3 u: 2203

- 0.5 u: 831

- 1.0 u: 540

- zone 4:

- 0.3 u: 374

- 0.5 u: 124

- 1.0 u: 124

- 10:25 am: began surface check and wipedown

- 10:34 am: started vacuuming the floor

- 10:44 am: finished vacuuming the floor

- 10:45 am: started mopping the floor

- 10:49 am: finished mopping the floor

- 10:50 am: started cleaning the buckets

- 10:57 am: started mopping with IPA wipes

- 11:01 am: finished mopping with IPA wipes

- 11:02 am: changed sticky floor mats

- 11:03 am: started particle count

- zone 3:

- 0.3 u: 2535

- 0.5 u: 374

- 1.0 u: 166

- zone 4:

- 0.3 u: 581

- 0.5 u: 41

- 1.0 u: 0

|

|

230

|

Fri Sep 29 11:53:54 2023 |

Shane | Update | Cleanroom | 5 zone particle count measurement in cleanroom |

| Today's 5 zone measurement of cleanroom particulate concentration is attached |

| Attachment 1: 23.png

|

|

| Attachment 2: 23.png

|

|

|

231

|

Fri Sep 29 17:27:30 2023 |

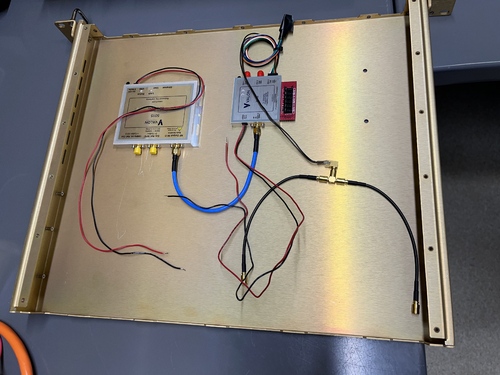

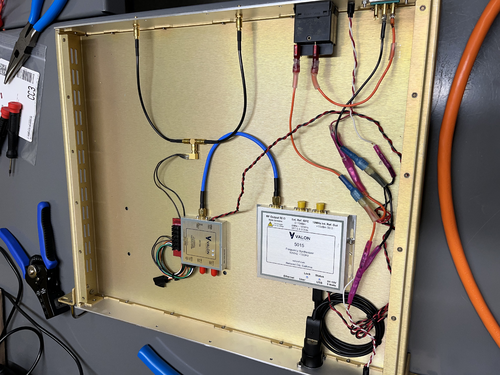

Shane, Jon | Update | CDS | Timing chassis assembly progress (CyMAC) |

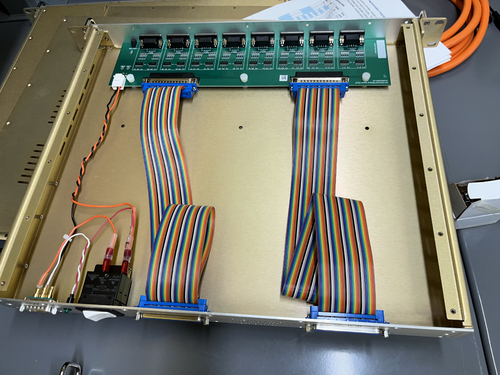

| Worked on timing chassis assembly today for the CyMAC, settled on layout (see attachment 1). Frequency synthesizer and frequency divider tentatively mounted. Next steps involve putting together and installing an LED and DC on/off switch assembly like the one in the binary input chassis (attachment 2 for comparison; orange and black wires in BI chassis analogous to red and black wires in timing chassis). Will also use front and back panels of BI chassis as a template for the timing chassis panels, with the following alterations: two SMB feedthroughs in place of the ribbon cable connections shown on the back panel, the addition of an LED on the front panel to indicate power, and potentially a spot on the front panel for usb connection to programmable frequency synthesizer. |

| Attachment 1: timing_chassis.jpeg

|

|

| Attachment 2: BI_chassis.jpeg

|

|

|

232

|

Tue Oct 3 15:07:48 2023 |

Aiden | Update | Clean & Bake | Clean and Bake Batch 17 |

| Cleaned and baked all the stainless steel parts in Batch 17. Check data base for more details on this. |

|

233

|

Sat Oct 7 17:10:27 2023 |

Aiden | Update | Clean & Bake | Clean and Bake Batch 18 |

| Bagged and tagged the parts from Batch 17 and placed them in the clean room on the optic table. Also started an aluminum batch of parts that included the kf clamps and the heater mounting parts. |

