|

ligo-ex

ligo-ds

|

| Richardson Lab Experimental Log |

Not logged in |

|

|

|

Thu Apr 27 16:23:44 2023, Cao, Pamella and Julian, Physics, VAC, Installing vacuum system (cont.) Thu Apr 27 16:23:44 2023, Cao, Pamella and Julian, Physics, VAC, Installing vacuum system (cont.)

|

Thu Apr 27 21:43:07 2023, Jon, Physics, VAC, Grounding vacuum system Thu Apr 27 21:43:07 2023, Jon, Physics, VAC, Grounding vacuum system

|

Fri Apr 28 18:16:57 2023, Cao, Physics, VAC, Grounding vacuum system Fri Apr 28 18:16:57 2023, Cao, Physics, VAC, Grounding vacuum system

|

|

|

Message ID: 81

Entry time: Thu Apr 27 16:23:44 2023

Reply to this: 82

|

| Author: |

Cao, Pamella and Julian |

| Type: |

Physics |

| Category: |

VAC |

| Subject: |

Installing vacuum system (cont.) |

|

|

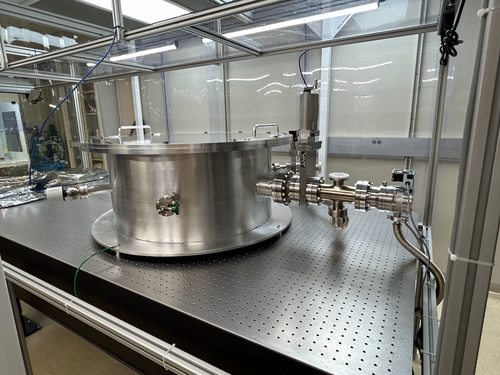

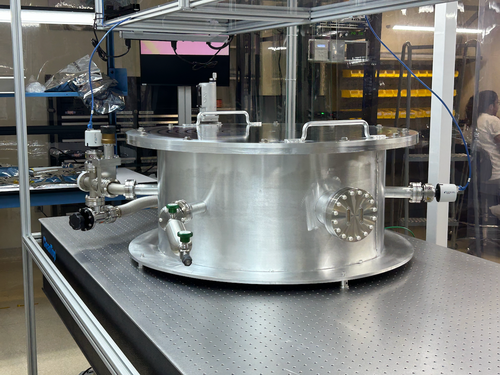

[Pamella, Cao and Julian, Shane]

- Particles account

- 10:37 am: Starting the particles account

- Zone 3:

- 0.3u: 1662

- 0.5u: 872

- 1.0u: 415

- Zone 4:

- 0.3u: 831

- 0.5u: 124

- 1.0u: 0

- 11:14 am: Start removal of calibrated leak to install 45 deg elbow

- 11:21 am: Elbow installed, re-install calibrated leak back on

- 11:29 am: Finished re-install calibrated leak, start installing gate valve on pump line

- 11:47 am: Finished installing gate valve, start installing reducing cross onto gate valve

- 12:02 pm: Finished installing reducing cross, start installing 90 deg elbow to reducing cross

- 12:17 pm: Finished installing reducing cross, lunch break

- 01:24 pm: Come back to the lunch break.

- 01:26 pm: Start installing vacuum hose to elbow.

- 01:40 pm: Finished installing vacuum hose.

- 01:43 pm: Start installing turbo pump.

- 02:00 pm: finished installing turbo pump .

- 02:10 pm: Start installing standard wall hose from turbo pump to scroll pump

- 02:21 pm: finished installing hose onto scroll pump, start installing lid. Remove lid from chamber, insert viton O-ring. Place lid back

- 02:30 pm: Secure lids with screw. Start installing turbo pump controller cable: Pass cable from outside (controller) up the top of clean tent and connect to 8 pin connector on turbo pump

- 03:00 pm: Installing air cooling unit for turbo pump, found 8 M3 screws for air cooling unit in the C&B cabinet to install the fan bracket onto the back of turbo pump. Fan control cable is routed up to the top of the cleanroom to the controller

- 03:15 pm: Installing full-range gauge cable to the controller outside cleanroom. Ethernet cables 1 and 2 are used. Cable 1 is used on the RGA line gauge. Cable 2 is connected to the main body gauge. Cable1 and 2 are connected controller's channel 1 and 2 respectively.

- 04:00 pm: Finish installing gauges cables. Cables are routed up along the frame to the controller sitting outside the cleanroom

- 04:15 pm: Finished. End-of-date particle count

- Zone 3:

- 0.3u: 3699

- 0.5u: 1454

- 1.0u: 872

- Zone 4:

- 0.3u: 1662

- 0.5u: 706

- 1.0u: 290

|

|

|

|

|