|

234

|

Mon Oct 9 11:06:17 2023 |

Peter | Update | VLC Update | VLC Launch Chain |

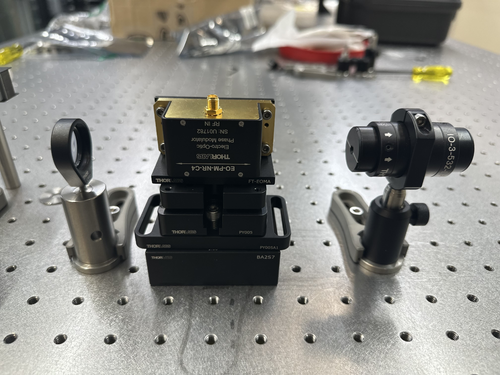

| Implemented the new stage for the EOM. Took power data at different positions in the launch chain. Beam waist: 0.066mm (beam waist is inside EOM). Power before EOM: 0.473mW. Power after EOM: 0.452mW. Power after Faraday Isolator: 0.415mW. Might need to adjust better to configure for clipping losses. Images of setup are attached below. |

| Attachment 1: IMG-3540.jpg

|

|

| Attachment 2: IMG-3538.jpg

|

|

| Attachment 3: IMG-3533.jpg

|

|

| Attachment 4: IMG-3522.jpg

|

|

|

235

|

Mon Oct 9 11:29:37 2023 |

Tyler | Update | Electronics | PSD/CSD Plot Updates |

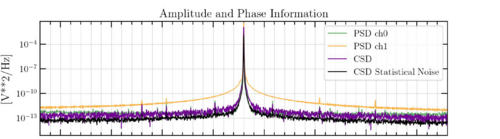

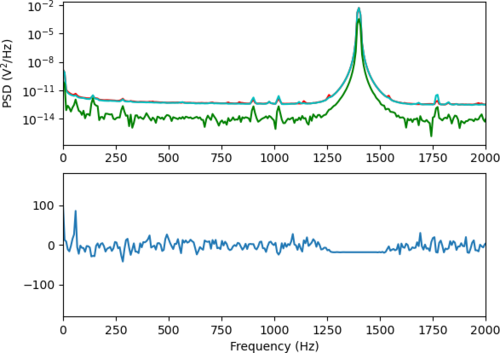

| Continuing from Sophia's SURF Project this summer: Plotting the Power-Spectral Densities (PSDs) and Cross-Spectral Densities of two signals.

A continued issue that has been observed in the plots is the random "jump" of one PSD curves. Below, a 1.4 kHz signal is driven with a magnitude of 0.7 Vpp, and connected to the two output ports of the Red Pitaya via an SMC T-Adapter. At the moment, I anticipate that this bug might have something to do with the Real-Time GUI code being used, since this hasn't been observed when running the calculations without it (see below). |

| Attachment 1: Screenshot_2023-10-09_at_11.20.25_AM.png

|

|

| Attachment 2: welch_csd-2.png

|

|

|

236

|

Mon Oct 9 16:59:21 2023 |

Shane, Jon | Update | CDS | timing chassis power cable and AI chassis testing for CyMAC |

[Shane, Jon]

Today's CyMAC work:

- Finished assembling external power supply cable for the timing chassis (see attached image)

- Also did some debugging of AA and AI chassis re: power issues. After testing voltages at various test points on the power regulator board (TP1-TP6) in the AA chassis, it seems like it's the source of the problem. Used bench DC power supply to test, running 15V, and the correct voltage is coming in to the board but something significantly smaller is being output. We're also getting unexpected negative signs on voltage at certain test points, with leads in correct positions

- Upon further examination, it looks like the lights on the filter boards are actually turning on (in both the AA and AI chassis), though it's only 2/4 lights on each board and they are very faint

- Corrected DC on/off switch spade lug orientation in AI chassis.

- Tested AI chassis power regulator board to see if the problem was the same, and found again that voltage coming in was correct, and voltage going out was not.

- In case of interest in exact numbers, results were as follows:

- Voltage difference between TP1(+Vin) and TP6(-Vin) is ~30V

- Voltage difference between grounded chassis wall and TP1 (+Vin) is ~15V

- Voltage difference between grounded chassis wall and TP6(-Vin) is ~-15 V

- voltage difference between TP2(+Vout) and TP5(-Vout) is ~3V

- Voltage difference between TP3 (gnd) and TP2(+Vout) is -0.065V

- Voltage difference between TP5(-Vout) and ground is ~3V

|

| Attachment 1: IMG_1457.jpeg

|

|

|

237

|

Mon Oct 9 21:41:24 2023 |

Aiden | Update | Clean & Bake | Clean and Bake Batch 19 |

| Bagged and tagged the parts from batch 18. Started the Copper batch that includes all the gaskets needed to start the vacuum chamber upgrade. |

|

238

|

Wed Oct 11 20:47:11 2023 |

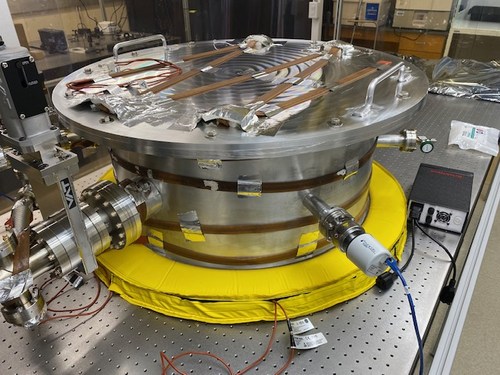

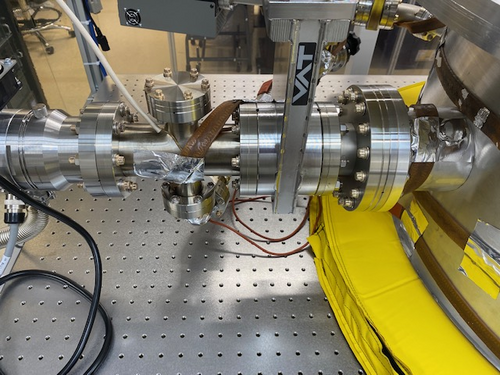

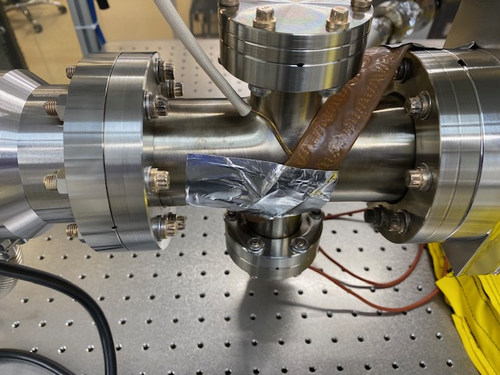

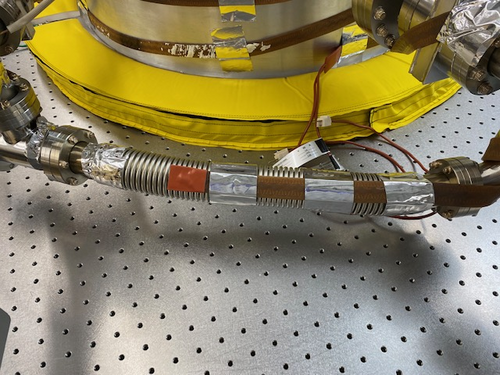

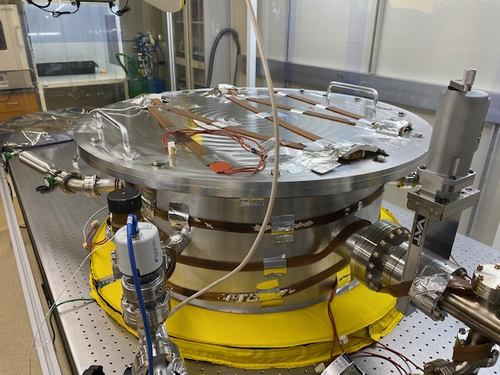

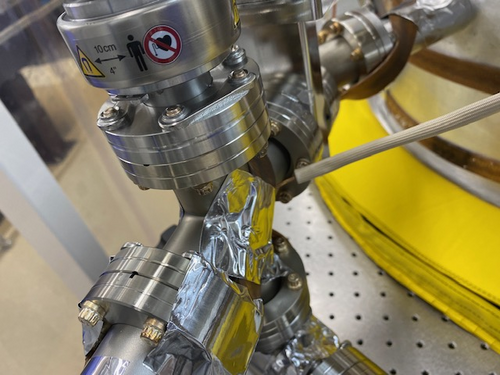

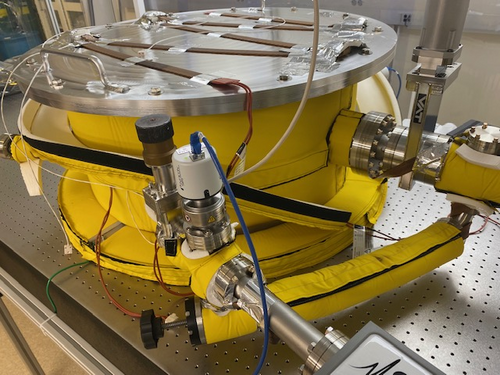

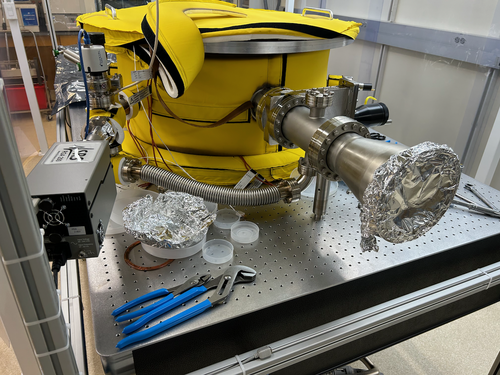

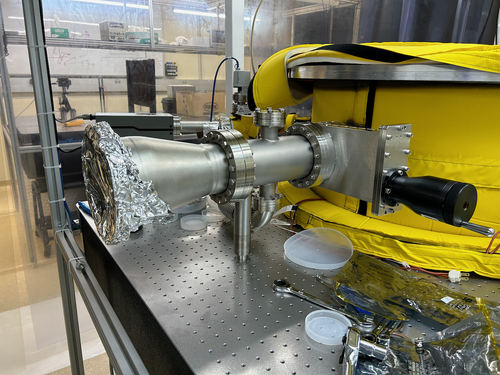

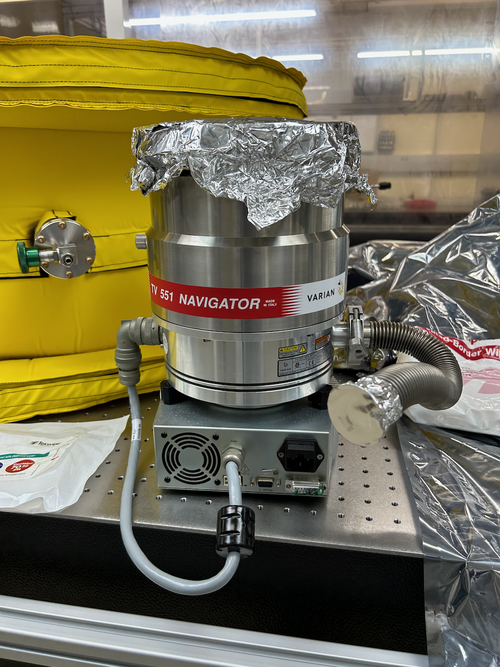

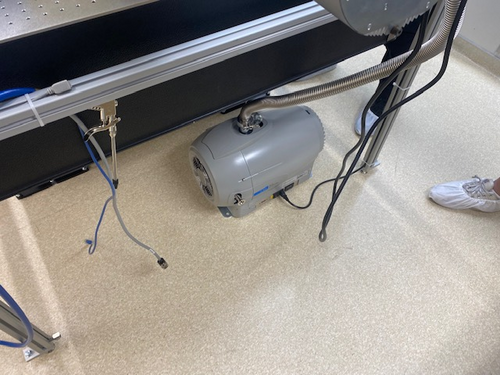

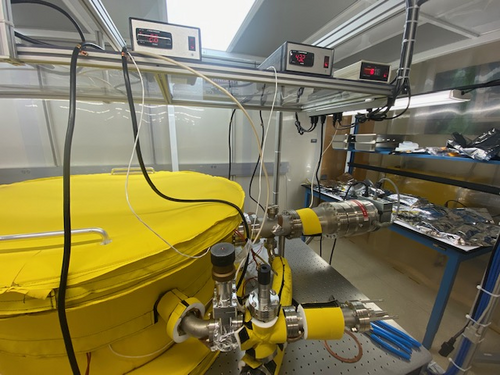

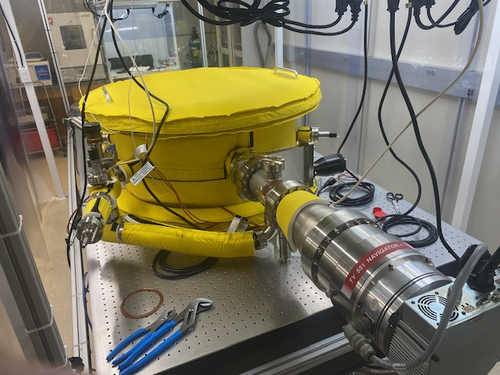

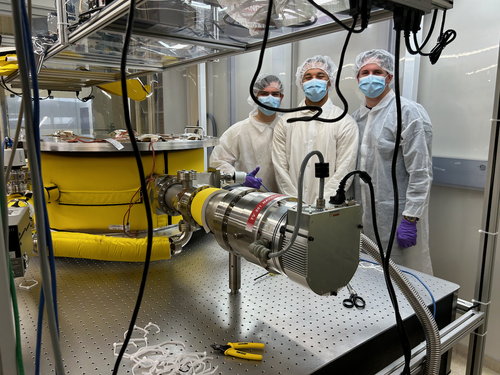

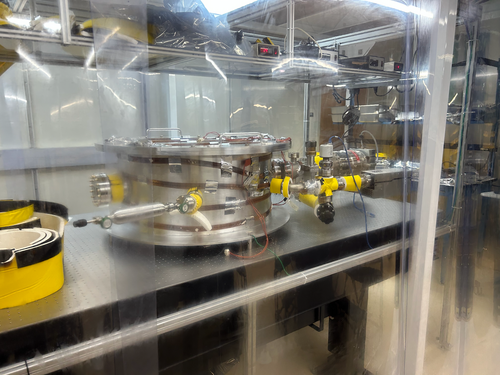

Jon | Update | VAC | Vacuum upgrade begins |

[Jon, Tyler, Aiden, Peter]

Upgrade of the UHV system to a larger turbo pump began today. After obtaining a final RGA scan in the old configuration (Aiden to post), we vented all three volumes and proceeded to disassemble the 4.5"-diameter pump line. We completed installation of the new 6"-diameter pump line to the point where the new turbo pump will attach. This includes a 6" manual gate valve, 6"/2.75" reducing cross, and 6"/8" conical reducing nipple, as pictured below. Strain relief was also installed due to the longer length and greater weight of the new fittings.

Tomorrow we will continue with attaching the Varian TV 551 pump and perform a pump-down test. If this pump is confirmed to be operable, then we will relocate the entire system ~18" closer to the middle of the table and permanentize the setup. |

| Attachment 1: IMG_0619.png

|

|

| Attachment 2: IMG_0621.png

|

|

| Attachment 3: IMG_0618.png

|

|

|

239

|

Thu Oct 12 12:11:10 2023 |

Aiden | Update | VAC | Vacuum chamber Helium leak test |

| [Aiden, Tyler, Peter, Jon]

Continued tightening bolts on the turbo pump and 6"-8" reducer to reduce the leak. The final leak test values for the turbo pump flange was 3.0 e-9 and the other 6"-8" reducer flange was 4.0 e-9.

We will continue to let it pump down as the screws could not be tightened anymore. Looks like new gaskets will be needed to reduce the leaking on these flanges.

|

| Attachment 1: IMG_4689.jpg

|

|

| Attachment 2: IMG_4688.jpg

|

|

|

240

|

Thu Oct 19 11:41:04 2023 |

Aiden | Update | VAC | Vacuum Chamber Baking Update |

| [Aiden, Tyler, Mohak]

Took some RGA data when we came into the room. The pressure of the chamber was 8.63e-8 Torr before turning on the RGA filament. We saw the usual spike in pressure when the filament was initially turned on. Took some data and saw that the chamber was definitely dirtier since the vacuum upgrade. See figures below.

Put the heater tape back onto the section that was removed. We may need to rearrange the heater tape again as there was not much heater tape to go around the upgraded section. We also tried to get some of the extra insulation around this section and we able to get some on around the 6-8 inch reducer.

We then took off the electronics for the gauges and the RGA, added the new extension cords to the PID controllers, and then started bake 6 which will go to 120 degC and stay that way until most likely Monday. The pressure before starting the bake was 8.28e-8 Torr.

|

| Attachment 1: bake5_231019_ArC.png

|

|

| Attachment 2: bake5_231019_ArO.png

|

|

| Attachment 3: IMG_4717.jpg

|

|

| Attachment 4: IMG_4716.jpg

|

|

| Attachment 5: IMG_4715.jpg

|

|

| Attachment 6: bake5_231019_ArO.png

|

|

|

241

|

Fri Oct 20 16:38:02 2023 |

Shane, Aiden | Update | Cleanroom | Cleanrooom cleaning and particle count |

|

[Aiden, Shane]

cleaning cleanroom and particle count

|

|

242

|

Mon Oct 23 07:28:57 2023 |

Peter | Update | VLC Update | VLC Mode Matching |

| I have attached a pdf with slides of my latest updates. |

| Attachment 1: Carney_VLC_Update.pdf

|

|

|

243

|

Mon Oct 23 11:28:05 2023 |

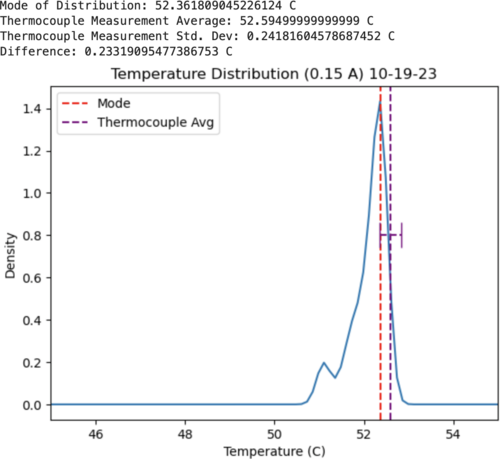

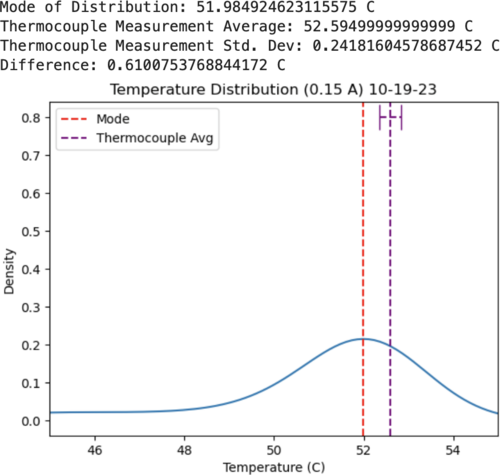

Tyler | Update | Cameras | FLIR Camera Code Updates |

| The past week I've been spending time going through the FLIR code on gitlab. Initially, it had appeared that our measurements with the camera had differed about 2 degrees C from what the thermocouple was giving (Ref ELOG 181). Upon inspection of the FLIR streaming code, I noticed a few issues:

1. The emissivity value wasn't set correctly (was 0.999 originally, should be about 0.95).

2. The ambient temperature was set to about 21.6 C (71 F).

3. The distance given before was about an inch off from what I measured.

These three parameters all must be manually specified to calculate the temperature values, and are what I assume caused the larger temperature difference seen before. I've attached a new set of measurements that I took below, where 6 images were taken by the camera, looking at a heating source with a current of 0.15 A being driven. The difference between the camera and the thermocouple were much smaller, as seen below. I'd still like to take a few more measurements to solidify that this has rectified the issue, but at the moment it seems this is working much better.

Images at: https://drive.google.com/drive/folders/1VDvZ1rfEGWsHq1AgG-chde3Cd8Do_piD?usp=sharing |

| Attachment 1: Screenshot_2023-10-23_at_11.06.04_AM.png

|

|

|

244

|

Mon Oct 23 18:02:23 2023 |

Shane, Jon | Update | CDS | Timing chassis assembly complete |

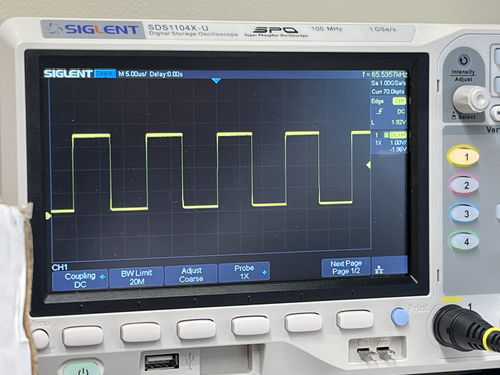

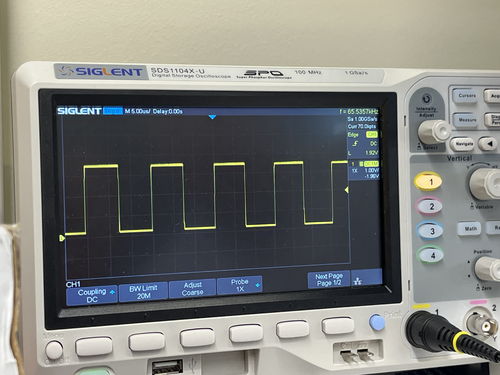

| Concluded assembly of timing chassis for CyMAC today; see attachment 1 for interior set up of chassis. Installed front and rear panels, wired on/off switch and LED assembly, and tested to confirm everything is powering on correctly. Also tested the outputted timing reference that will go to DAC and ADC adapter boards (see attachment 2 for output 1 and attachment 3 for output 2). |

| Attachment 1: timing_chassis_complete.jpeg

|

|

| Attachment 2: timing_chassis_output_1.jpeg

|

|

| Attachment 3: timing_chassis_output_2.jpeg

|

|

|

245

|

Thu Oct 26 13:00:45 2023 |

Aiden | Update | VAC | Vacuum Chamber Baking Update |

| Bake 6 was turned off on Monday. Tooke RGA data today and have posted the data below. The pressure of the chamber after taking data was 3.22 e-8 Torr. The chamber HC levels are still not low enough but I feel with more pumping it will go down as the RGA scan was still slowly going down during the data taking. |

| Attachment 1: bake6_231026_ArC.png

|

|

| Attachment 2: bake6_231026_ArO.png

|

|

|

246

|

Fri Oct 27 15:16:31 2023 |

Aiden | Update | VAC | Vacuum Leak Test |

| Leak tested the worst flanges on the chamber after moving it and after bake 6. The 6 inch flange connected to the 8 inch reducing nipple is now leaking at 1.5 e-9, previously at 4 e-9. The 8 inch flange connected to the turbo pump is now leaking at 1.9 e-9, previously at 3 e-9. This means that the baking most likely improved the seals on these flanges and a hotter bake might fix the leaks for good. |

|

247

|

Fri Oct 27 15:28:30 2023 |

Shane | Update | CDS | AA and AI chassis for CyMAC powered on and functional |

| CyMAC updates: Switched out the faulty power regulator boards in the Anti-Aliasing and Anti-Imaging chassis. Both chassis are now powering up correctly with lights on and the correct voltages in/out of the power regulator board. Images attached. All chassis for the CyMAC now functional, so next step is mounting everything in the rack. |

| Attachment 1: AI_chassis_lights_on.jpeg

|

|

| Attachment 2: AA_chassis_lights_on.jpeg

|

|

|

248

|

Mon Oct 30 08:42:22 2023 |

Jon | Update | VAC | Vacuum Leak Test |

By 5:30 pm Friday, the pressure had reached 8.6e-8 torr and was continuing to fall. So it seems we are OK to proceed with permanentizing this configuration (cable routing, heater tape reinstallation).

| Quote: |

| Leak tested the worst flanges on the chamber after moving it and after bake 6. The 6 inch flange connected to the 8 inch reducing nipple is now leaking at 1.5 e-9, previously at 4 e-9. The 8 inch flange connected to the turbo pump is now leaking at 1.9 e-9, previously at 3 e-9. This means that the baking most likely improved the seals on these flanges and a hotter bake might fix the leaks for good. |

|

| Attachment 1: IMG_0659.png

|

|

| Attachment 2: IMG_0660.png

|

|

|

249

|

Mon Oct 30 11:03:56 2023 |

Tyler | Update | Scripts/Programs | |

FLIR: After some adjustments, the plot generated from the FLIR measurements look much more symmetric (see attachment). There are more included grid points, which smooths out the curve as compared to last week.

Red Pitaya: It looks like a new OS update was released for the RP, which includes a new Python API (was previously only available in C). I'm going to try and update the one we have currently running in lab.

|

| Attachment 1: Screenshot_2023-10-23_at_12.39.05_PM.png

|

|

|

250

|

Mon Oct 30 18:15:13 2023 |

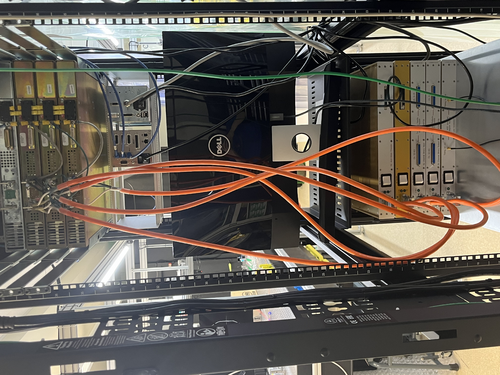

Shane | Update | CDS | CyMAC chassis mounted and progress on power connections |

| All CyMAC chassis mounted in electronics rack today, and shelf for monitor also mounted. Images attached. Assembled grounding cables for power connections, and attached the timing chassis to power & gnd. Powered on successfully with correct voltages in expected places. After power test, everything was turned off and unplugged. Next steps: attach grounding cables to other four power supply chassis. Also attach anti-aliasing, anti-imaging, binary input and binary output chassis to power supply. |

| Attachment 1: electronics_rack_back.jpeg

|

|

| Attachment 2: electronics_rack_front.jpeg

|

|

| Attachment 3: mounted_chassis.jpeg

|

|

| Attachment 4: power_supply.jpeg

|

|

|

251

|

Tue Oct 31 19:46:35 2023 |

Aiden | Update | VAC | VAC System Heating Update |

| Started bake 7 on Monday but found issues with the heating as the cross in front of the RGA got way too hot too quickly. This resulted in shutdowns of the heater tape while I could still only set the main PID controller for the lid to 75C. Tuesday I moved the PID controller sensors to be on the cross in front of the RGA and on the Reducing nipple. I then placed the alarm sensors onto the lid of the chamber and the barrel. This should hopefully prevent excessive heating on then smaller components. I also started the bake again Tuesday, but only set the temperature to 85C for now and will increase it further tomorrow when I get a good idea of the equilibrium point of the chamber. |

| Attachment 1: IMG_4745.jpg

|

|

| Attachment 2: IMG_4744.jpg

|

|

|

252

|

Wed Nov 1 18:24:01 2023 |

Shane | Update | CDS | CyMAC Power connections made |

Finished power connections today for the CyMAC chassis. Images attached. Had to switch the shrink fork terminals on the power supply cables to shrink ring terminals, but was able to get everything connected and secured. Upcoming work: turning on power supply and testing voltages/checking everything is turning on and lighting up correctly.

Configuration is as follows:

- Topmost Sorensen: +24V (reserved for FROSTI)

- Negative terminal: [negative terminal is grounded]

- jumper to Sorensen ground screw

- Sorensen 2nd from the top: +18V

- Positive terminal:

- white power cable wire for AA chassis

- white power cable wire for AI chassis

- white power cable wire for BI chassis

- white power cable wire for BO chassis

- Negative terminal: [negative terminal is grounded]

- jumper to Sorensen ground screw

- black power cable wire for AA chassis

- black power cable wire for AI chassis

- black power cable wire for BI chassis

- black power cable wire for BO chassis

Sorensen 3rd from the top: -18V

- Positive terminal:[positive terminal is grounded]

- jumper to Sorensen ground screw

- green power cable wire for BI chassis

- green power cable wire for BO chassis

- Negative terminal:

- green power cable wire for AA chassis

- green power cable wire for AI chassis

Bottommost Sorensen: +6V

- Positive terminal:

- white power cabe wire for timing chassis

- Negative terminal: [negative terminal is grounded]

- jumper to Sorensen ground screw

- green power cable wire for timing chassis

- black power cable wire for timing chassis

|

| Attachment 1: cymac_power_connected.jpeg

|

|

| Attachment 2: cymac_power_connections_back.jpeg

|

|

|

253

|

Wed Nov 1 20:22:07 2023 |

Aiden | Update | VAC | VAC System Heating Update |

| Raised the PID controller temperature to 105C today as at that temperature the lid and the barrel temperature sensors were reading around 120C. I will check again tomorrow to see if there is any room for increase after equilibrium. |

|

254

|

Thu Nov 2 17:14:36 2023 |

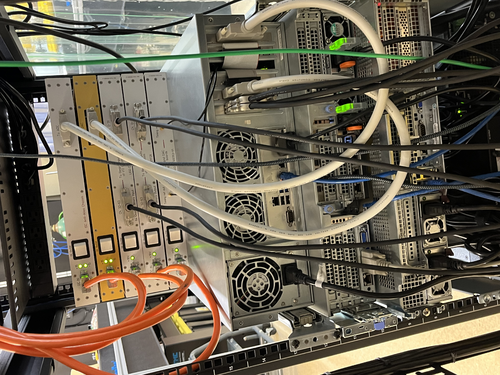

Shane, Jon | Update | CDS | CyMAC set up permanentized |

|

CyMAC connections have been finalized and made permanent. Also tested voltages, which are all looking good. Warning: power is on. Do not touch power supply terminals or screws connected to grounding cables (see attached images 4 and 5; green wires on back of power supply with black and yellow covers, and exposed positive and negative terminals on back of power supply).

Also established connections from Anti-Aliasing chassis to ADC adapter board, Anti-Imaging chassis to DAC adapter board, and binary in/out chassis to BIO card, all mounted within Cymac host computer. Turned on CyMAC and ran test model, received error message likely pointing to timing signal not being successfully passed to the adapter boards. Next steps are checking to make sure correct timing signal is actually being output, and then checking internal ribbon cable in host chassis, which is another potential cause of the error.

|

| Attachment 1: cymac_chassis_back.jpeg

|

|

| Attachment 2: cymac_chassis_back2.jpeg

|

|

| Attachment 3: cymac_chassis_front.jpeg

|

|

| Attachment 4: final_connections_back_of_power_supply.jpeg

|

|

| Attachment 5: power_supply_back.jpeg

|

|

|

255

|

Mon Nov 6 11:29:24 2023 |

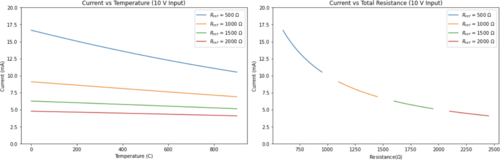

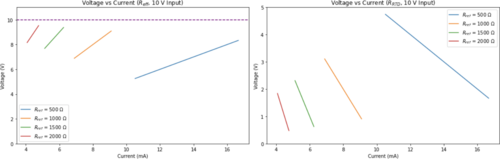

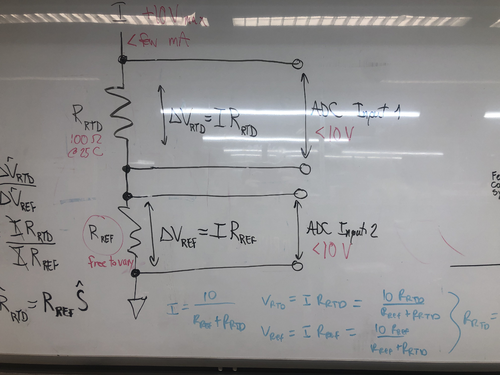

Tyler | Update | Electronics | Preliminary RTD Calculations, RP Software Update |

Preliminary RTD calculations are shown below, given an input of 10 V and desiring a few mA of current. It looks like R_ref should be at least 1 kOhm (refer to plots/circuit below), keeping in mind we need to have <10 V input for the ADC.

RP: The Red Pitaya Software was updated to OS 2.00. All examples on the RP website should run without issue. |

| Attachment 1: cvt.png

|

|

| Attachment 2: VvC.png

|

|

| Attachment 3: IMG_7471.jpg

|

|

|

256

|

Mon Nov 6 11:31:25 2023 |

Peter | Update | VLC Update | VLC Mode Matching |

| See Update Attached |

| Attachment 1: VLC_Update_11_6_23.pdf

|

|

|

257

|

Wed Nov 8 17:55:49 2023 |

Jon | Update | General | Lab Clean-Up Day 1 |

[Jon, Tyler, Shane, Peter, Luis]

Today we completed the first phase of lab clean-up. Activities included:

- CF/KF parts stored under the cleanroom table were removed and transferred to Physics 1129

- Cleanroom workbench cleared, with all FROSTI hardware collected into one of the large SS bins

- High surfaces outside the cleanroom (lights, table enclosure frames, rack, cabinets) wiped down with IPA wipes

- Floor HEPA-vacuumed outside the cleanroom

- Sticky mats changed throughout the lab

Tomorrow, we will complete turn-over of the cleanroom (HEPA vacuuming of floors, mopping of floors, IPA wiping of softwalls and work surfaces). Shane will post a forthcoming measurement of the cleanroom particulate levels, post-turnover. |